Pressure sensor and preparation method thereof

A pressure sensor and pressure-sensitive element technology, which is applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, and the measurement of the property force of piezoelectric resistance materials, which can solve the problem of packaging. Low efficiency, unfavorable pressure sensor preparation, incompatibility of wafer-level packaging, etc., to achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

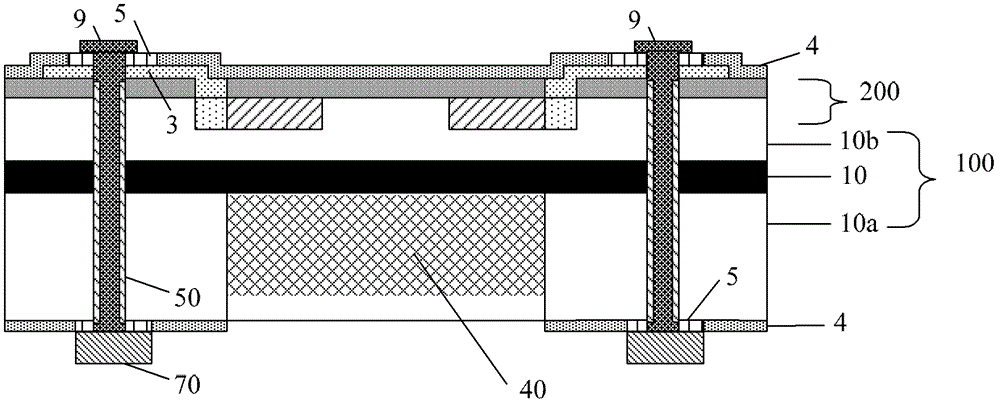

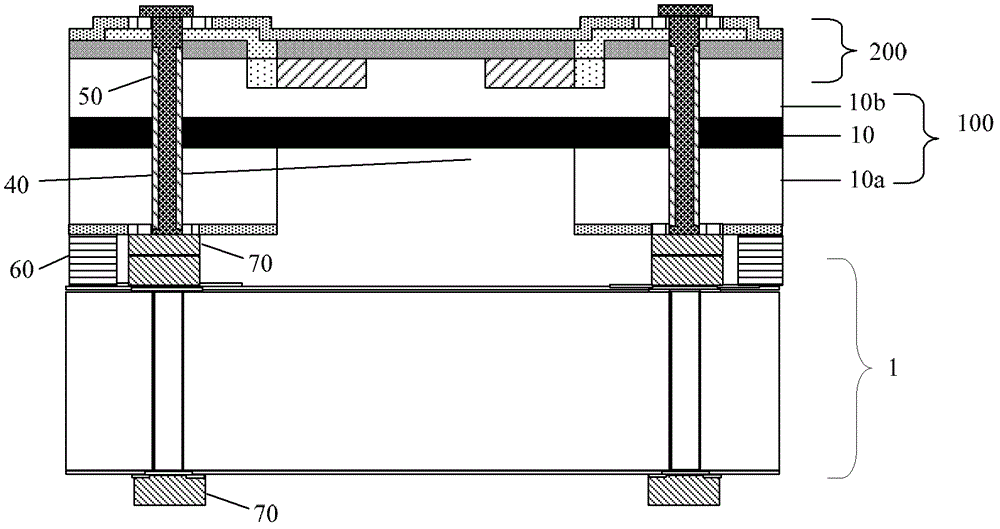

[0020] The pressure sensor and its preparation method according to the present invention will be described in detail below with reference to the accompanying drawings.

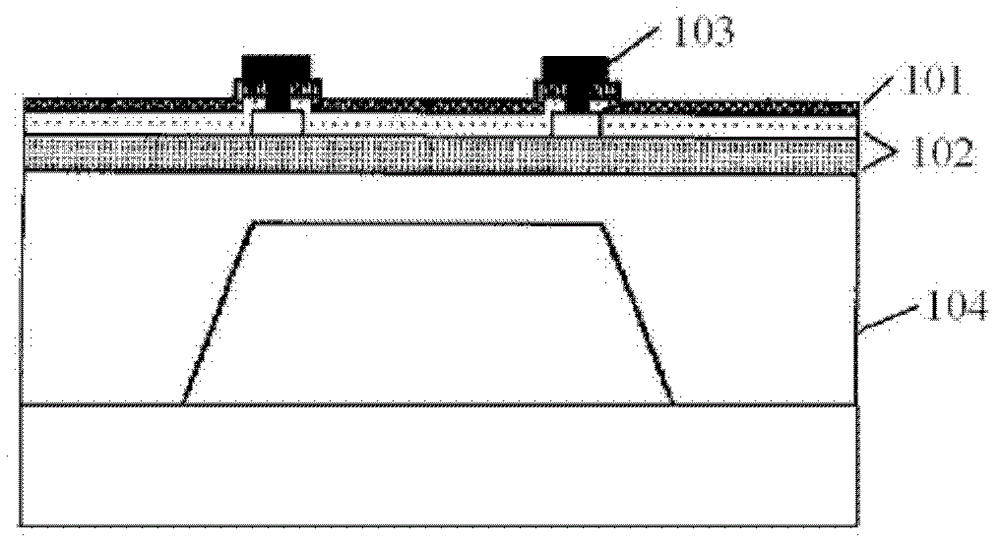

[0021] Such as figure 2 As shown, the pressure sensor according to the present invention includes a substrate 100, a pressure-sensitive element 200 and its lead electrode, and a through silicon via 50, wherein the pressure-sensitive element 200 and its lead electrode are located on one side of the substrate 100, The through silicon via 50 penetrates the substrate 100 and one end of the through silicon via 50 is interconnected with the lead electrode of the pressure sensitive element 200, and the other end of the through silicon via 50 serves as the output of the pressure sensor At the end, the pressure sensor further includes a sealed cavity 40 under the pressure sensitive element 200, and a pressure sensitive film is formed between the pressure sensitive element 200 and the sealed cavity 40.

[0022] figure 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com