Method for adsorbing and extracting 1,3-propanediol from zymotic fluid by using cationic resin

A cationic resin, adsorption and extraction technology, applied in the field of separation of microbial fermentation products, can solve the problems of 1,3-propanediol recovery research that has not yet been carried out, existing methods are complicated, and the amount of fermentation liquid is large, so as to reduce material consumption, low cost, The effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The fermented broth treated in this example uses waste glycerol as a substrate, and is fermented by Clostridium butyricum to produce 1,3-propanediol fermented broth, with a pH of 7.0 at the end of fermentation; wherein the concentration of 1,3-propanediol is 52 g / L, glycerin The concentration is 2g / L.

[0042] (1) Take the above fermentation broth, add 1wt% flocculant and 0.2wt% powdered activated carbon, stir for 60min, let stand and settle naturally;

[0043] (2) Remove bacteria and protein by plate and frame filtration to obtain supernatant;

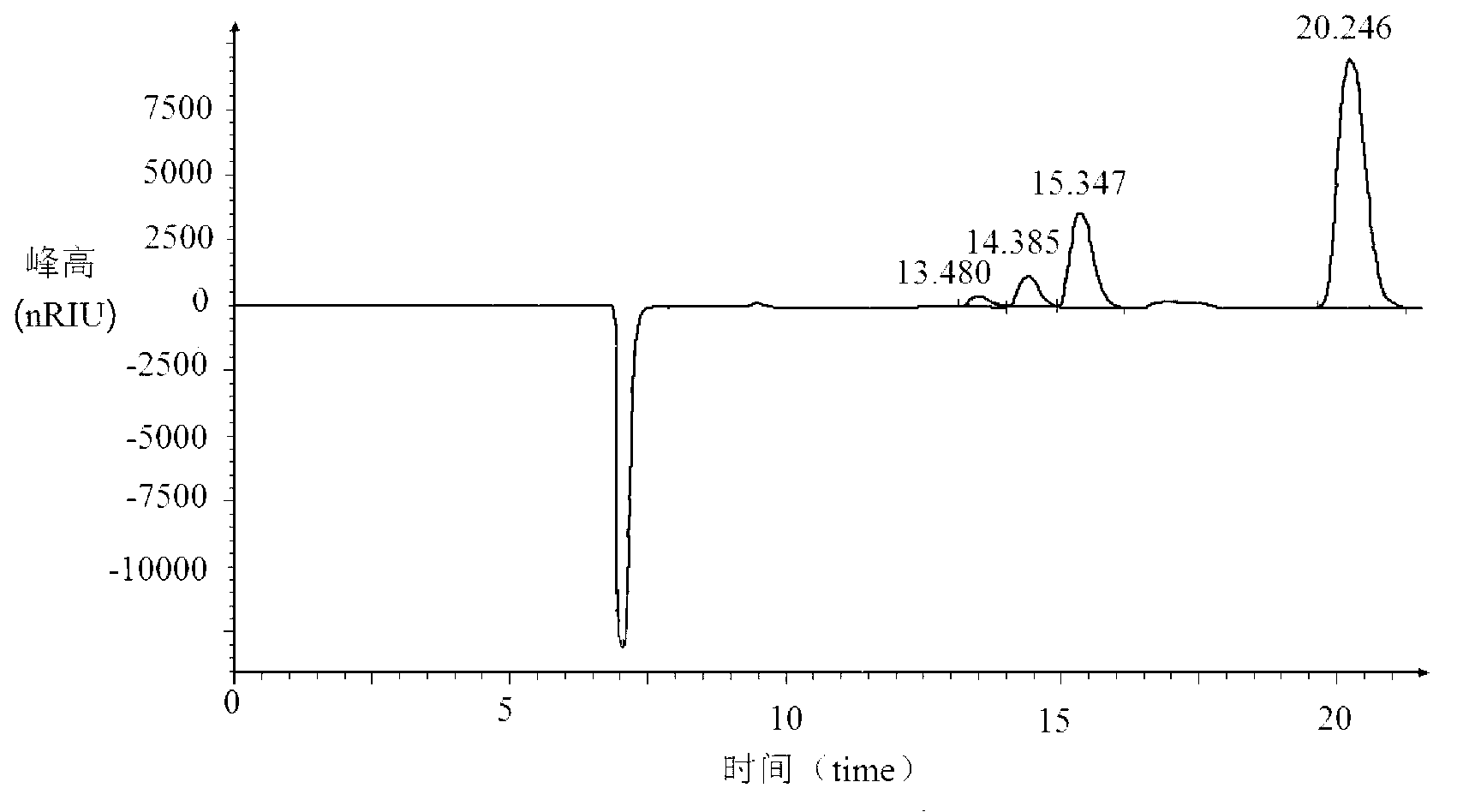

[0044] (3) At 25°C, add 1.0g of wet resin and an appropriate amount of supernatant to a 250mL Erlenmeyer flask, place the Erlenmeyer flask on a constant temperature shaker, and perform adsorption at 150r / min. When 1,3- When the concentration of propylene glycol no longer changes, it means that the resin has reached saturation; then measure the concentration of 1,3-propanediol in the solution, and calculate the saturated adsorp...

Embodiment 2

[0049] The fermented broth treated in this example uses waste glycerol as a substrate, and is fermented by Clostridium butyricum to produce 1,3-propanediol fermented broth. The pH at the end of fermentation is 7.0, and the concentration of 1,3-propanediol is 52 g / L.

[0050] (1) Take a certain amount of the above fermentation broth, adjust the pH to 1.0 with 2moL / L sulfuric acid, add 3wt% chitosan and 0.3wt% powdered activated carbon, stir at 150r / min for 30min, and let it settle.

[0051] (2) Centrifuge at 3000r / min after the flocs are completely precipitated to obtain a colorless and transparent supernatant.

[0052] (3) Take 20g of 001×4 resin and fill it in a glass column with an inner diameter of 1.0cm to prepare the adsorption column I, put the supernatant on the column, control the flow rate at 0.5mL / min, and reach saturation after 90min of adsorption, it can be known that 001× 4 The equilibrium adsorption capacity of the resin is 105.2 mg / g.

[0053] (4) Wash away imp...

Embodiment 3

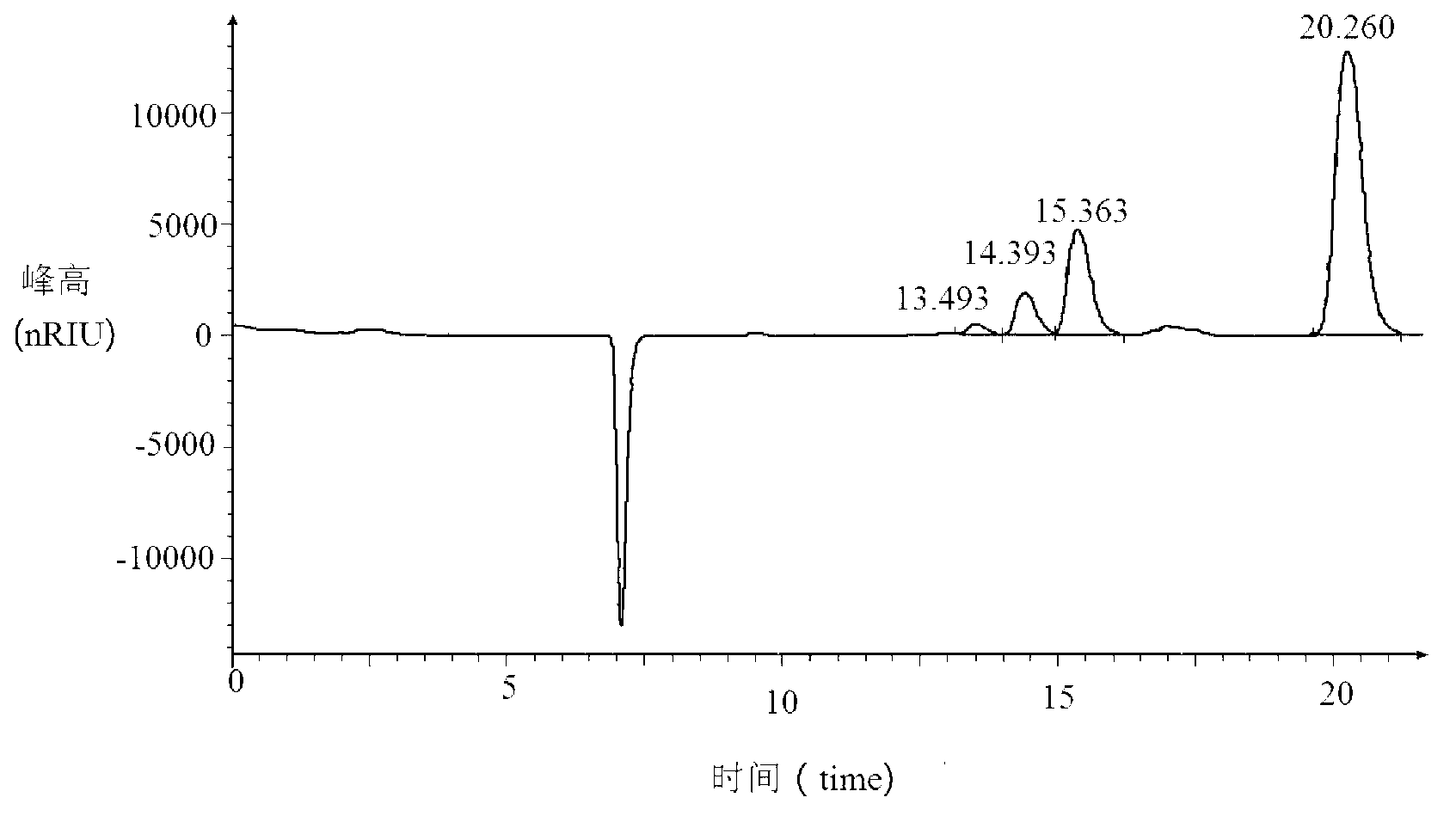

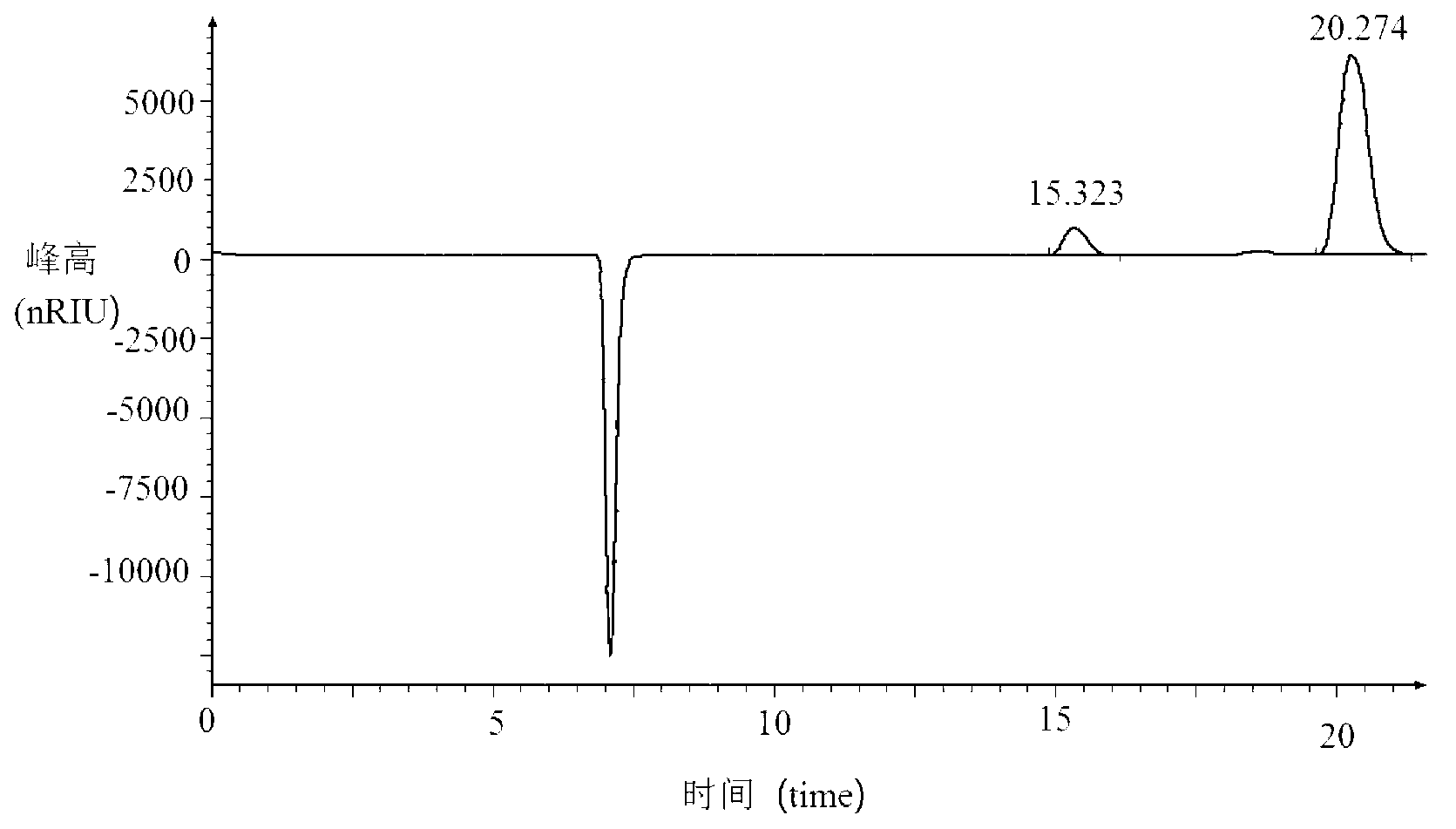

[0058] The fermented broth treated in this example uses waste glycerol as a substrate, and is fermented by Clostridium butyricum to produce 1,3-propanediol fermented broth. The pH of the fermentation end is 7.0, and the concentration of 1,3-propanediol is 56.5 g / L.

[0059] (1) Take a certain amount of the above-mentioned fermentation broth, adjust it to pH 3.0 with 2moL / L hydrochloric acid, add 5wt% chitosan and 0.5wt% powdered activated carbon, stir at 150r / min for 30min, and let it settle;

[0060] (2) After the flocs are completely precipitated, they are filtered through a plate frame to obtain a colorless and transparent supernatant;

[0061] (3) Take 20g of D101 resin and fill it into a glass column with an inner diameter of 1.0cm to prepare an adsorption column II. Put the supernatant on the column for adsorption, the flow rate is controlled at 2.0mL / min, and it reaches saturation after 30 minutes of adsorption. It can be seen that the D101 resin The equilibrium adsorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com