Method for preparing biological oil and biological char by thermal cracking and liquefying bamboo wood

A technology of biochar and pyrolysis, which is applied in the preparation of liquid hydrocarbon mixture, biofuel, petroleum industry, etc., can solve the problems that have not been reported, and achieve the effects of low operating cost, improved utilization of bamboo resources, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

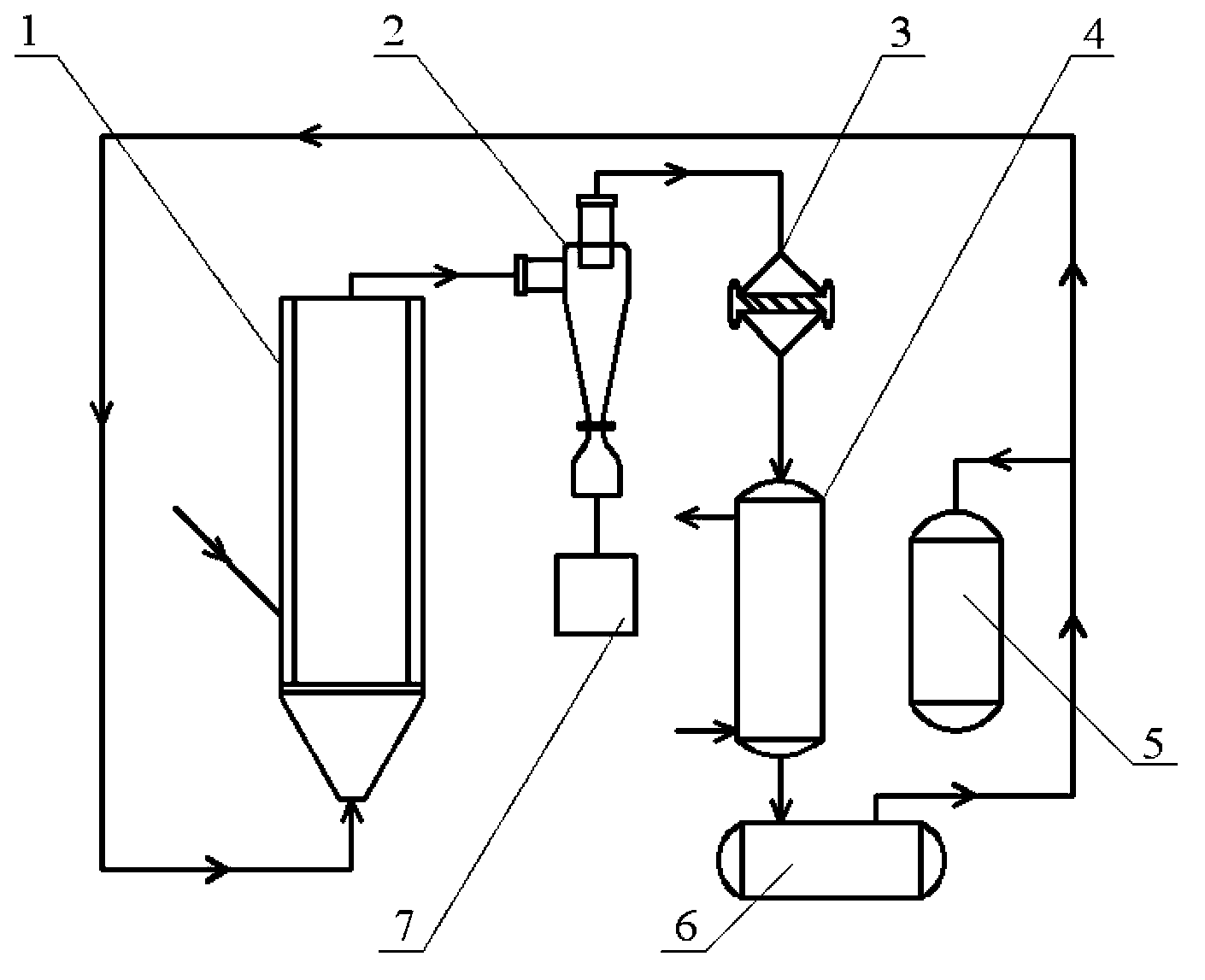

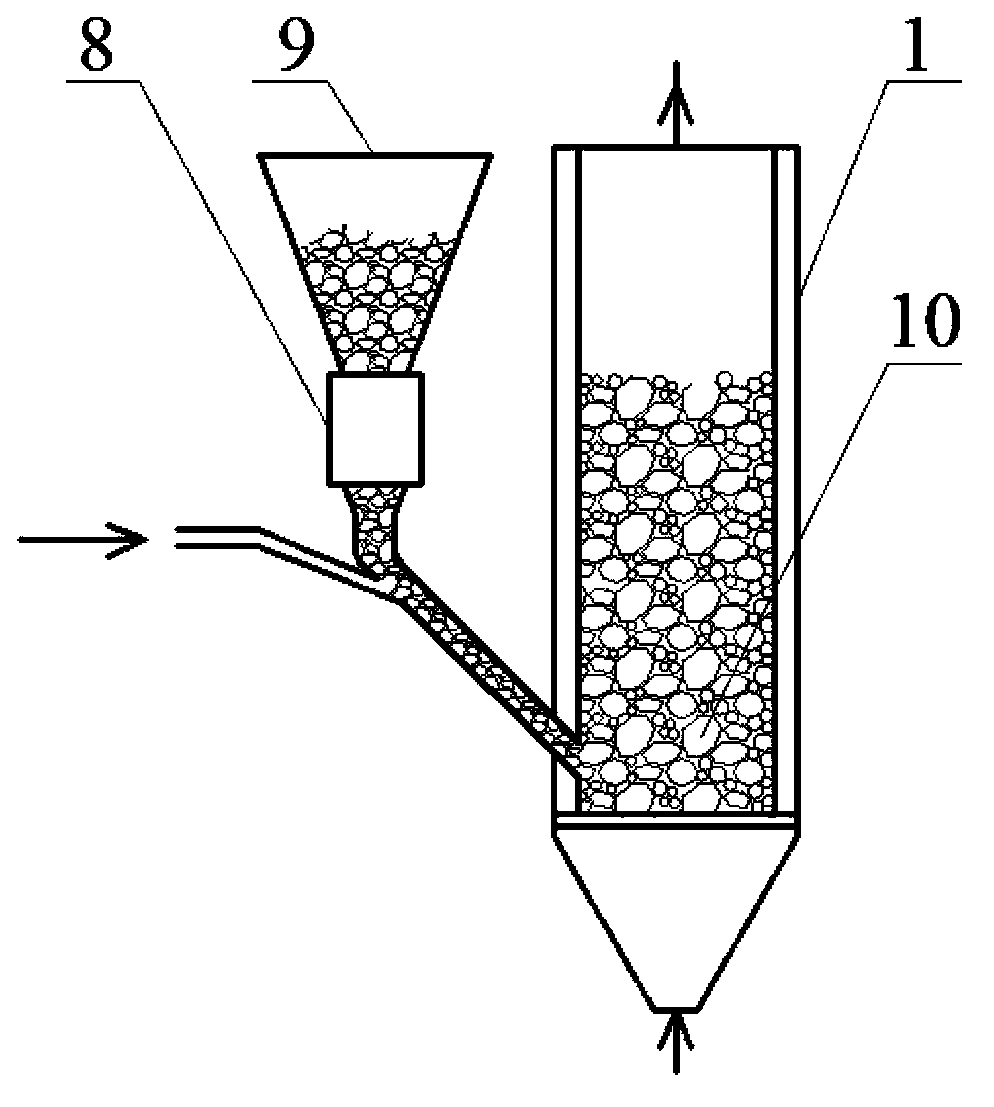

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing bio-oil and bio-char by pyrolysis and liquefaction of bamboo, the steps of the method are as follows:

[0054] Step 1. Raw material pretreatment

[0055] The moso bamboo processing residues are crushed to obtain bamboo particles with a particle size of less than 2 mm, and then undergo deashing treatment. The deashing treatment process steps are: deionized water washing ①-acid washing-deionized water washing ②; among them, deionized water washing ① The process is to immerse the bamboo granules in deionized water, the weight ratio of bamboo granules to deionized water is 1:20, the treatment temperature is 50°C, and the treatment time is 15 minutes; during the pickling process, the bamboo granules washed with deionized water are immersed in hydrochloric acid solution In the process, the concentration of hydrochloric acid solution is 3.5mol / L, the treatment temperature is 50°C, the treatment time is 20min, and the weight ratio of bamboo particles to h...

Embodiment 2

[0077] A method for preparing bio-oil and bio-char by pyrolysis and liquefaction of bamboo, the steps of the method are as follows:

[0078] Step 1. Raw material pretreatment

[0079] The moso bamboo processing residues are crushed to obtain bamboo particles with a particle size of less than 2 mm, and then undergo deashing treatment. The deashing treatment process steps are: deionized water washing ①-acid washing-deionized water washing ②; among them, deionized water washing ① The process is to immerse the bamboo granules in deionized water, the weight ratio of bamboo granules to deionized water is 1:20, the treatment temperature is 50°C, and the treatment time is 15 minutes; during the pickling process, the bamboo granules washed with deionized water are immersed in hydrochloric acid solution In the process, the concentration of hydrochloric acid solution is 3.5mol / L, the treatment temperature is 60°C, the treatment time is 20min, and the weight ratio of bamboo particles to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com