Manganese-aluminum containing anode material and preparation method thereof, as well as air cell prepared by using anode material

A manganese-aluminum alloy and air battery technology, which is applied to fuel cell type half cells and primary cell type half cells, battery electrodes, circuits, etc. Mitigation of harmful effects, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

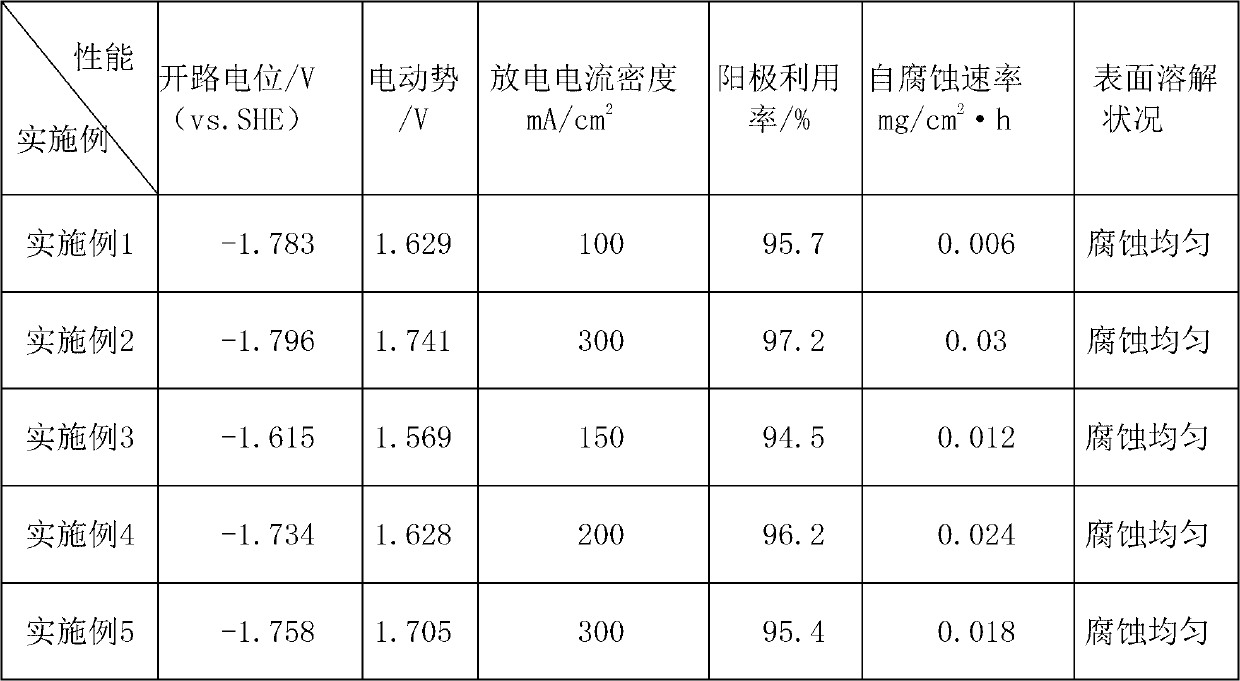

Examples

Embodiment 1

[0016] The cathode of the air battery is composed of a catalytic layer, a nickel mesh conductive framework and a waterproof and breathable layer, in which the catalytic layer is γ-MnO 2 1. Activated carbon and polytetrafluoroethylene are mixed and rolled at a weight ratio of 0.5:2:1 to make a 0.5mm thick film. The waterproof layer is made of polytetrafluoroethylene and acetylene black at a weight ratio of 1:1 to make a 0.3mm thick film. Finally, the catalytic layer, nickel mesh and waterproof and breathable layer are laminated to form a 0.3mm thick air cathode. The electrolyte is 4M NaCl.

[0017] The weight percentage of each component of the manganese aluminum alloy anode material is: Mg: 0.05%; Sn: 1%; Ga: 2.5%; Mn: 0.1%; the rest is Al.

[0018] Under the protection of argon, the aluminum ingots were melted in the crucible of the ZGJL0.01-40-4 induction melting furnace at a temperature of 700 °C, and then magnesium ingots, aluminum-manganese intermediate alloys (90%Al-10%...

Embodiment 2

[0020] The cathode of the air battery is composed of a catalytic layer, a nickel mesh conductive framework and a waterproof and breathable layer, in which the catalytic layer is γ-MnO 2 1. Activated carbon and polytetrafluoroethylene are mixed and rolled at a weight ratio of 2:4:3 to make a 0.3mm thick film. The waterproof layer is made of polytetrafluoroethylene and acetylene black at a weight ratio of 1:1 to make a 0.35mm thick film. Finally, the catalytic layer, nickel mesh and waterproof and breathable layer are laminated to form a 0.5mm thick air cathode. The electrolyte is 2M NaCl.

[0021] The weight percentage of each component of the manganese aluminum alloy anode material is: Mg: 2.5%; Sn: 0.05%; Ga: 0.05%; Mn: 1%; the rest is Al.

[0022] Under the protection of argon, the aluminum ingots were melted in the crucible of the ZGJL0.01-40-4 induction melting furnace at a temperature of 680 °C, and then magnesium ingots, aluminum-manganese intermediate alloys (90%Al-10%Mn...

Embodiment 3

[0024] The cathode of the air battery is composed of a catalytic layer, a nickel mesh conductive framework and a waterproof and breathable layer, in which the catalytic layer is γ-MnO 2 , Activated carbon and polytetrafluoroethylene are mixed and rolled at a weight ratio of 1:3:2 to make a 0.4mm thick film, and the waterproof layer is made of polytetrafluoroethylene and acetylene black mixed and rolled at a weight ratio of 1:1 to make a 0.5mm thick film Finally, the catalytic layer, nickel mesh and waterproof and breathable layer are laminated to form a 0.35mm thick air cathode. The electrolyte is 1M NaCl.

[0025] The weight percentage of each component of the manganese aluminum alloy anode material is: Mg: 2%; Sn: 1.5%; Ga: 1%; Mn: 0.5%; the rest is Al.

[0026] Under the protection of argon, the aluminum ingots were melted in the crucible of the ZGJL0.01-40-4 induction melting furnace at a temperature of 690 °C, and then magnesium ingots, aluminum-manganese intermediate al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com