Fluoropolymer coating solution and weather-resistant coating obtained therefrom

A technology of fluoropolymer and coating liquid, which is applied in the direction of coating, etc., can solve the problems of restricting the performance of fluoromaterials, the weather resistance of adhesives, the equivalent of fluoromaterials in chemical corrosion resistance, and the failure of the excellent characteristics of fluoromaterials to be realized as expected. , to achieve the effect of environmental protection, good chemical resistance and bright appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

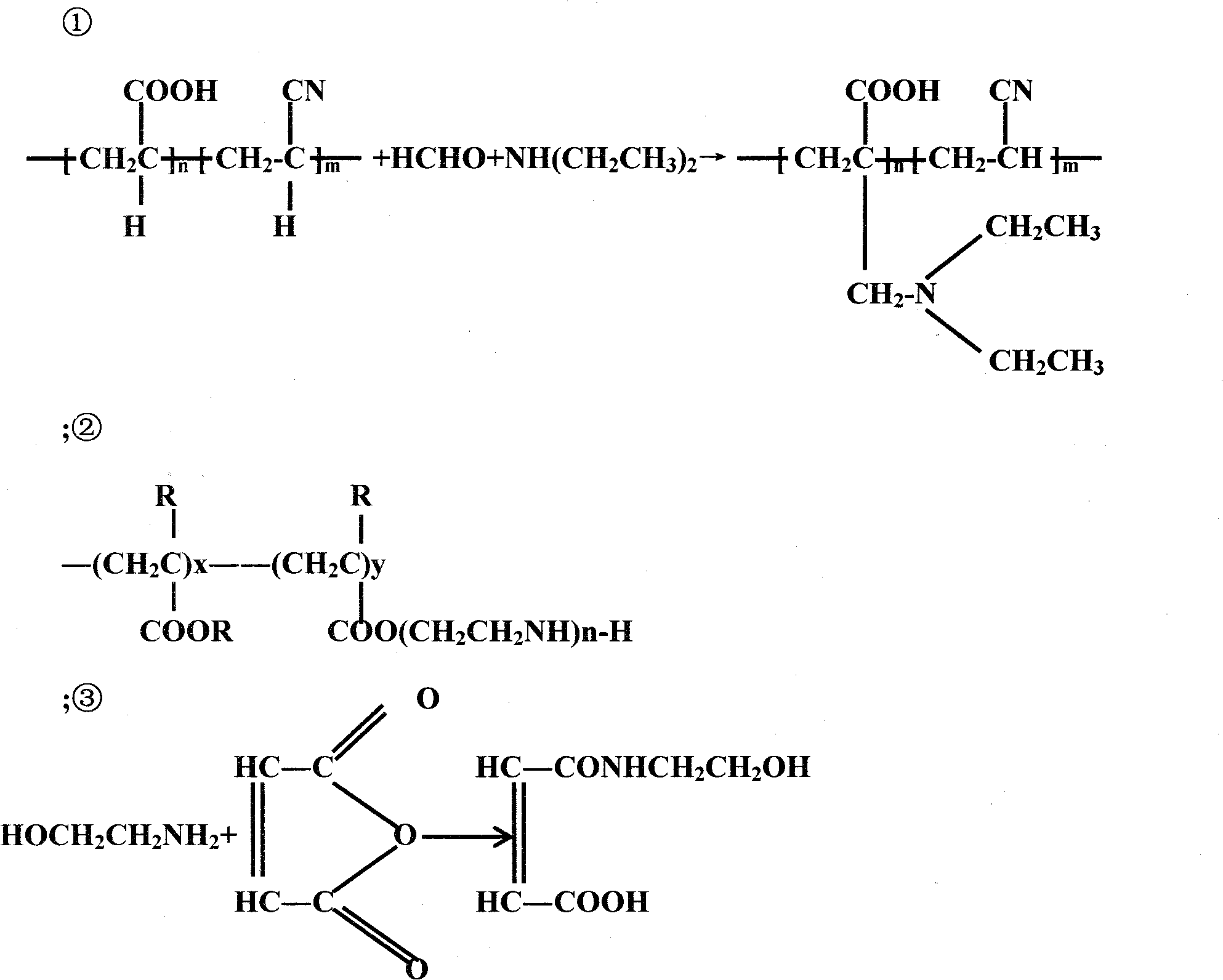

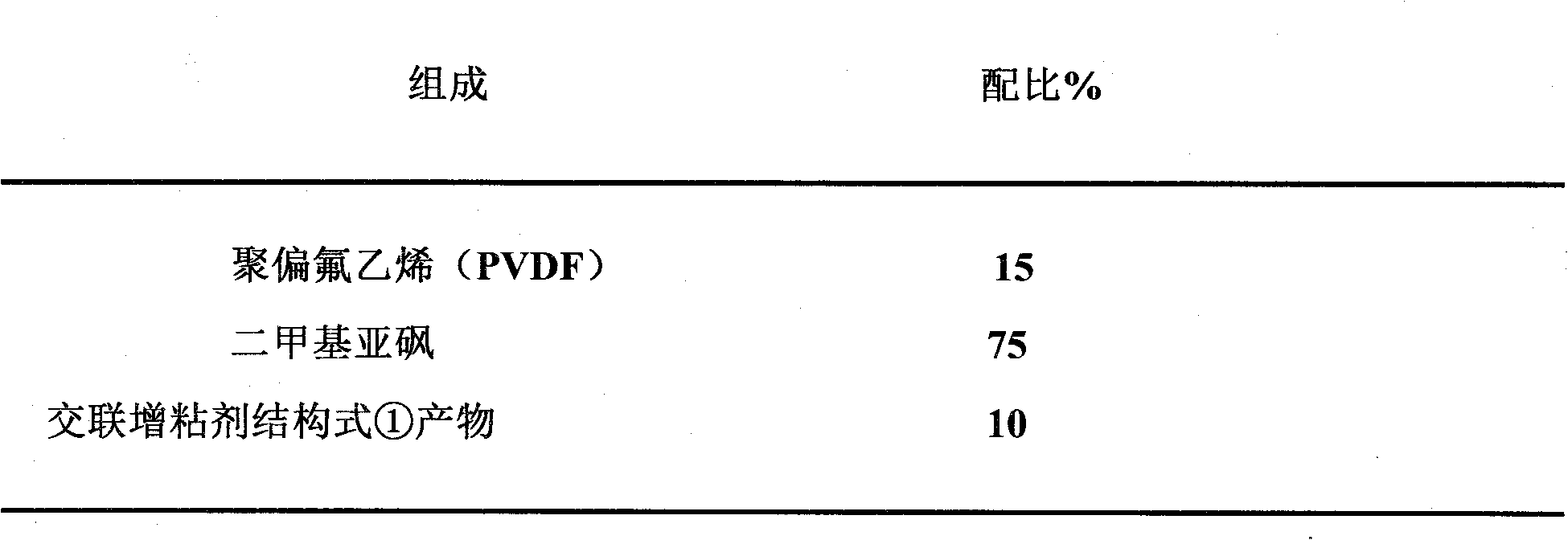

[0028] According to the following ratio, add polyvinylidene fluoride (PVDF) and dimethyl sulfoxide into a heatable container, and heat to 50°C-60°C under stirring to dissolve completely. After the temperature reaches 50°C-20°C, add the product of the crosslinking tackifier structural formula ①, stir and mix thoroughly to obtain the coating liquid (1). The coating solution does not produce gel phenomenon when stored at 10°C-40°C for 180 days, and has good storage stability.

[0029]

[0030] The coating solution (1) was sprayed on the aluminum plate, cured at room temperature for 30 minutes, and the coating thickness was 10 μm. The coating was divided into 1 cm squares with a knife, and the adhesive tape could not be peeled off.

Embodiment 2

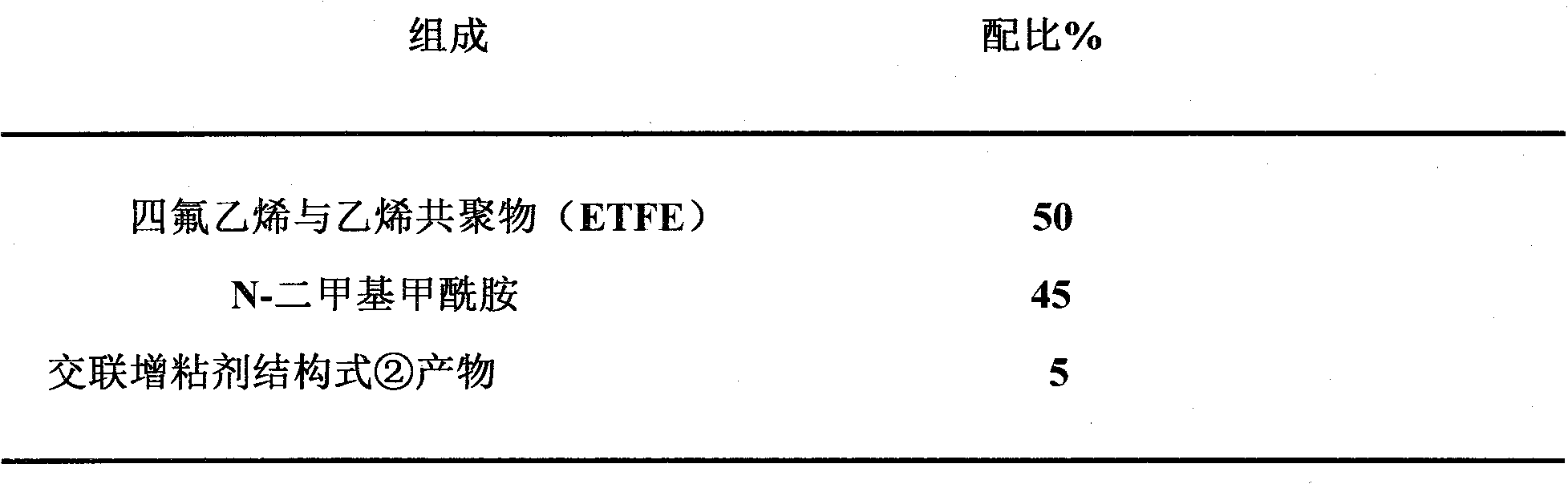

[0032]According to the following ratio, add tetrafluoroethylene and ethylene copolymer (ETFE) and N-dimethylformamide into a heatable container, and heat to 50°C-60°C under stirring to dissolve completely. After the temperature reaches 50°C-20°C, add the product of the crosslinking tackifier structural formula ②, stir and mix thoroughly to obtain the coating liquid (2). The coating solution does not produce gel phenomenon when stored at 10°C-40°C for 180 days, and has good storage stability.

[0033]

[0034] The coating solution (2) was coated onto a polyester (PET) substrate by a printing machine at a line speed of 100 m / min and a coating thickness of 20 μm. After the machine was off the machine, it could not be peeled off with an adhesive tape.

Embodiment 3

[0036] According to the following ratio, polyvinylidene fluoride (PVDF) and N-methylpyrrolidone, ethyl acetate, (mixing weight ratio 1: 1); titanium dioxide, antioxidant is added in a heatable container, and in Heat to 70°C-80°C while stirring, and dissolve completely. After the temperature reaches 30°C-20°C, add the product of the crosslinking tackifier structural formula ③, stir and mix thoroughly to obtain the coating liquid (3). The coating solution does not produce gel phenomenon when stored at 10°C-40°C for 180 days, and has good storage stability.

[0037]

[0038] The coating liquid (3) was coated on the steel plate by roller coating method, cured at room temperature for 30 minutes, and the coating thickness was 35 μm. The coating was divided into 1 cm squares with a knife, and the adhesive tape could not be peeled off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com