Porridge pasty piglet feed and preparation method thereof

A technology of piglet feed and paste, applied in animal feed, animal feed, application, etc., can solve the problems of inability to provide sufficient nutrition for weaned piglets, difficulty in large-scale promotion of artificial milk, inconvenient use of artificial milk, etc., to reduce diarrhea and mortality, improved gut health, and excellent feed palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Porridge Paste for Piglets

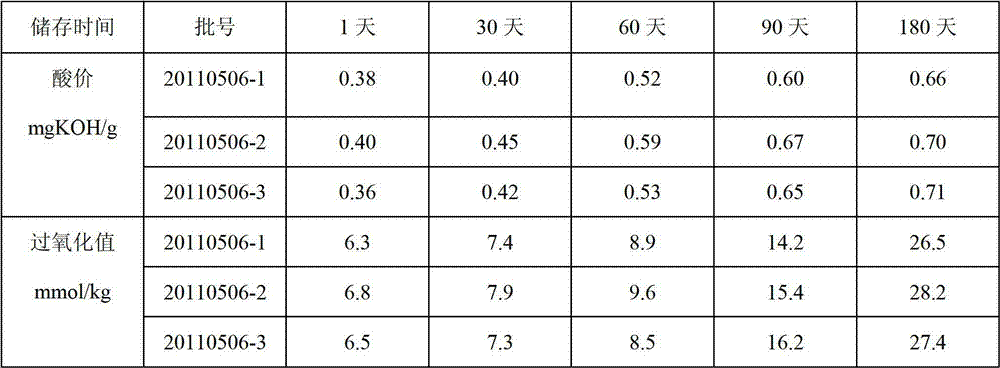

[0026] On May 6, 2011, 3 batches of porridge paste piglet feed were produced and prepared, of which formula 1 (Table 1) prepared 1 batch, batch number: 20110506-1; formula 2 (Table 2) prepared 1 batch, batch number: 20110506-2; Formula 3 (Table 3) prepares 1 batch, batch number: 20110506-3, and the production steps are as follows:

[0027] Batch number: 20110506-1 Preparation of porridge paste piglet feed:

[0028] (1) Grind the raw materials in Table 1 except water and soybean oil to a fineness of 60 meshes, weigh each raw material according to the content of the formula, mix pig plasma protein powder, milk powder, fish meal, multivitamin, calcium hydrogen phosphate and compound Minerals are mixed evenly to obtain a mixture;

[0029] (2) Heat the water to 90°C in a hot stirring tank, then add compound acidified preservatives to the water, heat and sterilize for 30 minutes, then add rice flour, sucrose and whey powder and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com