Preparation method of white jade glass tableware

A glass and tableware technology, which is applied in the field of preparation of white jade crystal porcelain glass tableware, can solve problems such as fluoride pollution and dim prospects, and achieve the effects of resource saving, practicality, beauty, durability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

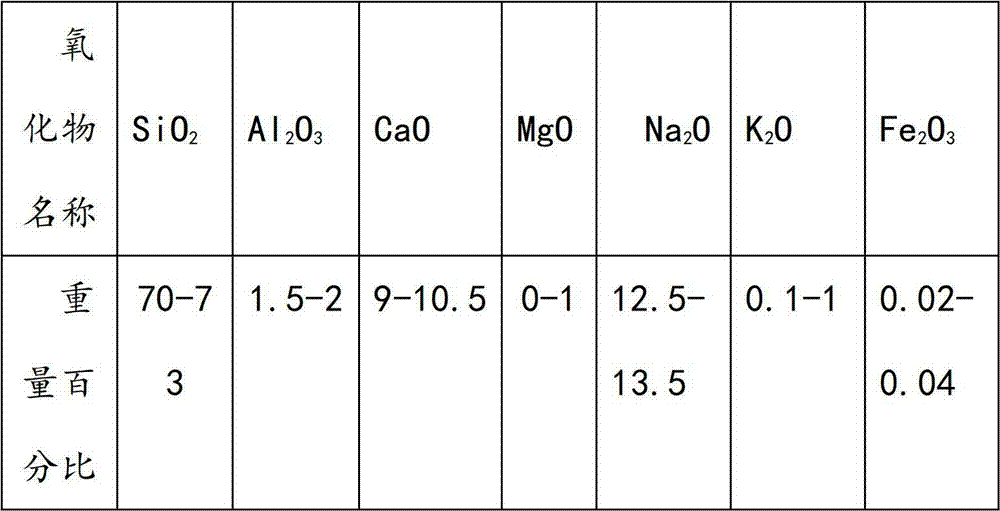

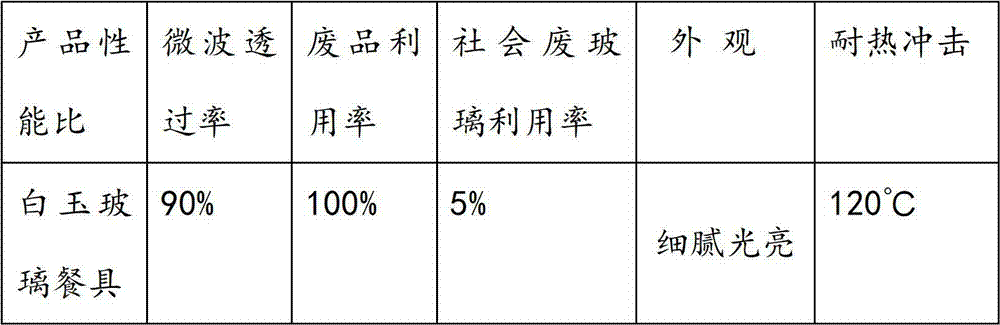

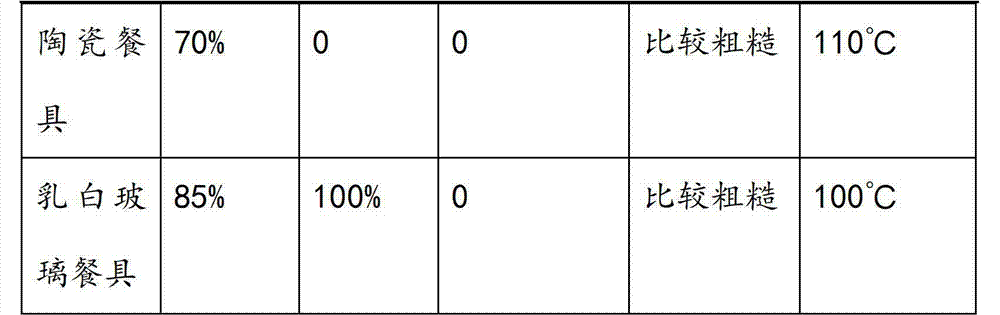

Method used

Image

Examples

Embodiment 1

[0069] Take 66 parts of quartz sand, 8 parts of waste glass, 17 parts of borax pentahydrate, 14 parts of soda ash, 12 parts of ammonium dihydrogen phosphate, 9 parts of calcium carbonate, 4 parts of potassium carbonate, 1.3 parts of zinc oxide, 3 parts of aluminum oxide powder, carbonic acid Put 2.2 parts of barium and 0.06 parts of cerium oxide into the mixer for stirring, stop when the uniformity is greater than 95%, add a small amount of water as needed, and the water content is 3-4% of the batch.

[0070] Put the evenly mixed raw materials into the furnace to melt, and the temperature of the furnace is controlled at about 1520°C, so that the material is melted into a liquid without bubbles and stones, and then cooled to 1300°C; when the raw material temperature is 1100°C, it is made by a centrifugal molding machine The dinner plate is heated and polished with fire after molding;

[0071] Put the polished molded product into the annealing furnace for annealing: the annealin...

Embodiment 2

[0074] Take 64 parts of quartz sand, 8 parts of waste glass, 19 parts of borax pentahydrate, 10 parts of soda ash, 9 parts of ammonium dihydrogen phosphate, 6 parts of calcium carbonate, 2 parts of potassium carbonate, 1.5 parts of zinc oxide, 1 part of aluminum oxide powder, Put 2.2 parts of barium and 0.06 parts of cerium oxide into the mixer for stirring, stop when the uniformity is greater than 95%, add a small amount of water as needed, and the water content is 3-4% of the batch. Put the uniformly mixed raw materials into the furnace to melt, and the temperature of the furnace is controlled at about 1510°C, so that the material is melted into a liquid without bubbles and stones, and then cooled to 1300°C; when the raw material temperature is 980°C, it is made by a centrifugal molding machine The dinner plate is heated and polished with fire after molding;

[0075] Put the polished molded product into the annealing furnace for annealing: the annealing furnace includes an 1...

Embodiment 3

[0078] Take 65 parts of quartz sand, 9 parts of waste glass, 21 parts of borax pentahydrate, 12 parts of soda ash, 11 parts of ammonium dihydrogen phosphate, 7.5 parts of calcium carbonate, 3 parts of potassium carbonate, 1.1 parts of zinc oxide, 2 parts of aluminum oxide powder, Put 2.3 parts of barium and 0.06 parts of cerium oxide into the mixer for stirring, stop when the uniformity is greater than 95%, add a small amount of water as needed, and the water content is 3-4% of the batch. Put the uniformly mixed raw materials into the furnace to melt, and the temperature of the furnace is controlled at about 1530°C, so that the material is melted into a liquid without bubbles and stones, and then cooled to 1300°C; when the raw material temperature is 1120°C, it is made by a centrifugal molding machine The dinner plate is heated and polished with fire after molding;

[0079] Put the polished molded product into the annealing furnace for annealing: the annealing furnace includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com