Complete processing unit for sludge drying

A complete set of treatment and sludge drying technology, applied in the direction of dehydration/drying/thickened sludge treatment, incinerator, combustion method, etc., can solve the problems of poor quality of dry materials, high energy consumption, low efficiency, etc., and achieve good results Environmental protection effect, low energy consumption, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

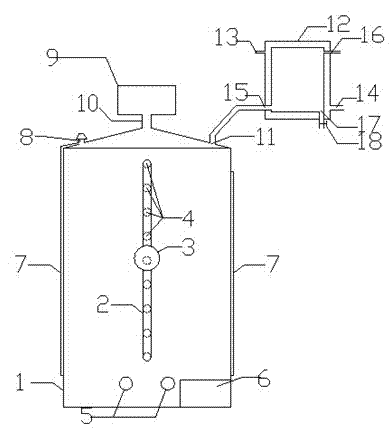

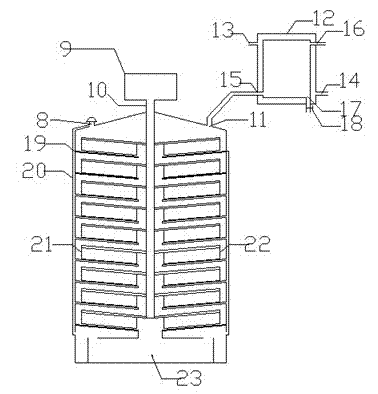

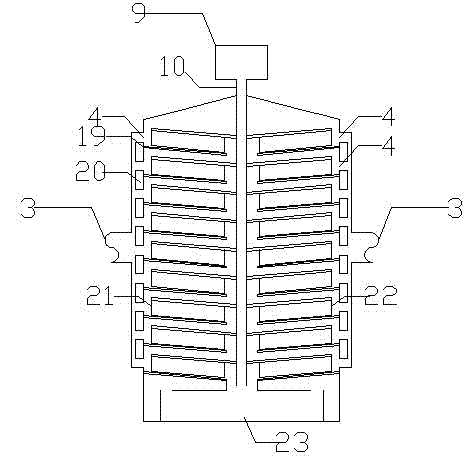

[0021] Embodiment 1: as Figure 1-4 As shown, a complete set of sludge drying treatment device includes a scraper type sludge dryer 1, a distributed feeding device 2, an exhaust gas cooling tower 12, and a sludge incineration device 23; the upper end of the scraper type sludge dryer 1 and the exhaust gas The cooling tower 12 is connected, the lower end is connected with the sludge incineration equipment 23, and the distributed feeding device 2 is installed on the scraper type sludge dryer 1.

[0022] The scraper type sludge dryer 1 includes a safety valve 8, a motor 9, a circular plate 19, a cylinder 20, a positive scraper 21, and a reverse scraper 22; the cylinder 20 of the scraper type sludge dryer 1 is equipped with a rotating shaft 10 , the motor 9 is installed above the rotating shaft 10, the safety valve 8 is arranged at the upper left side of the cylinder 20 of the scraper type sludge dryer 1, the positive scraper 21 and the reverse scraper 22 are arranged on the rotati...

Embodiment 2

[0025] Embodiment 2: as Figure 1-4 As shown, a complete set of sludge drying treatment device includes a scraper type sludge dryer 1, a distributed feeding device 2, an exhaust gas cooling tower 12, and a sludge incineration device 23; the upper end of the scraper type sludge dryer 1 and the exhaust gas The cooling tower 12 is connected, the lower end is connected with the sludge incineration equipment 23, and the distributed feeding device 2 is installed on the scraper type sludge dryer 1.

[0026] The scraper type sludge dryer 1 includes a safety valve 8, a motor 9, a circular plate 19, a cylinder 20, a positive scraper 21, and a reverse scraper 22; the cylinder 20 of the scraper type sludge dryer 1 is equipped with a rotating shaft 10 , the motor 9 is installed above the rotating shaft 10, the safety valve 8 is arranged on the upper right side of the cylinder 20 of the scraper type sludge dryer 1, the positive scraper 21 and the reverse scraper 22 are arranged on the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com