Polylactic acid block polymer and preparation method thereof

A technology of block copolymer and polylactic acid, which is applied in the field of polylactic acid block copolymer and its preparation, can solve the problems of wide molecular weight distribution of polymers and limited application scope, and achieves narrow molecular weight distribution, clear structure and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

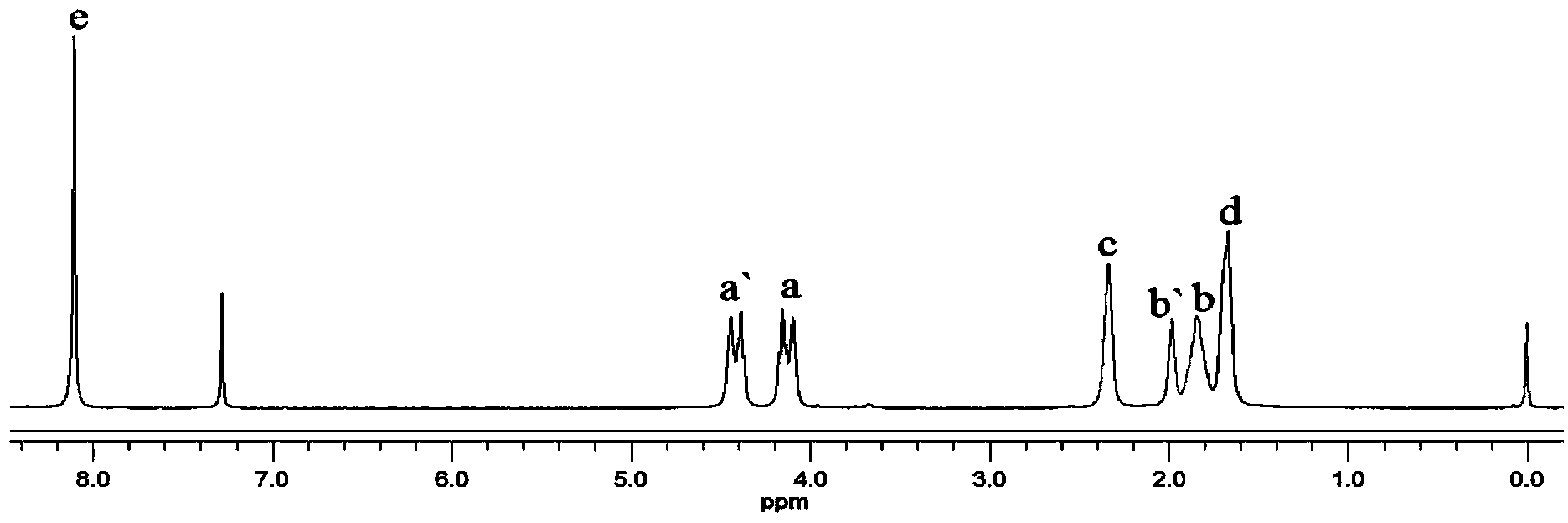

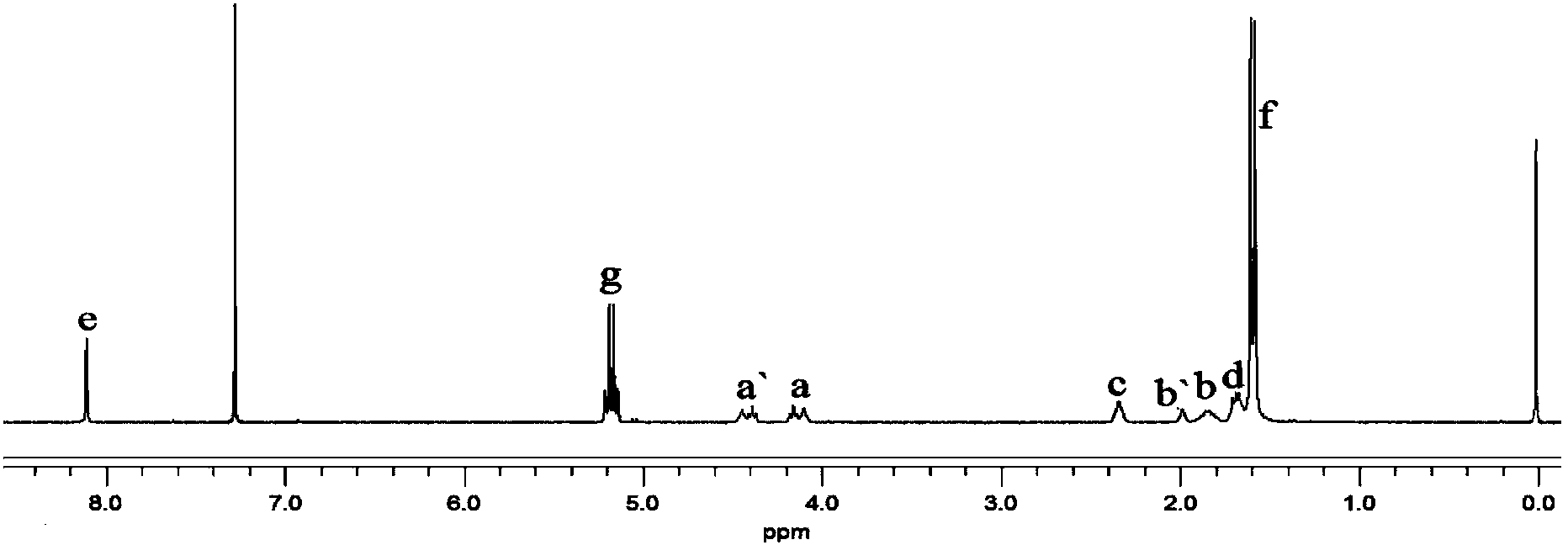

[0033] The present invention also provides a preparation method of polylactic acid block copolymer, comprising the following steps: mixing poly(adipic acid-terephthalic acid) butanediol copolyester, lactide and the first catalyst, heating To the molten state, after the reaction, the polylactic acid block copolymer with the structure of formula (I) is obtained. The polylactic acid block copolymer with the structure of formula (I) is the same as described above, and will not be repeated here.

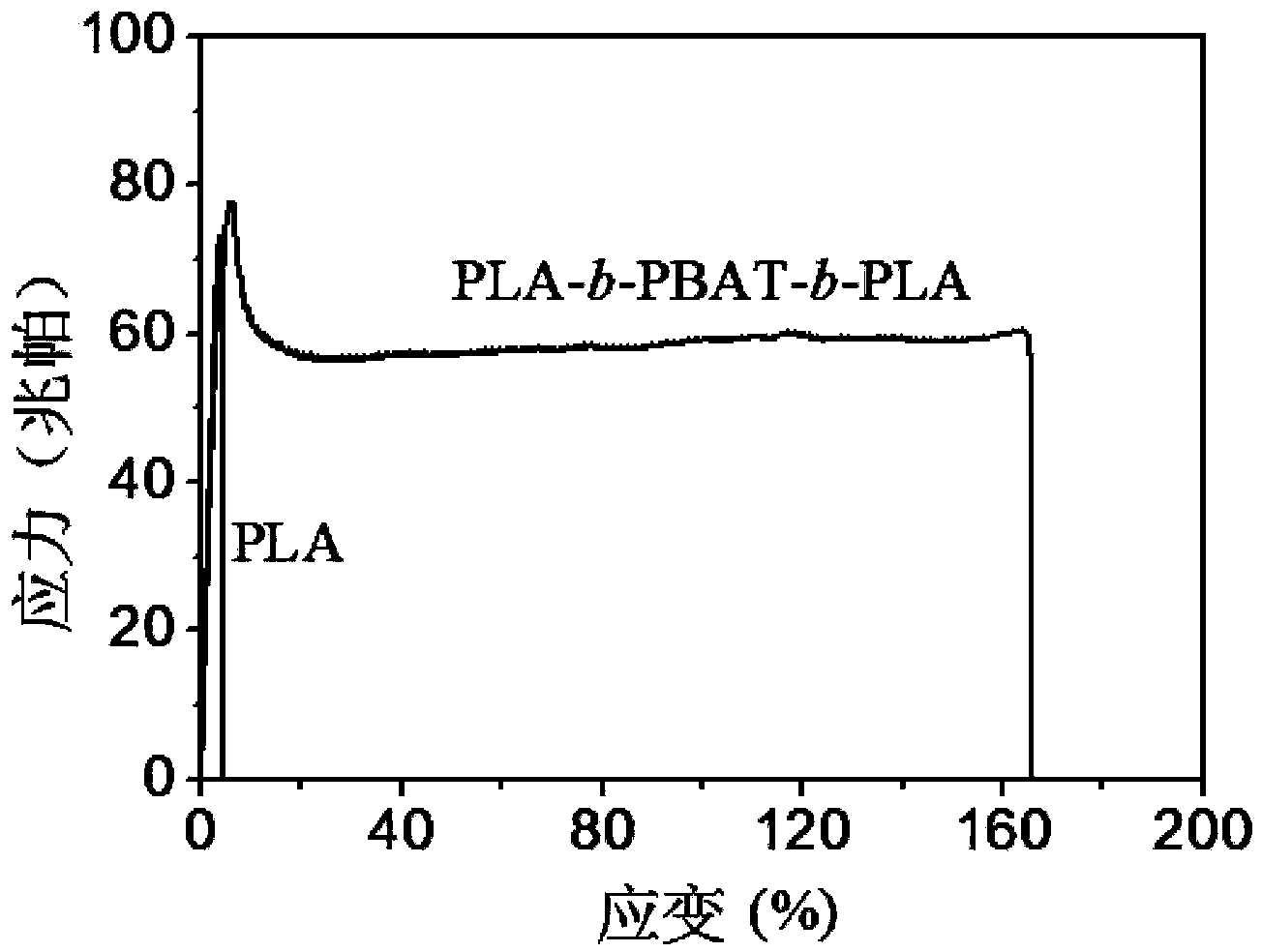

[0034] The mass ratio of lactide and poly(adipic acid-terephthalic acid) butanediol copolyester described in the present invention is (1:9)~(9:1), preferably (1:1)~ (6:1), more preferably (1.5:1)~(4:1), more preferably (1.5:1)~(3:1). Poly(adipic acid-terephthalic acid) butanediol copolyester has good flexibility, and the ring-opening polymerization of lactide to form a block copolymer can make up for the lack of flexibility and elasticity of polylactic acid.

[0035] The mass of the fir...

Embodiment 1

[0052] Under the condition of nitrogen protection, 83g of terephthalic acid, 73g of adipic acid, 90g of butanediol and 0.1g of tetrabutyl titanate were added to the reaction kettle with mechanical stirring, and the temperature was raised to 140°C under normal pressure. Carry out the esterification reaction, distill off the water until the theoretical water output is reached; then raise the temperature to 210°C, gradually reduce the pressure to a high vacuum state and the pressure is 100Pa, carry out the polycondensation reaction, set the stirring voltage to 120V, record the number of revolutions of the stirrer until the stirring The number of revolutions is no longer reduced to a fixed value, and the obtained; lower the temperature to 120°C, add 700g of dried lactide and 0.7g of stannous octoate, react for 12h, blow nitrogen to devolatilize, extrude and granulate, and obtain the formula (I) Structure of polylactic acid block copolymer, the relative number average molecular weig...

Embodiment 2

[0057] Under the condition of nitrogen protection, 83g of terephthalic acid, 73g of adipic acid, 90g of butanediol and 0.1g of tetrabutyl titanate were added to the reaction kettle with mechanical stirring, and the temperature was raised to 140°C under normal pressure. Carry out the esterification reaction, distill off the water until the theoretical water output is reached; then raise the temperature to 210°C, gradually reduce the pressure to a high vacuum state and the pressure is 100Pa, carry out the polycondensation reaction, set the stirring voltage to 120V, record the number of revolutions of the stirrer until the stirring The number of revolutions does not decrease any more and reaches a fixed value; lower the temperature to 120°C, add 460g of dried lactide and 0.46g of stannous octoate, react for 12 hours, pass nitrogen gas to devolatilize, extrude and granulate, and obtain the formula (I) The polylactic acid block copolymer has a relative number average molecular weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com