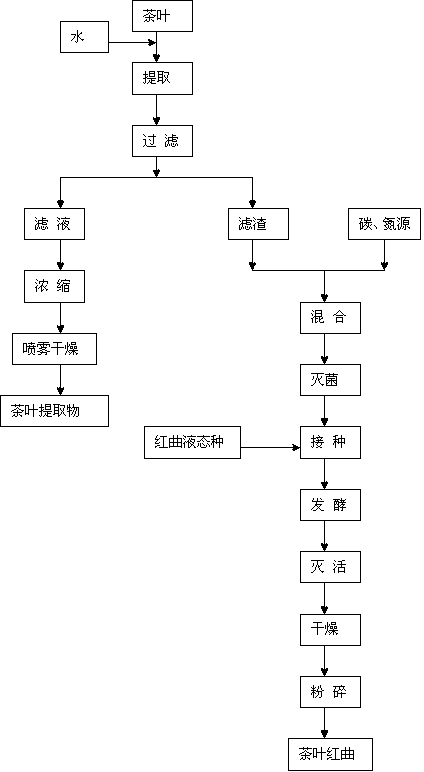

Process for utilizing tea comprehensively

A technology of tea and craftsmanship, which is applied in the field of tea comprehensive utilization technology, can solve the problems of tea leaves after extraction, achieve the effects of increasing added value, solving environmental pollution, and saving food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Liquid culture of Monasucs anka:

[0034] Liquid medium composition (weight percent): glucose 2%, sucrose 2%, rice flour 1%, soybean flour 1%, MgSO 4 0.1%, ZnSO 4 0.1%, KH 2 PO 4 0.2%, the balance is distilled water, and the pH value is natural. 500mL capacity is 250mL, and then the liquid culture is sterilized at 121°C for 20 minutes. After cooling to 40°C, inoculate Monascus spores greater than 10 8 15mL of the spore suspension of Monascus spores / mL, and cultured at 32°C and 180r / min for 72h as liquid Monascus species.

[0035] Weigh 500 grams of dry green tea, add 8 times of water, extract at 100°C for 1 hour, filter, add 6 times of water to the obtained filter residue, extract at 100°C for 30 minutes, filter, combine the filtrates, concentrate to a specific gravity of 1.15g / mL, Spray drying is carried out to obtain tea extract, and the content of tea polyphenols in the obtained tea water extract is as high as 37.8%.

[0036] Gained filter residue 932 grams,...

Embodiment 2

[0038] Liquid culture of Monasucs purpureus:

[0039] The composition of the liquid medium (weight and volume percentage): glucose 2%, sucrose 2%, rice flour 1%, soybean flour 1%, MgSO 4 0.1%, ZnSO 4 0.1%, KH 2 PO 4 0.2%, the balance is distilled water, and the pH value is natural. The volume of the 500mL triangular flask is 250mL, and then the liquid culture is sterilized at 121°C for 20 minutes. After cooling to 40°C, inoculate the purple red yeast rice spores eluted from the slope for more than 10 8 10mL of the spore suspension of Monascus spores / mL, and cultured at 32°C and 180r / min for 72h as liquid Monascus species.

[0040] Weigh 500 grams of dry green tea, add 8 times of water, extract at 80°C for 1 hour, filter, add 6 times of water to the obtained filter residue, extract at 100°C for 1 hour, filter, combine the filtrates, concentrate to a specific gravity of 1.1g / mL, Spray drying is carried out to obtain tea extract, and the content of tea polyphenols is 34.2...

Embodiment 3

[0043] Liquid culture of Monasucs ruber:

[0044] Liquid medium composition (weight percent): glucose 2%, rice flour 1%, soybean flour 1%, MgSO 4 0.1%, ZnSO 4 0.1%, KH 2 PO 4 0.2%, the balance is distilled water, and the pH value is natural. 500mL capacity is 250mL, and then the liquid culture is sterilized at 121°C for 20 minutes. After cooling to 40°C, inoculate with more than 10 red yeast spores eluted from the slant. 8 10 mL of Monascus spore suspension per mL was cultured at 32°C and 180 r / min for 72 hours as a liquid Monascus species.

[0045] Weigh 700 grams of dry green tea, add 8 times of water, extract at 100°C for 1 hour, filter, add 6 times of water to the obtained filter residue, extract at 100°C for 1 hour, filter, combine the filtrates, concentrate to a specific gravity of 1.1g / mL, Spray-drying is carried out to obtain a tea extract, and the obtained tea extract is detected to have a tea polyphenol content of 38.5%.

[0046] Gained filter residue 1212 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com