Low temperature gas carburizing method for realizing reinforcement and corrosion resistance of austenitic stainless steel

A technology of austenitic stainless steel and low-temperature gas, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., and can solve problems such as corrosion resistance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

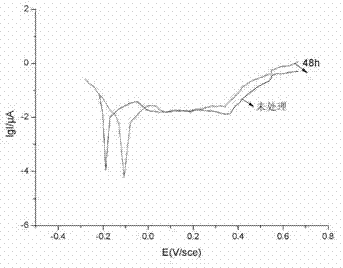

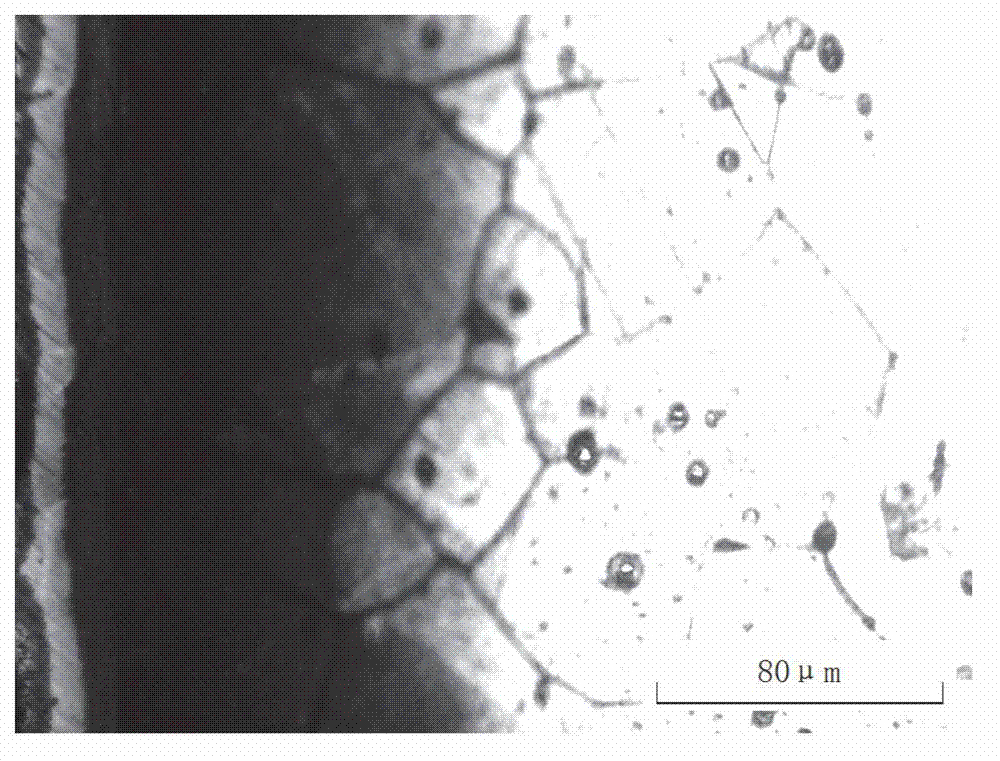

[0026] Embodiment 1: Implement low-temperature carburizing treatment to 304 austenitic stainless steel according to the treatment method of the present invention

[0027] First, degrease and dry the surface of 304 austenitic stainless steel parts with a mass of 20Kg, put them into the carburizing furnace, weigh 200g of polytetrafluoroethylene according to the specified proportion, put them into the bottom of the carburizing furnace, and cover the carburizing furnace tightly cover; then pass in protective nitrogen gas, turn on the electric heating until the temperature of the furnace rises to 550°C, keep it warm for 30 minutes, polytetrafluoroethylene decomposes at 535°C, and the decomposed products activate the passivation film on the surface of austenitic stainless steel; cool down To 470°C, evacuate the gas in the furnace, and pass 35%CO+10%H into the carburizing furnace 2 +55%N 2 Mix carburizing gas, keep warm for 48 hours, take out the test piece, and complete the low-tem...

Embodiment 2

[0028] Embodiment 2: Implement low-temperature carburizing treatment to 316 austenitic stainless steel according to the treatment method of the present invention

[0029] First, degrease and dry the surface of 316 austenitic stainless steel parts with a mass of 15Kg, put them into the carburizing furnace, weigh 102g of polytetrafluoroethylene according to the specified proportion, put them into the bottom of the carburizing furnace, and cover the carburizing furnace tightly cover; then pass in protective nitrogen gas, turn on the electric heating until the temperature of the furnace rises to 550°C, keep it warm for 30 minutes, polytetrafluoroethylene decomposes at 535°C, and the decomposed products activate the passivation film on the surface of austenitic stainless steel; cool down To 470°C, evacuate the gas in the furnace, and feed 38%CO+10%H into the carburizing furnace 2 +52%N 2 Mix carburizing gas, keep warm for 48 hours, take out the test piece, and complete the low-tempe...

Embodiment 3

[0030] Embodiment 3: Implement low-temperature carburizing treatment to 321 austenitic stainless steel according to the treatment method of the present invention

[0031] First, degrease and dry the surface of 321 austenitic stainless steel parts with a mass of 18Kg, put them into the carburizing furnace, weigh 90g of polytetrafluoroethylene according to the specified proportion, put them into the bottom of the carburizing furnace, and cover the carburizing furnace tightly Cover; then pass in protective nitrogen gas, turn on the electric heating until the temperature of the furnace rises to 550°C, keep warm for 30 minutes, polytetrafluoroethylene decomposes at 535°C, and the decomposed products activate the passive film on the surface of the austenitic stainless steel; cool down To 470°C, evacuate the gas in the furnace, and feed 25%CO+10%H into the carburizing furnace 2 +65%N 2 Mix carburizing gas, keep warm for 48 hours, take out the sample, and complete the low-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com