Ginseng royal jelly chewable tablets and preparation method thereof

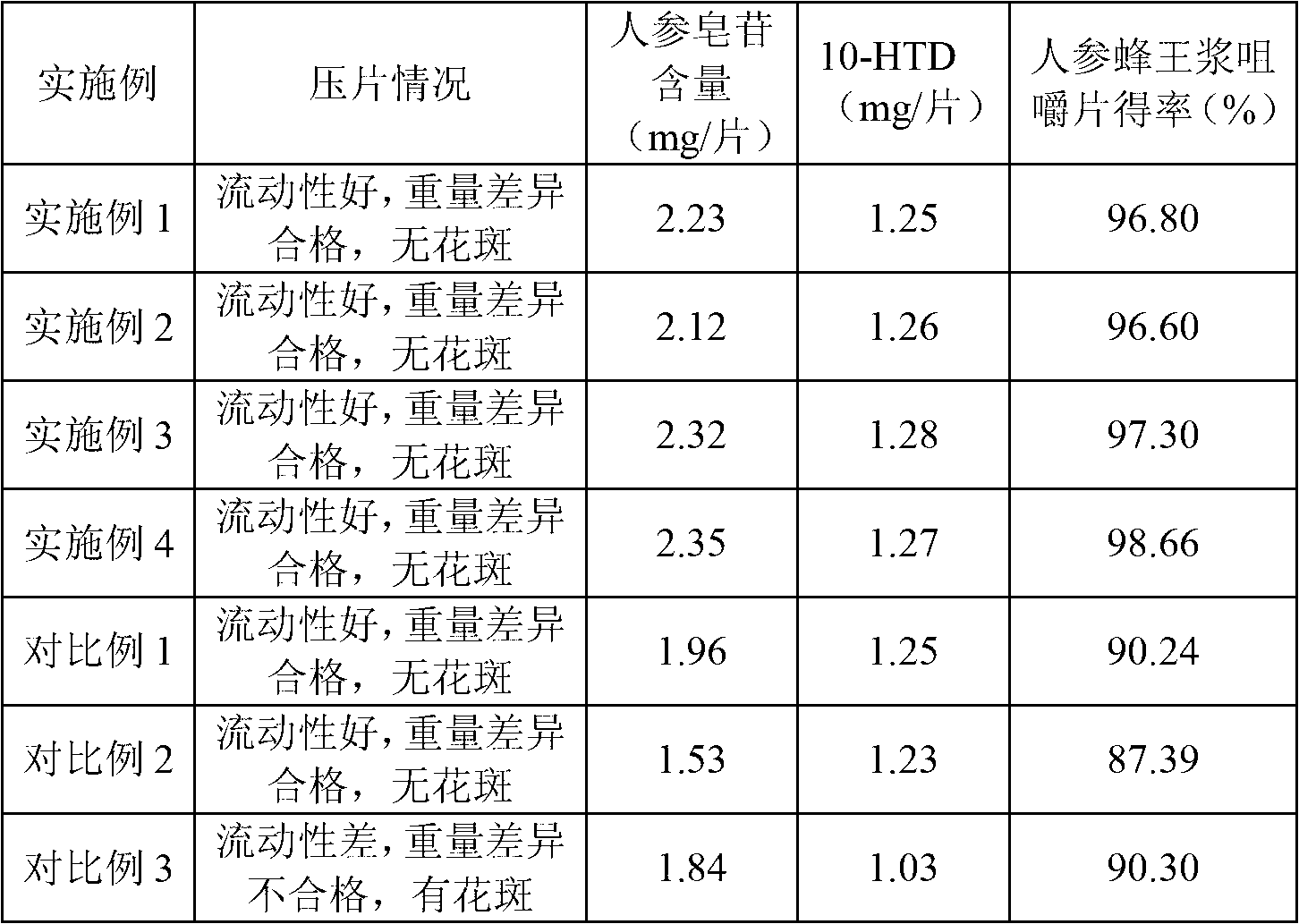

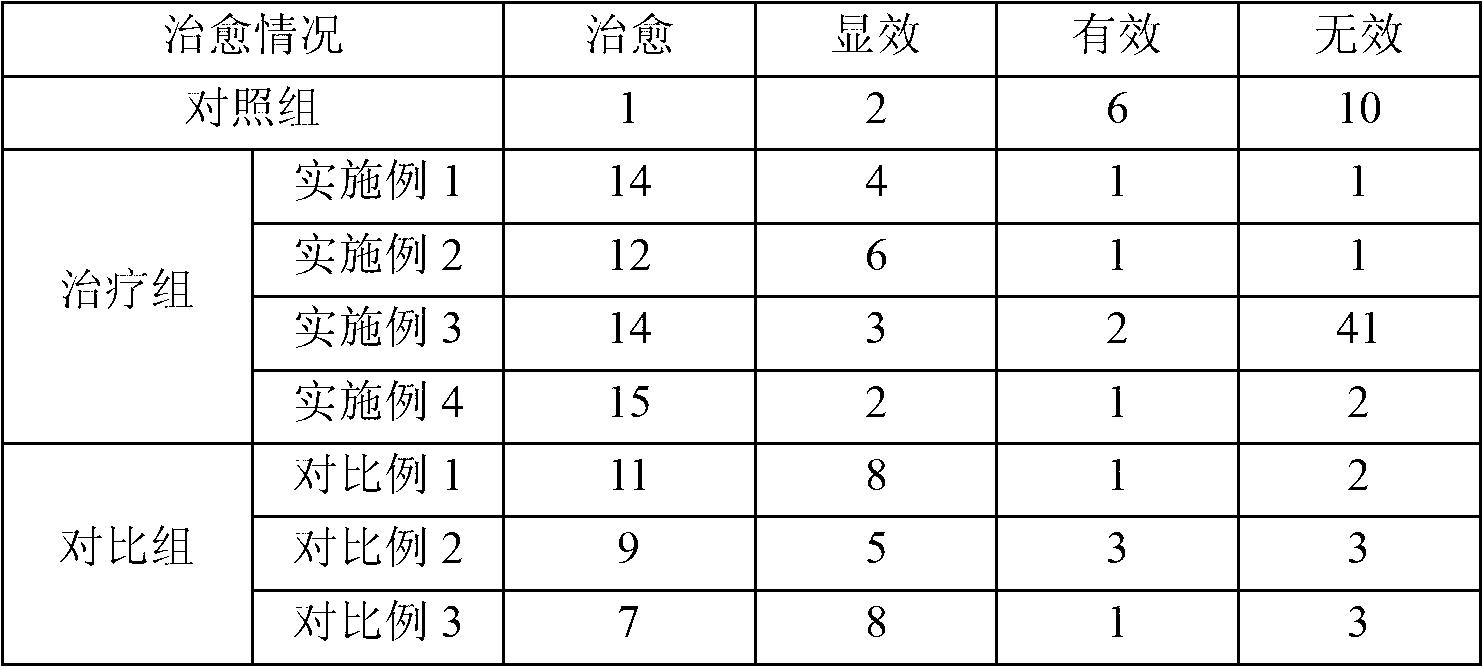

A technology for royal jelly and chewable tablets, applied in the field of ginseng royal jelly chewable tablets, can solve the problems of ginseng loss, low yield, low bioavailability, etc., and achieve the effects of qualified weight difference, high extraction rate and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a preparation method of ginseng royal jelly chewable tablet, comprising:

[0018] 1) Take 100 parts by weight of royal jelly and add 3 to 7 parts by weight of starch and mix them evenly to obtain a royal jelly starch mixture. The royal jelly starch mixture is subjected to a freeze-drying step to obtain a royal jelly freeze-dried product, and the royal jelly freeze-dried product is ball-milled to obtain a royal jelly freeze-dried powder.

[0019] 2) Take 100 parts by weight of ginseng, vacuum-dry it at 80° C. and immediately cool it to 0° C. to obtain a dried ginseng product.

[0020] 3) The dried ginseng product is pre-crushed into ginseng coarse powder, and the ginseng coarse powder is subjected to a low-temperature vibration ultrafine pulverization step to obtain ginseng fine powder with a particle size of 12-15 μm.

[0021] 4) Mix ginseng micropowder with 200-300 parts by weight of filler, 120-250 parts by weight of flavoring agent, 80-120 part...

Embodiment 1

[0038] 1) Take 100 parts by weight of royal jelly and 3 parts by weight of starch and mix evenly to obtain a royal jelly starch mixture; pre-freeze the royal jelly starch mixture at -40°C for 5 hours; then heat the royal jelly starch mixture to make the royal jelly starch mixture at -25 ℃, and the vacuum degree is -10pa for 8 hours; finally, the royal jelly starch mixture is heated to 25 ℃ and taken out to obtain a royal jelly freeze-dried product; the royal jelly freeze-dried product is ball-milled into a royal jelly freeze-dried powder.

[0039] 2) Take 100 parts by weight of ginseng, vacuum-dry it at 80° C., and then quickly freeze it to 0° C. to obtain a dried ginseng product.

[0040] 3) Dried ginseng was pre-crushed into coarse powder, filled with nitrogen, and vibrated and ultrafinely pulverized with stainless steel balls at -40°C for 15 minutes to obtain ginseng micropowder with a particle size of 15 μm, and the filling rate of the medium was 75%.

[0041] 4) Mix ginse...

Embodiment 2

[0044] 1) Take 100 parts by weight of royal jelly and 5 parts by weight of starch and mix evenly to obtain a royal jelly starch mixture; pre-freeze the royal jelly starch mixture at a temperature of -40°C for 5 hours; then heat the royal jelly starch mixture to make the royal jelly starch mixture at a temperature of -25 ℃, and the vacuum degree is -10pa for 8 hours; finally, the royal jelly starch mixture is heated to 25 ℃ and taken out to obtain a royal jelly freeze-dried product; the royal jelly freeze-dried product is ball-milled into a royal jelly freeze-dried powder.

[0045] 2) Take 100 parts by weight of ginseng, vacuum-dry it at 80° C., and then quickly freeze it to 0° C. to obtain a dried ginseng product.

[0046] 3) Dried ginseng was pre-crushed into coarse powder, filled with nitrogen, and vibrated and ultrafinely pulverized with stainless steel balls at -40°C for 20 minutes to obtain ginseng micropowder with a particle size of 12 μm, and the filling rate of the medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com