Water-retaining organic fertilizer and preparation method thereof

An organic fertilizer and water-retaining technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve the problems of crop yield reduction, nutrient loss, and non-availability, so as to reduce leakage and loss, improve soil structure, The effect of high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

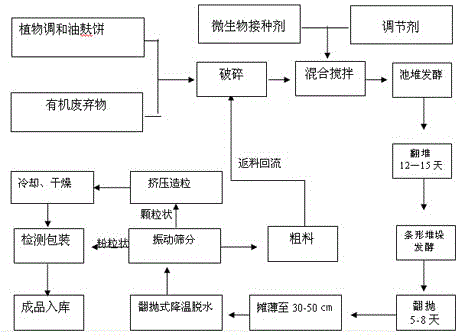

[0056] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0057] (1) Select 4300kg of plant blended oil bran cake and 5400kg of mushroom slag, classify and crush the above materials, then add 250kg of monosodium glutamate waste liquid and 50kg of organic waste fermentation koji, mix and stir the above materials to obtain fermentation raw materials, The moisture content of the fermentation raw material is 45%, the C / N is 29:1, the organic matter content is 55%, and the pH value is 6.5;

[0058] (2) Transfer the above-mentioned fermentation raw materials to the fermentation tank for composting and fermentation. The temperature rises to 55-60°C for the first turn over, and then when the temperature rises to 65°C, turn the pile once every one to two days; after 12-15 days of fermentation, the materials Transfer to the greenhouse and ferment in strip-shaped stacks on the ground. The strip-shaped stacks are 1m high, 2m wide, a...

Embodiment 2

[0060] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0061] (1) Select 9800kg of plant blended oil bran cake and 9000kg of chicken manure, classify and crush the above materials, then add 1060kg of monosodium glutamate waste liquid and 140kg of organic waste fermentation koji, mix and stir the above materials to obtain fermentation raw materials, The moisture content of the fermentation raw material is 48%, the C / N is 26:1, the organic matter content is 52%, and the pH value is 7;

[0062] (2) Transport the above-mentioned fermentation raw materials to the fermentation tank for composting and fermentation, turn the compost for the first time when the temperature rises to 55-60°C, and then turn the compost once every one to two days when the temperature rises to 68°C; ferment the material after 12-15 days Transfer to the greenhouse and ferment in strip-shaped stacks on the ground. The strip-shaped stacks are 1m high,...

Embodiment 3

[0064] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0065] (1) Select 9000kg of plant blended oil bran cake, 4570kg of mushroom dregs, and 5630kg of chicken manure, classify and crush the above materials, then add 600kg of monosodium glutamate waste liquid and 200kg of organic waste fermentation koji, and mix and stir the above materials , to obtain the fermentation raw material, the moisture content of the fermentation raw material is 43%, the C / N is 31: 1, the organic matter content is 56%, and the pH value is 8;

[0066] (2) Transport the above-mentioned fermentation raw materials to the fermentation tank for composting and fermentation, turn the compost for the first time when the temperature rises to 55-60°C, and then turn the compost once every one to two days when the temperature rises to 70°C; ferment the material after 12-15 days Transfer to the greenhouse and ferment in strip-shaped piles on the ground. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com