Preparation method of phosphotungstic acid/polyvinyl alcohol composite proton exchange membrane

A proton exchange membrane, polyvinyl alcohol technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high methanol permeability, uneven distribution of nano-scale phosphotungstic acid particles, etc. Simple process, good alcohol resistance and excellent proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

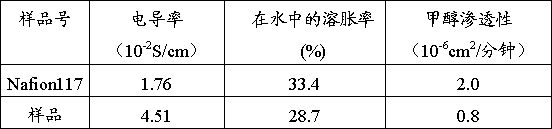

[0031] Dissolve 14 grams of polyvinyl alcohol in 180 milliliters of water to form solution A. Heat solution A to 95°C and stir for 2 hours to obtain solution B. When the temperature drops to 70°C, add 3.89g concentrated phosphoric acid and 4.44g tungstic acid to solution B Sodium and 0.44g oxalic acid were stirred at a temperature of 85°C for 2 hours and then cooled to room temperature to form a uniform solution C; the solution C was poured on a polytetrafluoroethylene plate and dried to form a film, and the film thickness was controlled at 0.12 mm. Phosphotungstic acid-polyvinyl alcohol composite proton exchange membrane was obtained after vacuum drying at 90°C for 7 hours.

[0032] Soak the membrane in deionized water for 12 hours before use. The conductivity was measured by the two-electrode AC impedance method, and the swelling degree ( SD ) to characterize the swelling behavior of the membrane, first cut the dry membrane into a rectangular membrane with a size of a...

Embodiment 2

[0036] Dissolve 7 grams of polyvinyl alcohol in 130 milliliters of water to form solution A. Heat solution A to 85°C and stir for 1.5 hours to obtain solution B. When the temperature drops to 65°C, add 1.13g concentrated phosphoric acid and 1.46g tungstic acid to solution B Sodium and 0.29g oxalic acid were stirred at a temperature of 80°C for 2 hours and then cooled to room temperature to form a uniform solution C; the solution C was poured on a polytetrafluoroethylene plate and dried to form a film, the film thickness was controlled at 0.1 mm, Phosphotungstic acid-polyvinyl alcohol composite proton exchange membrane was obtained after vacuum drying at 80°C for 6 hours.

Embodiment 3

[0038] Dissolve 10g of polyvinyl alcohol in 170ml of water to form solution A, heat solution A to 90°C, stir for 2 hours to obtain solution B, lower the temperature to 60°C, add 1.67g of concentrated phosphoric acid and 2.43g of tungstic acid to solution B Sodium and 0.43g oxalic acid were stirred at a temperature of 90°C for 2 hours and then cooled to room temperature to form a uniform solution C; the solution C was poured on a polytetrafluoroethylene plate and dried to form a film, the film thickness was controlled at 0.15 mm, Phosphotungstic acid-polyvinyl alcohol composite proton exchange membrane was obtained after vacuum drying at 85°C for 7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com