A kind of high-performance pe film and its preparation method and application

A high-performance, thin-film technology, applied in the field of plastic films, can solve the problems of low printing efficiency, heat resistance, poor aging resistance, etc., achieve fast drying speed, maintain smooth performance, and improve anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

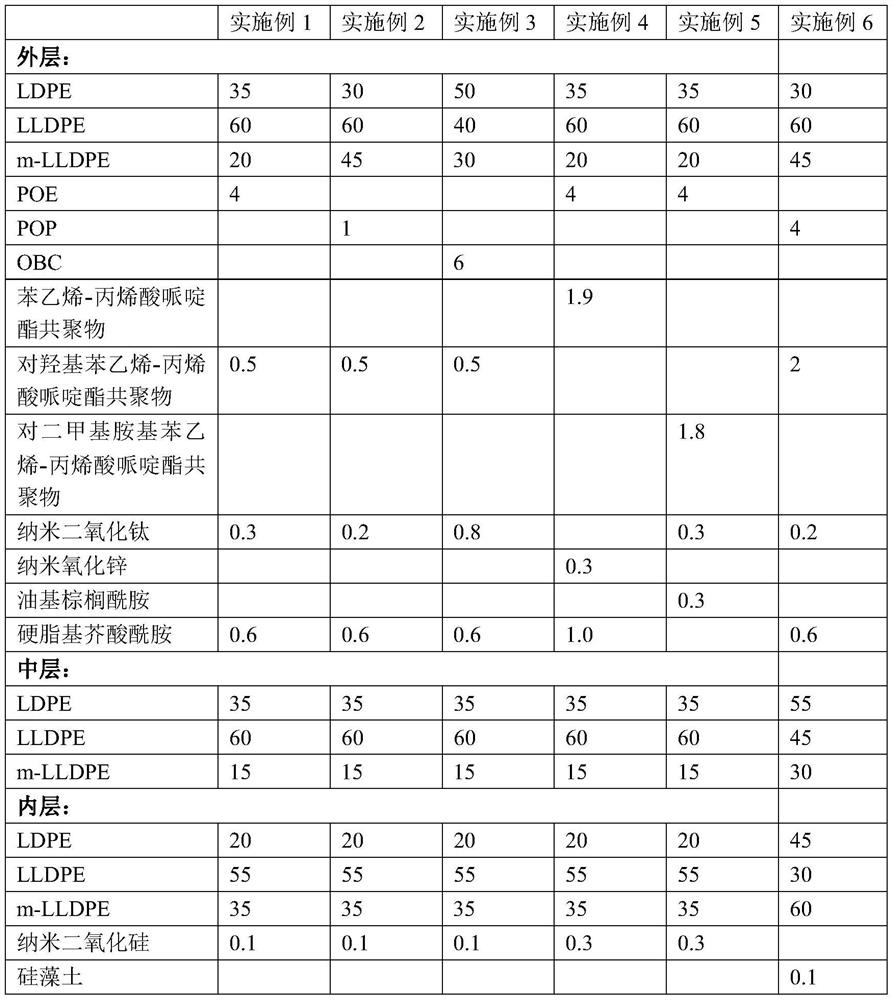

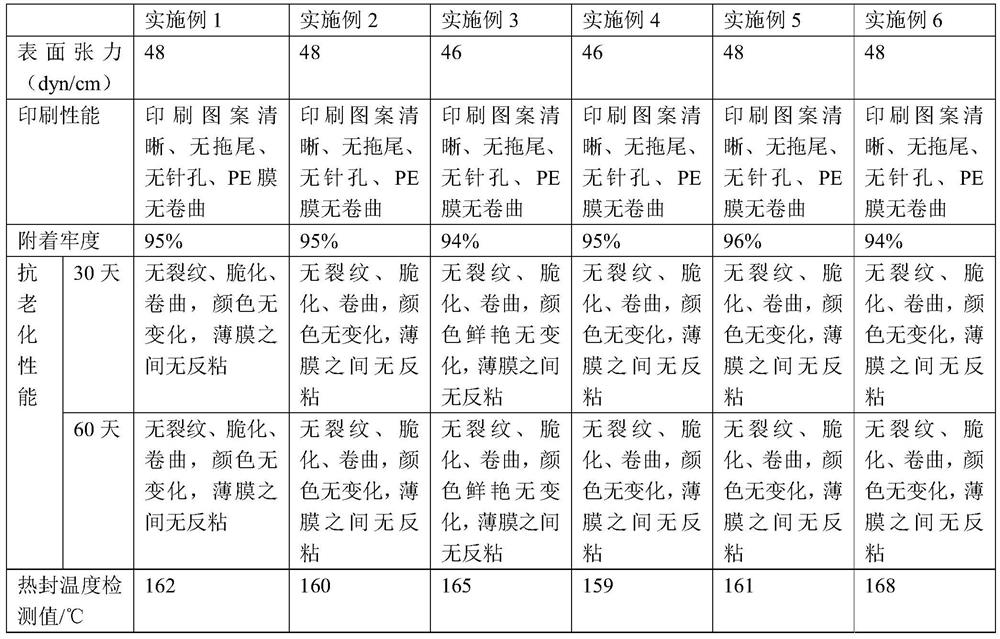

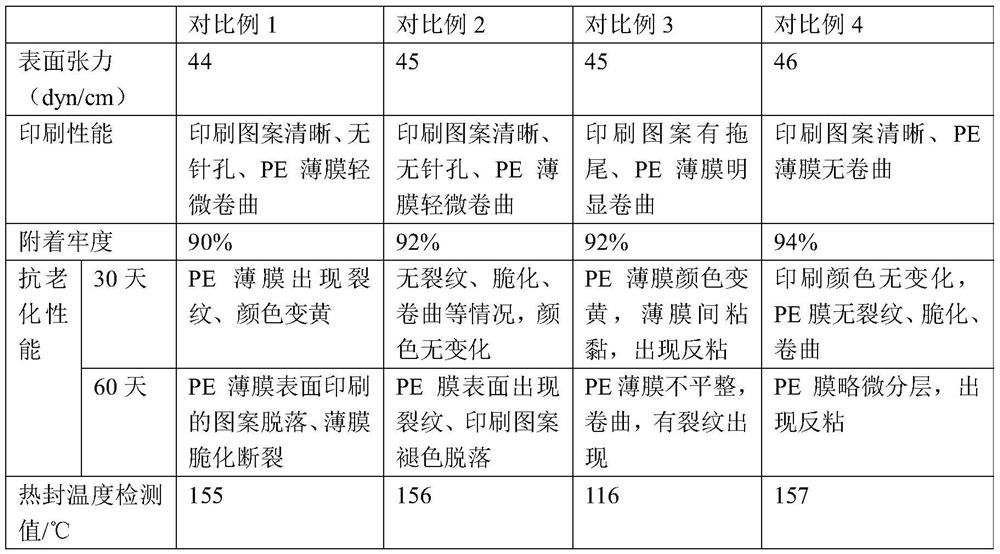

[0062] Embodiments 1 to 6 provide a PE film, the raw material composition of which is shown in Table 1.

[0063] Table 1 Raw material composition of outer layer, middle layer and inner layer of PE film (parts by weight)

[0064]

[0065] The preparation method of the PE film of embodiment 1~6 is:

[0066] S1. Mix the raw materials of the outer layer, the middle layer and the inner layer of the PE film according to the proportions, add them to the extruder respectively, and then extrude and granulate to obtain the outer layer pellets, the middle layer pellets and the inner layer pellets;

[0067] S2. The outer layer pellets, the middle layer pellets, and the inner layer pellets are respectively added to the three-layer co-extrusion blown film machine, melt-extruded through the three-layer co-extrusion process, and subjected to inflation and traction, cooling, and corona treatment. , film winding to prepare the high-performance PE film;

[0068] The conditions of corona tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com