Method for producing biologic protein feed by using solid-state fermentation fiber dreg

A technology of biological protein feed and solid-state fermentation, applied in animal feed, animal feed, application and other directions, can solve the problems of low added value of products and low degree of degradable utilization of corn husk residue, and achieve the goal of increasing added value and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

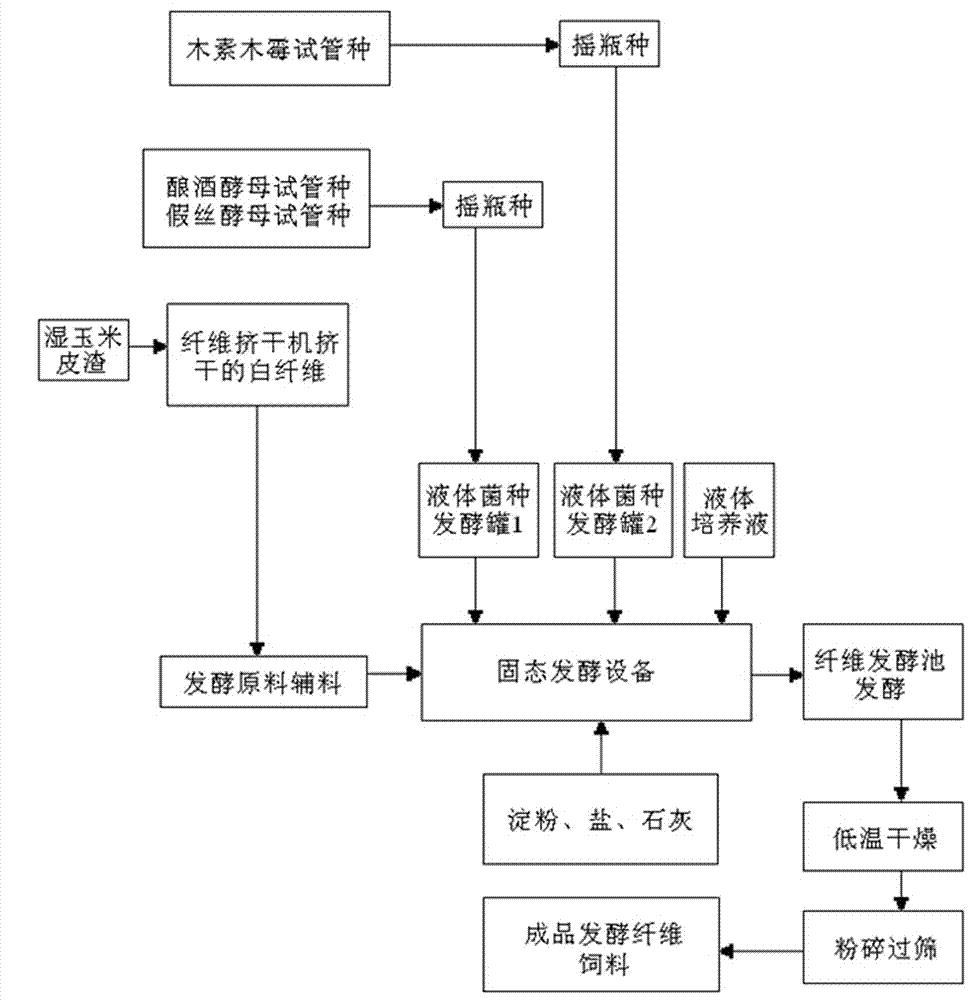

Method used

Image

Examples

Embodiment 1

[0041] Inoculate Trichoderma lignin into a large test tube containing 5ml of wort after activation, culture on a shaker at 28°C with a rotation speed of 220r / min for 20 hours, and then inoculate 5% of the inoculum into a Erlenmeyer flask containing 500ml of wort , cultured on a shaking table at 28°C for 20h, inserted into the sterilized liquid strain fermenter and fermented at 28°C for 16h to obtain the first liquid strain; activated Candida utilis and Saccharomyces cerevisiae were inoculated into 5ml of wort together In a large test tube, culture on a shaker at 28°C with a rotation speed of 220r / min for 20h, then inoculate 5% of the inoculum into a conical flask containing 500ml of wort, cultivate on a shaker at 28°C for 20h, and insert it into another sterilized The liquid strain fermenter was fermented at 30° C. for 16 hours to obtain the second liquid strain. Get the corn soaking water produced in the soaking process in the wet corn starch production process, add 5g corn f...

Embodiment 2

[0047] Inoculate Trichoderma lignin into a large test tube containing 5ml of wort after activation, culture on a shaker at 28°C with a rotation speed of 220r / min for 20 hours, and then inoculate 5% of the inoculum into a Erlenmeyer flask containing 500ml of wort , cultured on a shaker at 28°C for 20h, inserted into the sterilized liquid strain fermenter and fermented at 30°C for 16h to obtain the first liquid strain; activated Candida utilis and Saccharomyces cerevisiae were inoculated into 5ml of wort together In a large test tube, culture on a shaker at 28°C with a rotation speed of 220r / min for 20h, then inoculate 5% of the inoculum into a conical flask containing 500ml of wort, cultivate on a shaker at 28°C for 20h, and insert it into another sterilized Ferment the liquid strain fermenter at 29°C for 16 hours to obtain the second liquid strain; take the corn soaking water produced in the soaking process in the wet corn starch production process, add 7.5g corn flour and 1.5g...

Embodiment 3

[0054] Inoculate Trichoderma lignin into a large test tube containing 5ml of wort after activation, culture on a shaker at 28°C with a rotation speed of 220r / min for 20 hours, and then inoculate 5% of the inoculum into a Erlenmeyer flask containing 500ml of wort , cultured on a shaker at 28°C for 20h, inserted into the sterilized liquid strain fermenter and fermented at 29°C for 16h to obtain the first liquid strain; activated Candida utilis and Saccharomyces cerevisiae were inoculated into 5ml of wort together In a large test tube, culture on a shaker at 28°C with a rotation speed of 220r / min for 20h, then inoculate 5% of the inoculum into a conical flask containing 500ml of wort, cultivate on a shaker at 28°C for 20h, and insert it into another sterilized The liquid strain fermentation tank was fermented at 29°C for 16 hours to obtain the second liquid strain; take the corn soaking water produced in the soaking process in the wet corn starch production process, add 6.5g corn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com