Interdigital back contact type solar battery and preparation method thereof

A solar cell and back-contact technology, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high cost of photolithography masks, complex structure, and difficult production, so as to reduce process steps, simple technology, The effect of reducing power generation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

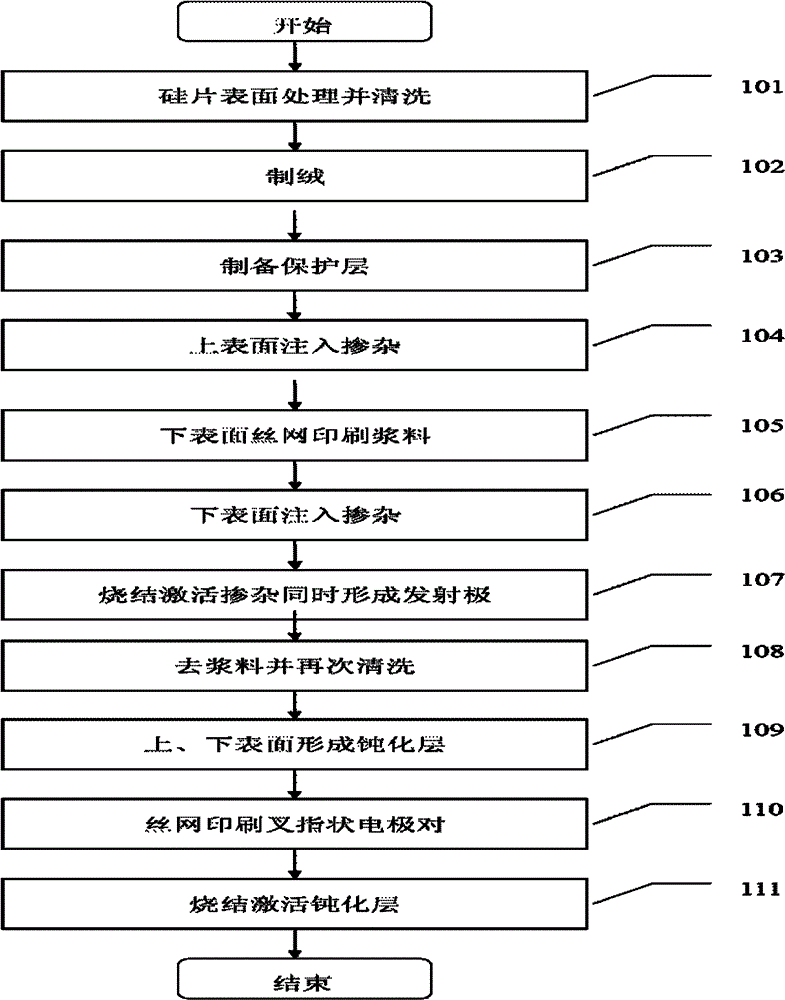

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0043] In this embodiment, the preparation method of the interdigitated back-contact solar cell of the present invention is further described in detail by taking an n-type substrate as an example.

[0044] Step: 201: select an N-type silicon wafer with a thickness of 100-500 microns, and polish it in a NaOH / KOH alkaline polishing solution with a mass fraction of 10%-50%, to remove the damaged layer on the surface;

[0045] Step 202: Perform standard cleaning on the silicon wafer, including: using No. 1 solution: NH 4 OH:H 2 o 2 :DI H 2 O=1:1:5 to remove organic matter, liquid No. 2: HCl:H 2 o 2 : DI H 2 O=1:1:6 to remove ionic impurities, No. 3 solution: DI H 2 O:HF=50:1 to remove surface oxides.

[0046] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com