Tunneling field effect transistor

A tunneling field effect, transistor technology, applied in the direction of transistors, semiconductor devices, electrical components, etc., can solve the problems of small sub-threshold slope, small on-state current, etc., achieve low sub-threshold slope, low off-state current, improve open The effect of state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

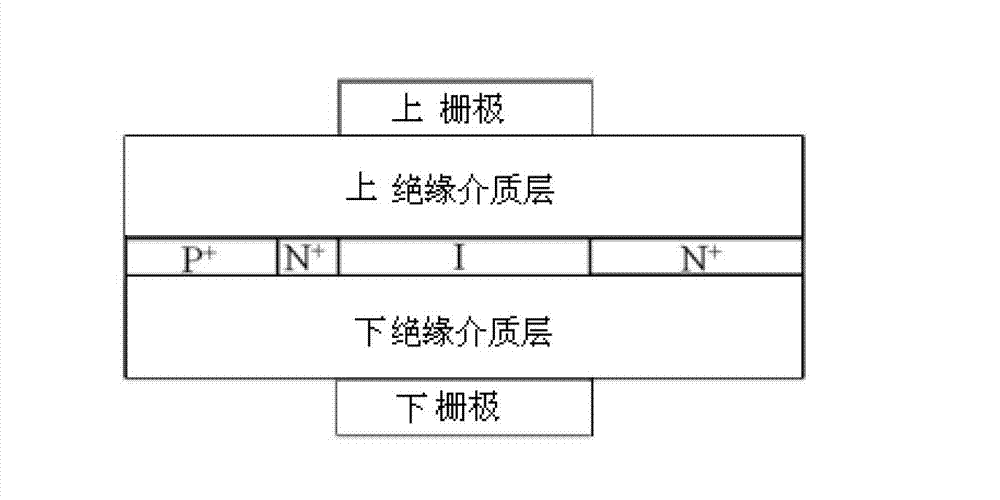

[0036] Such as figure 1 As shown, this embodiment provides a tunneling field effect transistor, including a source region, a channel region and a drain region, the source region and the drain region are respectively formed on both sides of the channel region, and the source region and the drain region The contact region of the channel region is made of extrinsic material, and the channel region is made of intrinsic material, and the doping type is different from that of the source region.

[0037] In this embodiment, the source region adopts P-type doping, the contact region between the source region and the channel region adopts N-type doping, the drain region adopts N-type doping, and the channel region adopts two-dimensional materials, such as graphene, Molybdenum disulfide (MoS2), silicene (Silicene), germanene (Germanene), boron nitride (BN), etc., preferably graphene.

[0038] In this embodiment, the tunneling field effect transistor further includes an upper insulating...

Embodiment 2

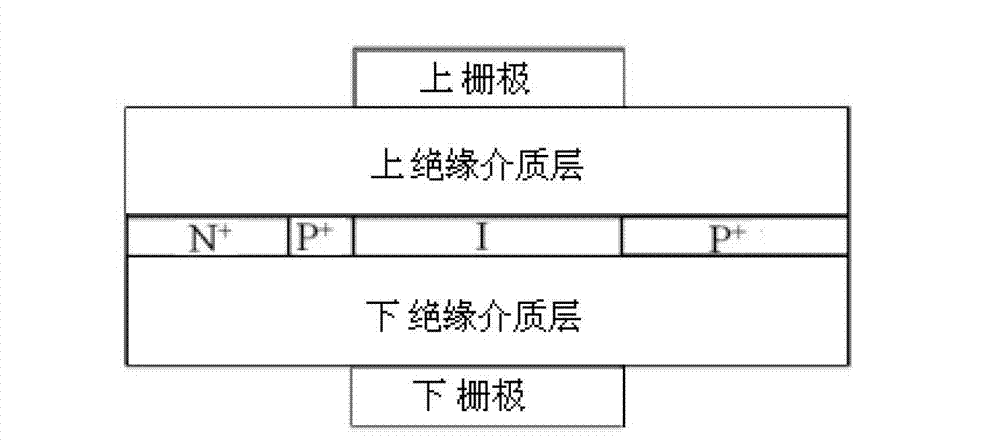

[0043] The structure of this embodiment is as figure 2 As shown, the difference between this embodiment and the first embodiment lies in that the doping method is different, so that it uses different carriers for transport. Specifically, in this embodiment, the source region is doped with N type, so The contact area between the source region and the channel region adopts P-type doping, and the drain region adopts P-type doping.

[0044] It can be seen that, compared with the structure of the N-I-P junction used in the traditional tunneling field effect transistor, in this embodiment, the part of the source close to the channel is doped with electrons, that is, P-type doping, and finally an N-P-I-P junction is formed, thereby forming NPIP type tunneling field effect transistor.

Embodiment 3

[0046] The structure of this embodiment is as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the two-layer structure composed of the lower gate and the lower insulating dielectric layer in the first embodiment is replaced by a substrate.

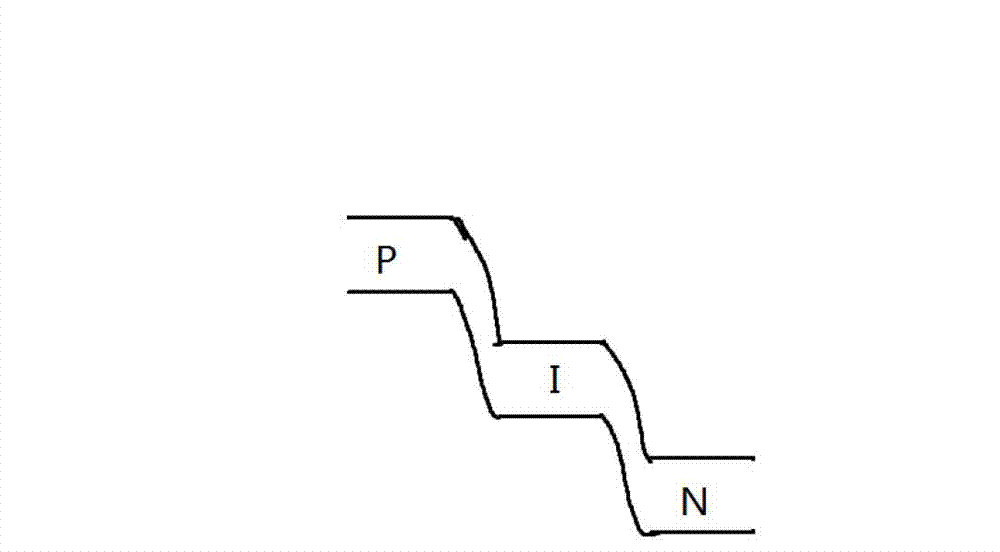

[0047] It can be seen from the above examples that since the doping at the contact between the source region and the channel region can form a structure similar to a PN junction in this part, the energy in the doped (for example N-type) region will move to the low energy direction , and then the conduction band bottom of the doped (for example N-type) region will be lower than the conduction band bottom of the channel. Figure 3a and Figure 3b shown), therefore, the present invention makes the device have a narrower tunneling layer thickness from the source end to the channel when the device is in the on state, thereby improving on-state current. Since the method does not change the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com