Method for treating waste water generated from surface treatment of aluminum products

A surface treatment and treatment method technology, which is applied in the field of waste water classification treatment process, to reduce the use of additives, reduce labor intensity and other costs, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

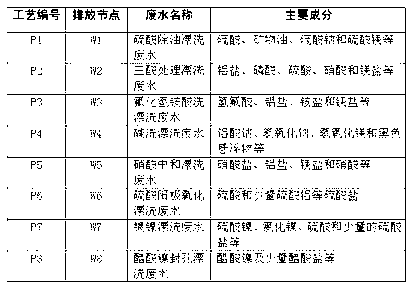

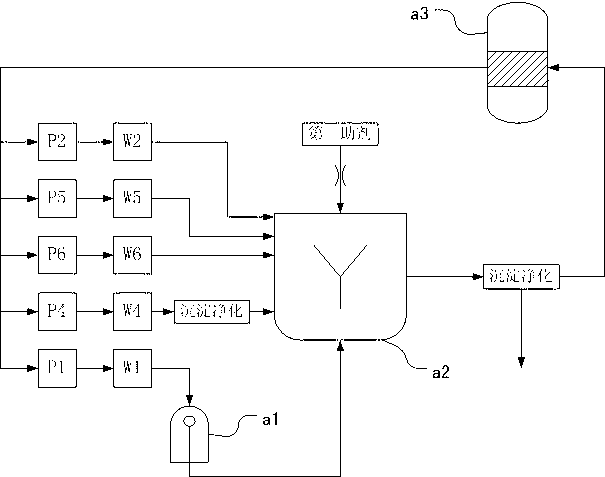

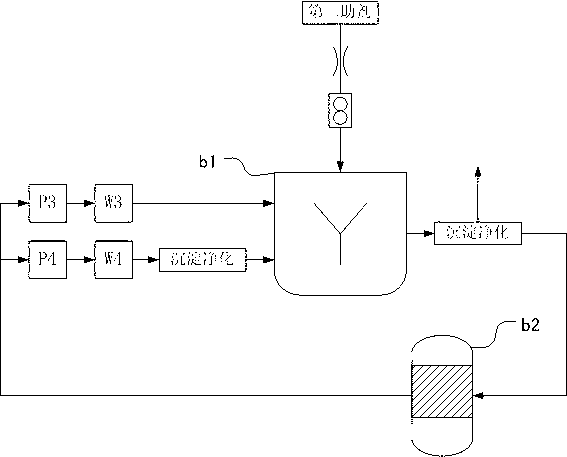

Method used

Image

Examples

Embodiment 1

[0042] S101: Take 200ml of sulfuric acid degreasing and rinsing waste water, irradiate it in a microwave oven with a power of 4Kw and a frequency of 915MHz for 2 minutes, use a separatory funnel to separate water and oil, and remove about 2.5ml of oil.

[0043] S102: Mix 150ml of microwave degreased water, 150ml of tri-acid rinsing wastewater, 150ml of sulfuric acid anodizing rinsing wastewater and 150ml of nitric acid neutralizing rinsing wastewater, add 120ml of pre-filtered and purified alkaline washing rinsing wastewater, stir to neutralize and add triphosphate Sodium 2.5 and polyacrylamide ammonium (concentration 0.1%) aqueous solution 5ml, wastewater pH value is 7.5, centrifugal filtration to obtain 24.5g aluminum phosphate, the hardness of the filtered water is 95.4mg / L, which meets the requirements of recycling.

[0044] S103: Add 200ml of ammonium bifluoride pickling and rinsing wastewater to 54ml of pre-filtered and purified alkali washing and rinsing wastewater. The ...

Embodiment 2

[0047] S201: Take 200ml of sulfuric acid degreasing and rinsing wastewater, irradiate it in a microwave oven with a power of 2Kw and a frequency of 915MHz for 1 minute, use a separatory funnel to separate water and oil, and remove about 2.1ml of oil.

[0048] S202: Mix 150ml of microwave degreased water, 120ml of tri-acid rinsing wastewater, 150ml of sulfuric acid anodizing rinsing wastewater and 150ml of nitric acid neutralizing rinsing wastewater, add 150ml of pre-filtered and purified alkaline washing rinsing wastewater, stir to neutralize and add 3.5g Trisodium phosphate and ammonium polyacrylamide (concentration: 0.1%) aqueous solution was 2.5ml, the pH value of the waste water was 9, 25.3g of aluminum phosphate was obtained by centrifugal filtration, and the hardness of the filtered water was 101.7mg / L, which met the requirement of recycling.

[0049] S203: Add 100ml of ammonium bifluoride pickling and rinsing wastewater to 40ml of pre-filtered and purified alkali washing...

Embodiment 3

[0052] S301: Take 200ml of sulfuric acid degreasing and rinsing waste water, irradiate it in a microwave oven with a power of 5Kw and a frequency of 915MHz for 5 minutes, and use a separatory funnel to separate water and oil to remove about 2.7ml of oil.

[0053] S302: Mix 150ml of microwave degreased water, 150ml of tri-acid rinsing wastewater, 150ml of sulfuric acid anodizing rinsing wastewater and 150ml of nitric acid neutralizing rinsing wastewater, add 100ml of pre-filtered and purified alkaline washing rinsing wastewater, stir to neutralize and add triphosphate Sodium 1.5g and polyacrylamide ammonium (concentration 0.4%) aqueous solution 4ml, wastewater pH value is 5, aluminum phosphate 23.6g is obtained by centrifugal filtration, and the hardness of filtered water is 101.4mg / L, which meets the requirements of recycling.

[0054] S303: Add 200ml of ammonium bifluoride pickling and rinsing wastewater to 40ml of pre-filtered and purified alkali washing and rinsing wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com