Preparation method for C.I. paratonere 49:1

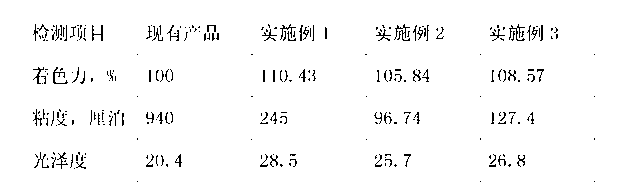

A technology of pigment red and pigment, which is applied in the field of preparation of C.I. Pigment Red 49:1, can solve the problems of low tinting power, poor gloss and high viscosity, and achieve high tinting power, gloss and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of diazo solution

[0023] Add 1000 liters of water to the diazo reactor, add 78.73 kg of 30% sodium hydroxide solution, add 128.38 kg of 100% 2-naphthylamine-1-sulfonic acid, add 100% 2-naphthylamine-1,5- Add 0.294 kg of disulfonic acid, add 5 kg of fatty alcohol polyoxyethylene (15) ether, stir to dissolve, the pH value of the mixed solution is 9, then add ice to cool to 0°C, add 165.41 kg of 30% hydrochloric acid dropwise, and then Add 133.28 kg of 30% sodium nitrite solution dropwise within 10 minutes, and continue to stir for 60 minutes until it is slightly blue when tested with starch-potassium iodide test paper, the temperature is 0-10°C, and the volume is adjusted to 3000 liters to obtain diazonium solution .

[0024] Wherein the molar ratio of sodium hydroxide to 2-naphthylamine-1-sulfonic acid is 1.026:1; the molar ratio of 2-naphthylamine-1,5-disulfonic acid to 2-naphthylamine-1-sulfonic acid is 0.00174:1; The molar ratio of hydrochloric aci...

Embodiment 2

[0037] (1) Preparation of diazo solution

[0038] Add 1000 liters of water to the diazo reactor, add 78.73 kg of 30% sodium hydroxide solution, add 128.38 kg of 100% 2-naphthylamine-1-sulfonic acid, add 100% 2-naphthylamine-1,5- Add 0.294 kg of disulfonic acid, add 10 kg of aliphatic amine polyoxyethylene (15) ether, stir to dissolve, the pH value of the mixed solution is 9, then add ice to cool to 0°C, add 165.41 kg of 30% hydrochloric acid dropwise, and then Add 133.28 kg of 30% sodium nitrite solution dropwise within 10 minutes, and continue to stir for 60 minutes until it is slightly blue when tested with starch-potassium iodide test paper, the temperature is 0-10°C, and the volume is adjusted to 3000 liters to obtain diazonium solution .

[0039] Wherein the molar ratio of sodium hydroxide to 2-naphthylamine-1-sulfonic acid is 1.026:1; the molar ratio of 2-naphthylamine-1,5-disulfonic acid to 2-naphthylamine-1-sulfonic acid is 0.00174:1; The molar ratio of hydrochloric ...

Embodiment 3

[0053] (1) Preparation of diazo solution

[0054] Add 1000 liters of water to the diazo reactor, add 78.73 kg of 30% sodium hydroxide solution, add 128.38 kg of 100% 2-naphthylamine-1-sulfonic acid, add 100% 2-naphthylamine-1,5- Add 0.294 kg of disulfonic acid, add 15 kg of fatty acid polyoxyethylene (9) ether, stir and dissolve, the pH value of the mixed solution is 9, then add ice to cool to 0°C, add 165.41 kg of 30% hydrochloric acid dropwise, and then Add 133.28 kg of 30% sodium nitrite solution dropwise within 1 minute, and continue to stir for 60 minutes until it is slightly blue when tested with starch-potassium iodide test paper, the temperature is 0-10°C, and the volume is adjusted to 3000 liters to obtain a diazonium solution.

[0055] Wherein the molar ratio of sodium hydroxide to 2-naphthylamine-1-sulfonic acid is 1.026:1; the molar ratio of 2-naphthylamine-1,5-disulfonic acid to 2-naphthylamine-1-sulfonic acid is 0.00174:1; The molar ratio of hydrochloric acid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com