Gas-direct-contact-type ice slurry generator

A generator, contact technology, applied in the direction of ice making, ice making, heating methods, etc., can solve the problems of ice making solution leakage, increased maintenance cost, easy occurrence of ice blockage, etc., to increase movement resistance and save investment costs. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

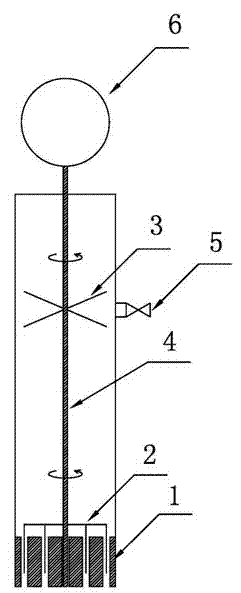

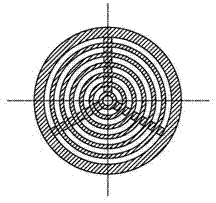

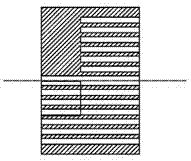

[0016] As shown in the figure, the gas direct contact ice slurry generator includes a concentric ring nozzle 1, a deicer 2, an agitator 3, a transmission shaft 4, an ice outlet 5, and a drive motor 6; the lower end of the generator body is provided with a concentric ring nozzle 1. There is a drive shaft 4 in the center of the generator body, an agitator 3 is installed on the drive shaft 4, a drive motor 6 is installed above the generator body, an ice outlet 5 is provided on the side wall of the upper part of the generator body, and the upper end of the drive shaft 4 is connected to The driving motor 6 is connected, the lower end of the transmission shaft 4 is connected with the deicer 2, the deicer 2 includes a bracket 7 and a deicing blade 8, the lower surface of the bracket 7 is vertically provided with a deicing blade 8, and the bracket 7 is provided with 1 to 3 arms , the lower end of the deicing blade 8 extends into the annular channel of the concentric ring nozzle 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com