Collagen basal bone cartilage three-layer compound and preparation method thereof

A composite, osteochondral technology, applied in medical science, prosthesis, etc., to prevent splitting between layers and improve interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Extraction of Water-Soluble Type I Collagen

[0030] ①Take off the tendons from the fresh pork legs of two-month-old healthy white pigs, remove the fascia and fat, cut them into 120g tendon slices, soak them in 500mL of ethanol solution with a volume concentration of 75%, and overnight at 4°C; ②The tendons from step ① Rinse 95g slices with distilled water 5 times, add 0.5mol / L acetic acid aqueous solution 1800mL, adjust pH to 1 with 6M sodium hydroxide aqueous solution, add pepsin (Sigma-ALDRICH, P7000-25G, 1:10000, 601U / mg) 9g, placed at 4°C for 3 days to obtain 1800mL collagen sol solution; ③Centrifuge the collagen sol solution obtained in step ② at 4°C and 4000rpm for 25 minutes, discard the upper fat layer, and dilute the precipitate a with 0.5mol / L acetic acid aqueous solution for 3 double the volume, filter it with 4 layers of gauze in an ultra-clean bench, mix the filtrate with 0.9 mol / L NaCl aqueous solution at a volume ratio of 1:10, shake intermitten...

Embodiment 2

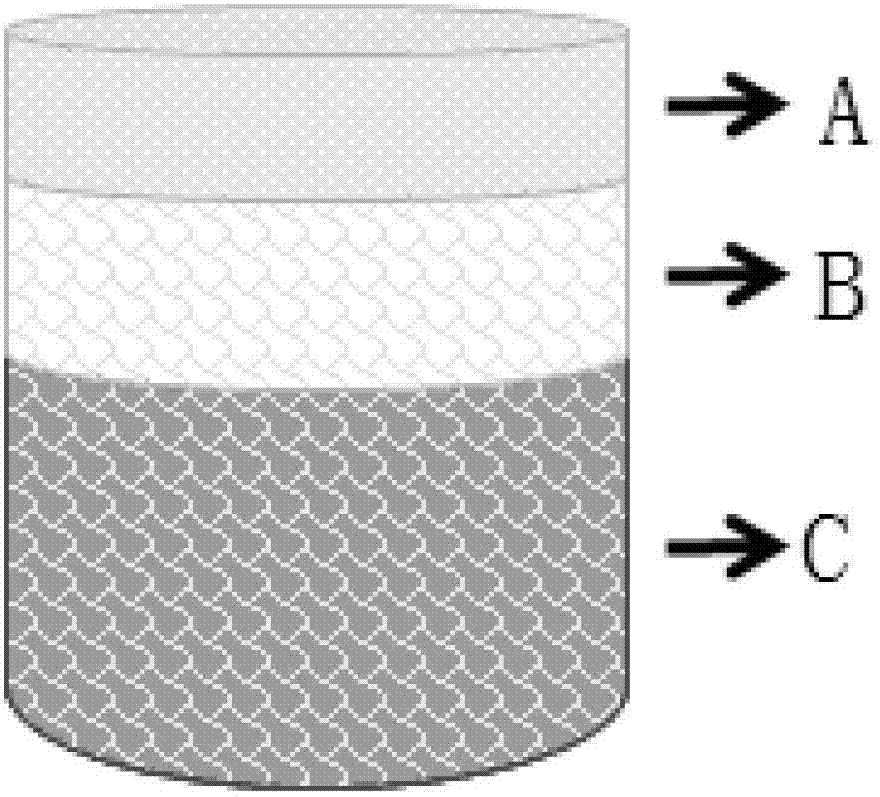

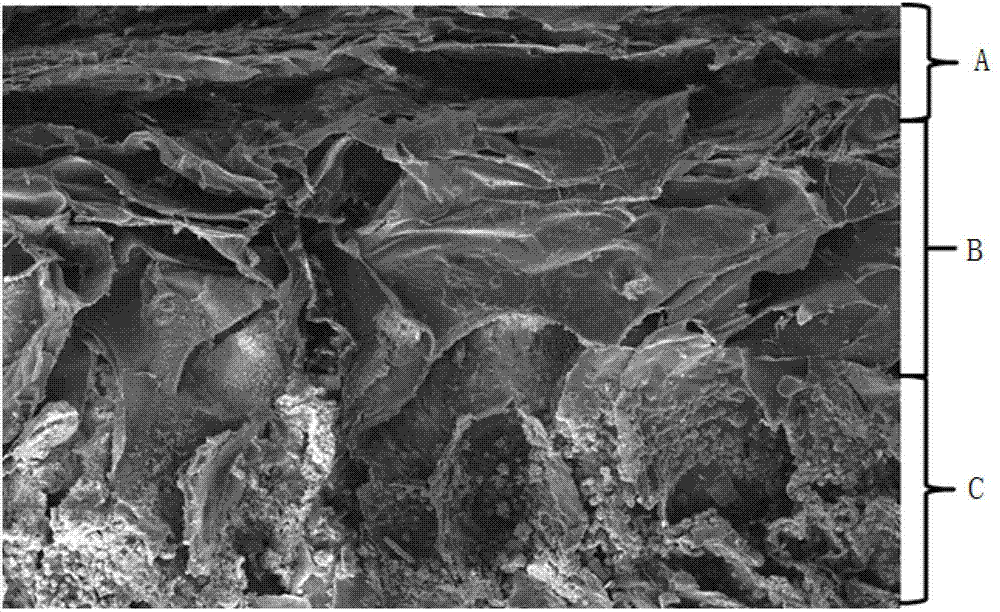

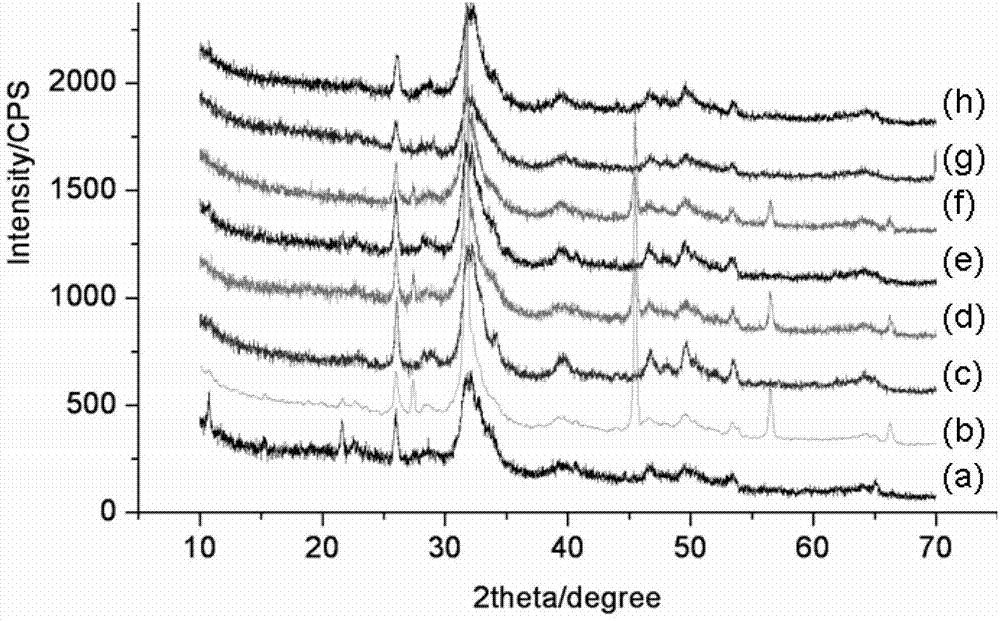

[0032] (1) Dissolve the water-soluble type I collagen extracted by the method in Example 1 in deionized water to prepare 10 mL of 10 mg / mL collagen aqueous solution, 5 mL of 10 mg / mL collagen aqueous solution, and 5 mL of 35 mg / mL collagen aqueous solution; Dissolve dipotassium hydrogen phosphate in 10 mL of the above-mentioned 10 mg / mL collagen aqueous solution (collagen quality is 100 mg) to prepare a collagen-phosphate mixed solution; take ten polytetrafluoroethylene cylindrical molds with a depth of 8 mm and a diameter of 8 mm, each The molds were first injected with a 5mm height of collagen-phosphate mixed solution, frozen at -20°C for 24 hours, and then added with a 2mm height of 10mg / mL collagen aqueous solution, after standing at 0°C for 1min, then frozen at -20°C for 24 hours After that, inject 35mg / mL collagen aqueous solution at a height of 1mm, let stand at 0°C for 1min, freeze at -20°C for 24 hours, remove the mold, and obtain dense collagen-porous collagen-collage...

Embodiment 3

[0036] (1) Dissolve the water-soluble type I collagen extracted by the method in Example 1 in deionized water to prepare 10 mL of 20 mg / mL collagen aqueous solution, 5 mL of 15 mg / mL collagen aqueous solution, and 5 mL of 40 mg / mL collagen aqueous solution; Dipotassium hydrogen dipotassium was dissolved in 10 mL of the above 20 mg / mL collagen aqueous solution to prepare a collagen-phosphate mixed solution; take ten polytetrafluoroethylene cylindrical molds with a depth of 8 mm and a diameter of 8 mm, and each mold was first injected with 4 mm high Collagen-phosphate mixed solution, freeze at -50°C for 16 hours, then inject 15mg / mL collagen aqueous solution at a height of 3mm, let stand at 4°C for 5min, freeze at -50°C for 16 hours, and then inject at a height of 1mm 40mg / mL collagen aqueous solution, after standing at 4°C for 5min, freeze at -50°C for 16 hours, remove the mold, and obtain dense collagen-porous collagen-collagen water-soluble phosphate complex;

[0037] (2) Dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com