Plastic coated paper base with antistatic bottom layers on two sides

An anti-static, bottom-layer technology, applied in optics, instruments, photosensitive materials, etc., can solve the problems of increased surface resistance of paper base, static electricity, product scrapping, etc., and achieve the effect of avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

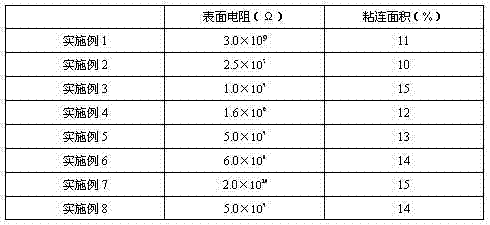

Examples

Embodiment 1

[0023] Anti-static base formula composition:

[0024] 100g deionized water,

[0025] Photographic gelatin 1g,

[0026] Potassium nitrate 0.5g,

[0027] Aluminum oxide (2.5μm) 0.1g,

[0028] According to the formula requirements, add deionized water and photographic gelatin into the container, after the gelatin is fully soaked, heat to dissolve it completely, then add aluminum oxide and potassium nitrate in turn under stirring, and stir evenly to obtain the antistatic bottom coating liquid, stand-by.

[0029] One side of the photographic base paper is subjected to high-voltage corona treatment, and then coated with a polymer layer, and after cold roll pressing and cooling, the other side of the photographic base paper is subjected to high-voltage corona treatment, coated with a polymer layer, and cold roll pressing Cooling; performing high-voltage corona treatment on the above-mentioned polymer layer, adopting the relay coating method, coating the above-mentioned antistatic...

Embodiment 2

[0031] Anti-static base formula composition:

[0032] 100g deionized water,

[0033] Photographic gelatin 0.5g,

[0035] Silica (4.3μm) 0.5g,

[0036] According to the formula requirements, add deionized water and photographic gelatin into the container, after the gelatin is fully soaked, heat to dissolve it completely, then add aluminum oxide and potassium nitrate in turn under stirring, and stir evenly to obtain the antistatic bottom coating liquid, stand-by.

[0037] One side of the photographic base paper is subjected to high-voltage corona treatment, and then coated with a polymer layer, and after cold roll pressing and cooling, the other side of the photographic base paper is subjected to high-voltage corona treatment, coated with a polymer layer, and cold roll pressing Cooling; performing high-voltage corona treatment on the above-mentioned polymer layer, adopting the relay coating method, coating the above-mentioned antistatic bottom...

Embodiment 3

[0039] Anti-static base formula composition:

[0040] 100g deionized water,

[0041] Photographic gelatin 1.5g,

[0042] Sodium polystyrene sulfonate 0.9g,

[0043] Titanium dioxide (0.01μm) 0.1g,

[0044] According to the formula requirements, add deionized water and photographic gelatin into the container, after the gelatin is fully soaked, heat to dissolve it completely, then add aluminum oxide and potassium nitrate in turn under stirring, and stir evenly to obtain the antistatic bottom coating liquid, stand-by.

[0045] One side of the photographic base paper is subjected to high-voltage corona treatment, and then coated with a polymer layer, and after cold roll pressing and cooling, the other side of the photographic base paper is subjected to high-voltage corona treatment, coated with a polymer layer, and cold roll pressing Cooling; performing high-voltage corona treatment on the above-mentioned polymer layer, adopting the relay coating method, coating the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com