Water cooling die casting process of polygonal steel ingots, and water cooling die casting device

A water-cooled die-casting and polygonal technology, applied in ingot workshops, casting workshops, casting equipment, etc., can solve the problems of high labor intensity, short life of steel ingot molds, complicated cleaning, etc., and achieve high automation, low mold consumption, and transmission smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

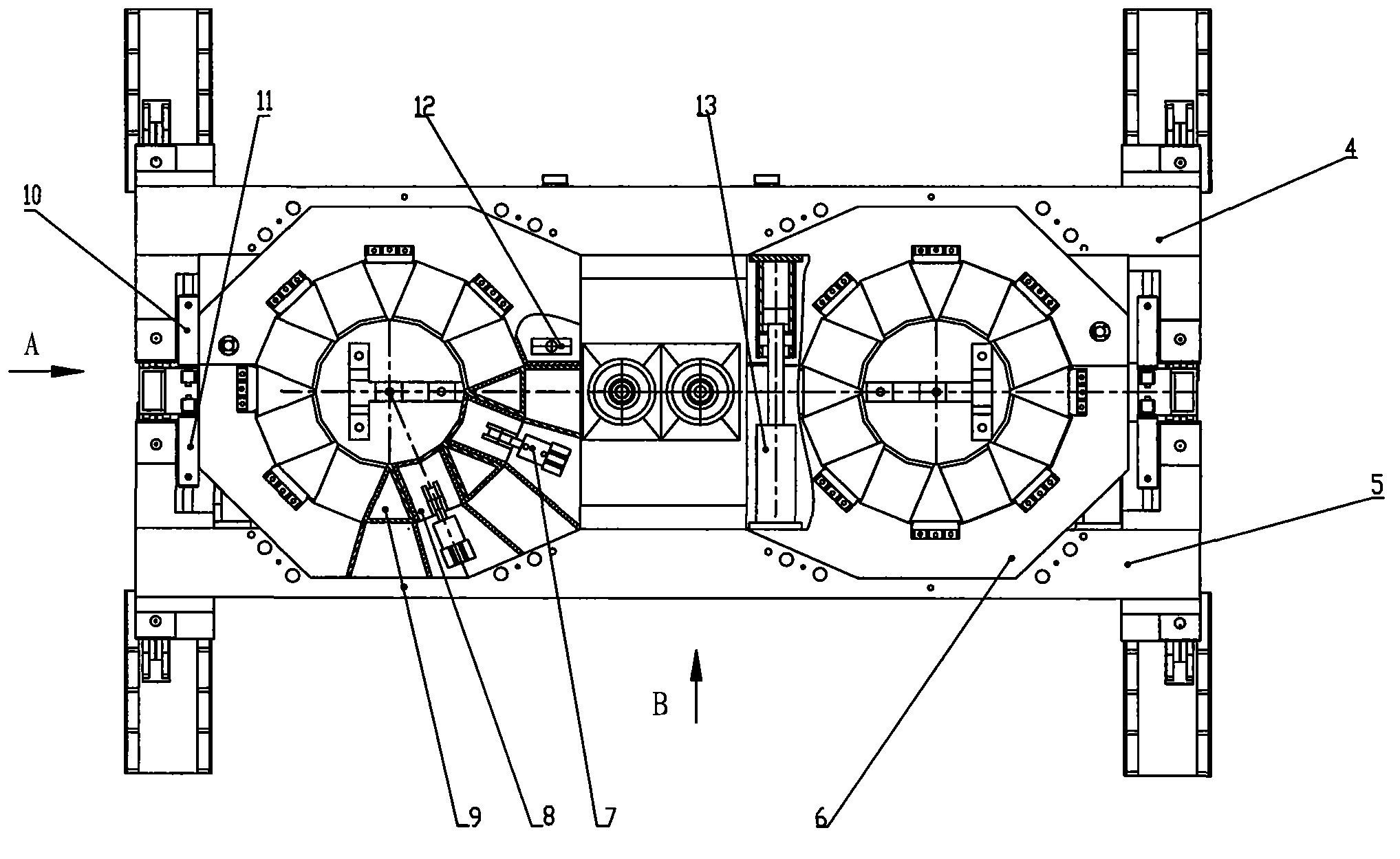

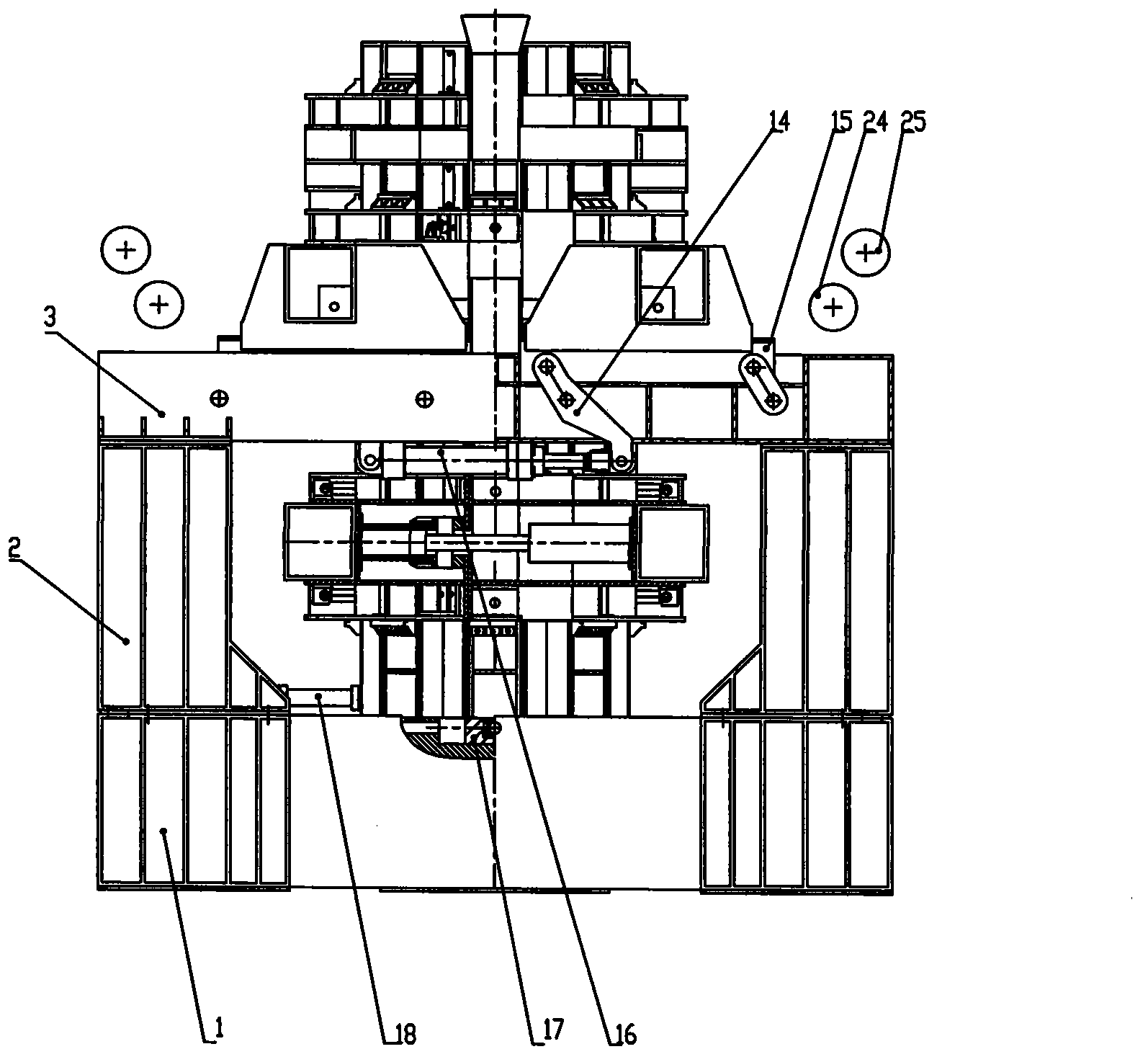

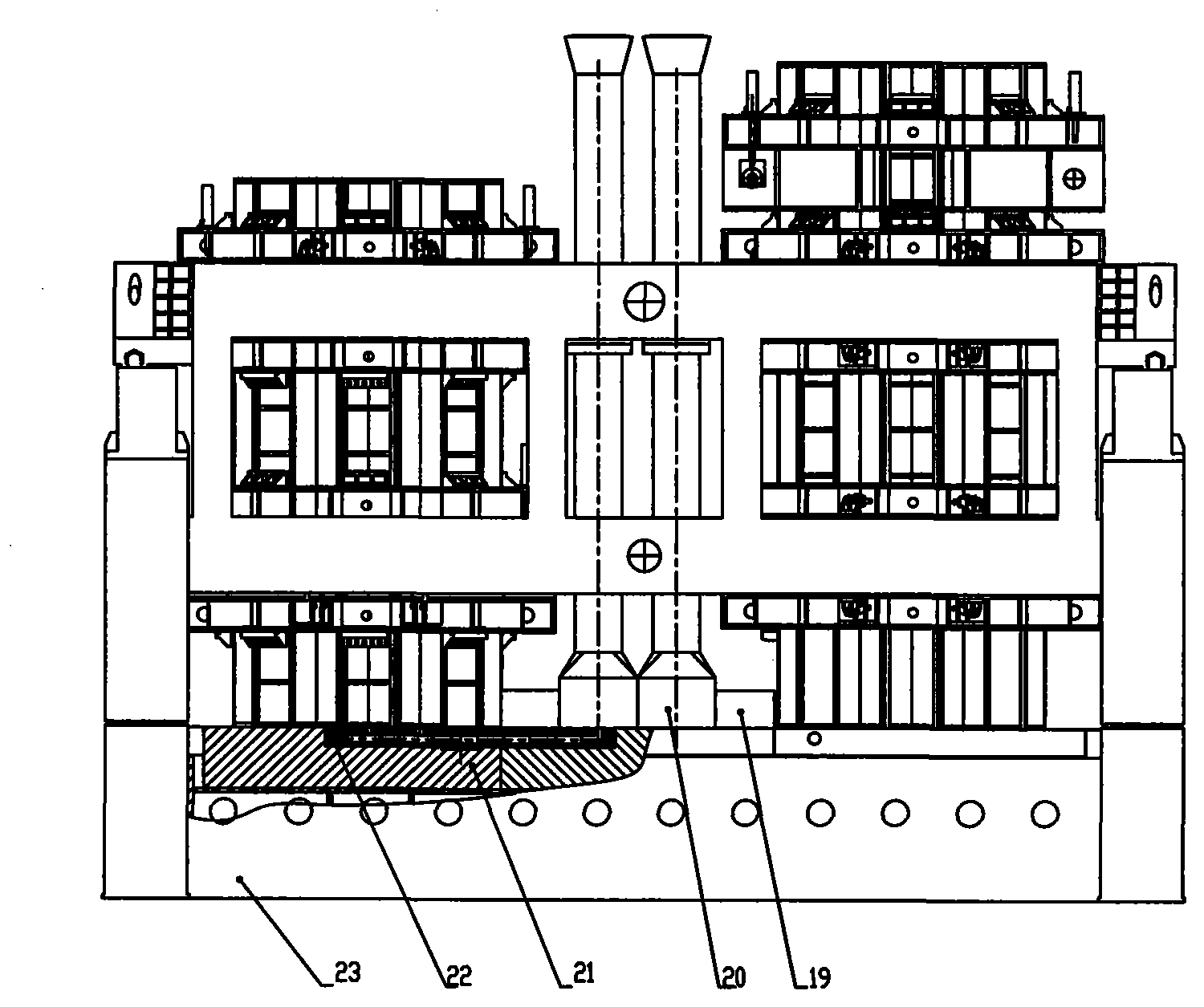

[0023] The invention mainly includes a main engine part, a hydraulic drive system, a cooling water circulation system, a molten steel pouring system, a power supply and an electro-hydraulic control system, a hydraulic combination hoist, an operating platform and a protective device. The host part includes a frame 1, a main body 4, an auxiliary body 5, a mold base 6, a chassis 21 and a bracket 23 thereof; The body opening and closing cylinder 11 and the connecting rod mechanism are movably connected with the frame; the body is provided with modules for casting polygonal (n sides) steel ingots, and each module consists of n / 2 main molds 8 and n / 2 corner molds 9 form an n-sided cavity; the upper end of the module is provided with a riser device, the lower end is seated on the pouring chassis 21, and the pouring chassis 21 is mounted on the bracket 23; the bracket 23 is rigidly connected with the frame 1 as a whole. The molten steel pouring system includes an intermediate injectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumcircle diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com