Conductive polyurethane superfine fiber suede leather and preparing method thereof

A technology of ultra-fine fibers and manufacturing methods, applied in fiber processing, textiles and papermaking, etc., can solve the problems of low light transmittance, long reaction time, short service life, etc., achieve huge market prospects, excellent conductive effect, improve The effect of color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The superfine fiber synthetic leather base cloth is sequentially subjected to peeling treatment, buffing treatment and dyeing treatment to obtain superfine fiber suede leather.

[0028] (2) Dry the superfine fiber suede leather treated in (1) at a temperature of 80°C for 30 minutes, and then immerse it in a conductive treatment solution for 5 seconds at a bath ratio of 1:1, then take it out, and dry it at a temperature of 80°C Drying in medium for 30 minutes can obtain a kind of conductive polyurethane superfine fiber suede leather.

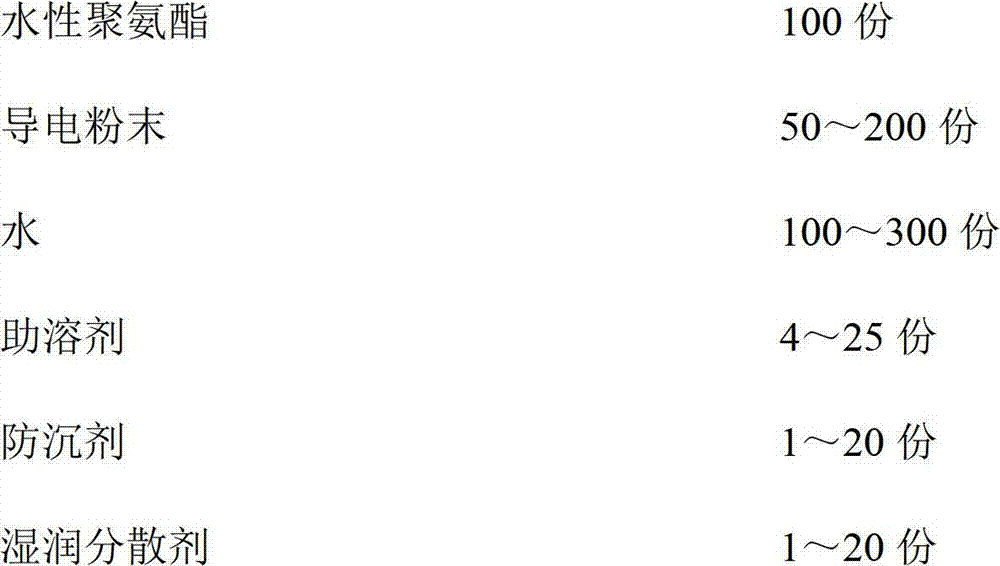

[0029] The composition of the conductive treatment liquid is:

[0030] 1. Waterborne polyurethane Impranil LP RSC 1380: 100 parts

[0031] 2. Conductive zinc oxide powder: 50 parts

[0032] 3. Deionized water: 100 parts

[0033] 4. Cosolvent (dimethyl sulfoxide): 4 parts

[0034] 5. Thixatrol p200x anti-sedimentation agent: 1 part

[0035] 6. Wetting and dispersing agent (polyether modified polydimethylsiloxane): 1 part

[0036] ...

Embodiment 2

[0039] (1) The superfine fiber synthetic leather base cloth is sequentially subjected to peeling treatment, buffing treatment and dyeing treatment to obtain superfine fiber suede leather.

[0040] (2) Dry the superfine fiber suede leather treated in (1) at a temperature of 120°C for 15 minutes, then immerse it in the conductive treatment solution for 250 seconds, the bath ratio is: 1:10, then take it out, and heat it at 120°C Dry at a certain temperature for 15 minutes to obtain a conductive polyurethane superfine fiber suede leather.

[0041] The composition of the conductive treatment liquid is:

[0042] 1. Waterborne polyurethane Impranil LP RSC 1380: 100 parts

[0043] 2. Conductive indium oxide powder: 120 parts

[0044] 3. Deionized water: 150 parts

[0045] 4. Co-solvent (propylene glycol methyl ether acetate): 10 parts

[0046] 5. Thixatrol p200x anti-sedimentation agent: 10 parts

[0047] 6. Wetting and dispersing agent (polyether modified trisiloxane): 10 parts ...

Embodiment 3

[0050] (1) The superfine fiber synthetic leather base cloth is sequentially subjected to peeling treatment, buffing treatment and dyeing treatment to obtain superfine fiber suede leather.

[0051] (2) Dry the microfiber suede leather treated in (1) at a temperature of 140°C for 5 minutes, then immerse it in the conductive treatment solution for 500 seconds, the bath ratio is: 1:20, then take it out, and heat it at 140°C Drying at a certain temperature for 5 minutes can obtain a conductive polyurethane superfine fiber suede leather.

[0052] The composition of the conductive treatment liquid is:

[0053] 1. Waterborne polyurethane Impranil LP RSC 1380: 100 parts

[0054] 2. Conductive tin dioxide powder: 200 parts

[0055] 3. Deionized water: 300 parts

[0056] 4. Cosolvent (propylene glycol methyl ether acetate): 25 parts

[0057] 5. Thixatrol p200x anti-sedimentation agent: 20 parts

[0058] 6. Wetting and dispersing agent (polyether modified polydimethylsiloxane): 20 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com