Plastic composition, plastic and preparation method of the plastic

A technology of plastic composition and polymer, applied in the field of plastic composition, can solve the problems of poor mechanical properties, no fragrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

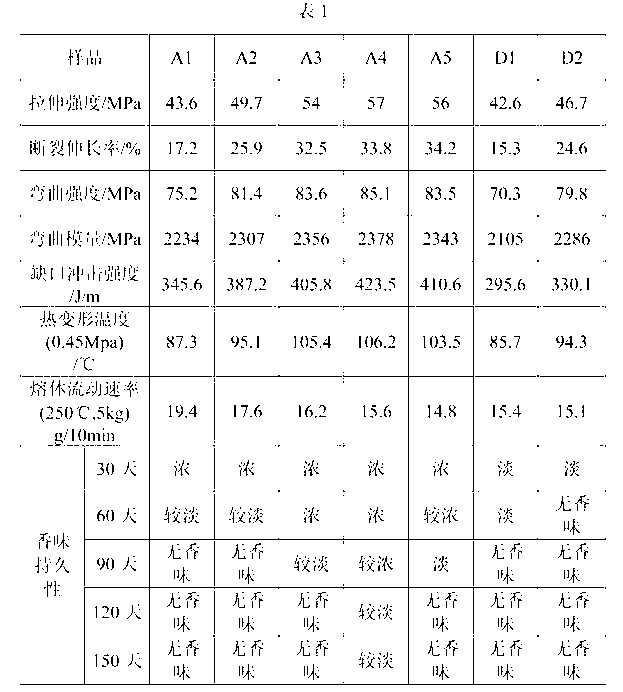

Examples

preparation example Construction

[0032] During the preparation process of the above-mentioned plastics, the presence of moisture will have a great influence on the properties of the prepared plastics. Therefore, preferably, when preparing the above-mentioned plastic, firstly, each component in the plastic composition is dried at 0.04-0.08 MPa, 30-120° C. for 4-8 hours to remove moisture in the plastic composition. The plastic composition is then melt-extruded in an extruder. The method of said melt extrusion is well known to those skilled in the art, for example, it can be 180-250r / min when the aspect ratio is 20-40, the screw speed is 180-250r / min, and the temperature of each section is respectively 140-160 ℃, 220-230℃, 230-240℃, 230-245℃, 230-245℃, 240-245℃, 240-245℃, 240-250℃, 240-250℃, 245-255℃, each section The melt extrusion is carried out under the condition that the vacuum degree is 0.02-0.06MPa.

[0033]In the above method, the degree of vacuum is the absolute pressure. The extrusion can be carrie...

Embodiment 1

[0037] This example is used to illustrate the plastic composition, plastic and its preparation method provided by the present invention.

[0038] 1. Raw material pretreatment

[0039] Polylactic acid (polylactic acid produced by Natureworks, USA, injection molding grade, viscosity-average molecular weight: 200,000, melting point: 165°C), polycarbonate, and mint flavor were dried at 0.08 MPa and 120°C for 4 hours.

[0040] Put ethylene-ethyl acrylate-glycidyl methacrylate (the content of glycidyl methacrylate is 5wt%) in a vacuum drying oven, and dry at 0.06MPa and 50°C for 4h.

[0041] 2. Raw material mixing and extrusion

[0042] Take 100 parts by weight of the above-mentioned treated polylactic acid (water content is 0.02wt%), 180 parts by weight of polycarbonate, 5 parts by weight of mint essence and 13 parts by weight of ethylene-ethyl acrylate-glycidyl methacrylate In the screw extruder, when the length-to-diameter ratio is 25, the screw speed is 180r / min, and the tempe...

Embodiment 2

[0046] This example is used to illustrate the plastic composition, plastic and its preparation method provided by the present invention.

[0047] 1. Raw material pretreatment

[0048] Polylactic acid (polylactic acid produced by Natureworks, USA, injection molding grade, viscosity-average molecular weight: 250,000, melting point: 170°C), polycarbonate, and lemon essence were dried at 0.08 MPa and 110°C for 4 hours.

[0049] Put ethylene-propyl acrylate-glycidyl methacrylate (the content of glycidyl methacrylate is 8wt%) in a vacuum drying oven, and dry at 0.06MPa and 50°C for 4h.

[0050] 2. Raw material mixing and extrusion

[0051] Take 100 parts by weight of the above-mentioned treated polylactic acid (water content is 0.02wt%), 200 parts by weight of polycarbonate, 6 parts by weight of lemon essence and 18 parts by weight of ethylene-propyl acrylate-glycidyl methacrylate, 1 weight part Part four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com