Method for synchronously extracting vegetable seed oil and protein

A technology of simultaneous extraction and rapeseed oil, applied in the field of simultaneous extraction of rapeseed oil and protein, to achieve the effects of safe operation, high protein yield and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

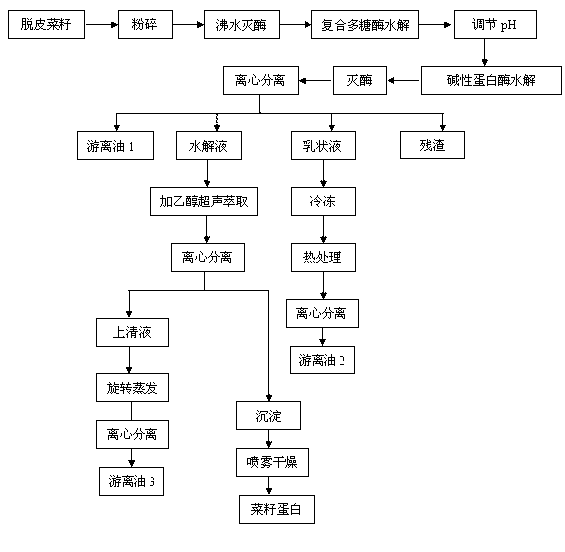

Image

Examples

Embodiment 1

[0017] Weigh 100 g of peeled and crushed rapeseed and add 500 ml of distilled water to mix to obtain a mixed solution, boil the mixed solution for 5 minutes, adjust the pH of the mixed solution to 5.0 after cooling, add complex polysaccharide enzymes (pectinase, cellulase and β-glucan Enzyme compounded at 4:1:1) Hydrolyzed at 45°C for 2 hours to obtain enzymatic solution 1, adjust the pH of enzymatic solution 1 to 9.0, add protex-6L alkaline protease and enzymolyze at 55°C for 1 hour to obtain enzymatic solution 2. Centrifuge the enzymatic solution 2 to obtain hydrolyzate, emulsion, free oil 1 and residue; (2) Freeze the emulsion obtained in step (1) for 2 hours, heat at 90°C for 10 minutes, and then centrifuge to obtain free oil 2; ( 3) Collect the hydrolyzate obtained in step (1), add ethanol for ultrasonic extraction, the volume ratio of the added amount of ethanol to the hydrolyzate is 1:1, the ethanol concentration is 80%, the ultrasonic time is 20min, and centrifuged afte...

Embodiment 2

[0019] Weigh 100 g of peeled and crushed rapeseed and add 500 ml of distilled water to mix to obtain a mixed solution, boil the mixed solution for 5 minutes, adjust the pH of the mixed solution to 5.0 after cooling, add complex polysaccharide enzymes (pectinase, cellulase and β-glucan Enzyme compounded at 4:1:1) Hydrolyzed at 45°C for 2 hours to obtain enzymatic solution 1, adjust the pH of enzymatic solution 1 to 9.0, add protex-6L alkaline protease and enzymolyze at 55°C for 1 hour to obtain enzymatic solution 2. Centrifuge the enzymatic solution 2 to obtain hydrolyzate, emulsion, free oil 1 and residue; (2) Freeze the emulsion obtained in step (1) for 2 hours, heat at 90°C for 10 minutes, and then centrifuge to obtain free oil 2; ( 3) Collect the hydrolyzate obtained in step (1), add ethanol for ultrasonic extraction, the volume ratio of the added amount of ethanol to the hydrolyzate is 0.5:1, the ethanol concentration is 60%, the ultrasonic time is 30min, and centrifuged af...

Embodiment 3

[0021] Weigh 100 g of peeled and crushed rapeseed and add 500 ml of distilled water to mix to obtain a mixed solution, boil the mixed solution for 5 minutes, adjust the pH of the mixed solution to 5.0 after cooling, add complex polysaccharide enzymes (pectinase, cellulase and β-glucan Enzyme compounded at 4:1:1) Hydrolyzed at 45°C for 2 hours to obtain enzymatic solution 1, adjust the pH of enzymatic solution 1 to 9.0, add protex-6L alkaline protease and enzymolyze at 55°C for 1 hour to obtain enzymatic solution 2. Centrifuge the enzymatic solution 2 to obtain hydrolyzate, emulsion, free oil 1 and residue; (2) Freeze the emulsion obtained in step (1) for 2 hours, heat at 90°C for 10 minutes, and then centrifuge to obtain free oil 2; ( 3) Collect the hydrolyzate obtained in step (1), add ethanol for ultrasonic extraction, the volume ratio of the added amount of ethanol to the hydrolyzate is 0.5:1, the ethanol concentration is 60%, the ultrasonic time is 30min, and centrifuged af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com