Special antiscaling agent for water heater

A descaling agent and water heater technology, which is applied in the field of chemical cleaning materials, can solve the problems of poor metal protection ability, etc., and achieve the effect of small metal corrosion, strong descaling ability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

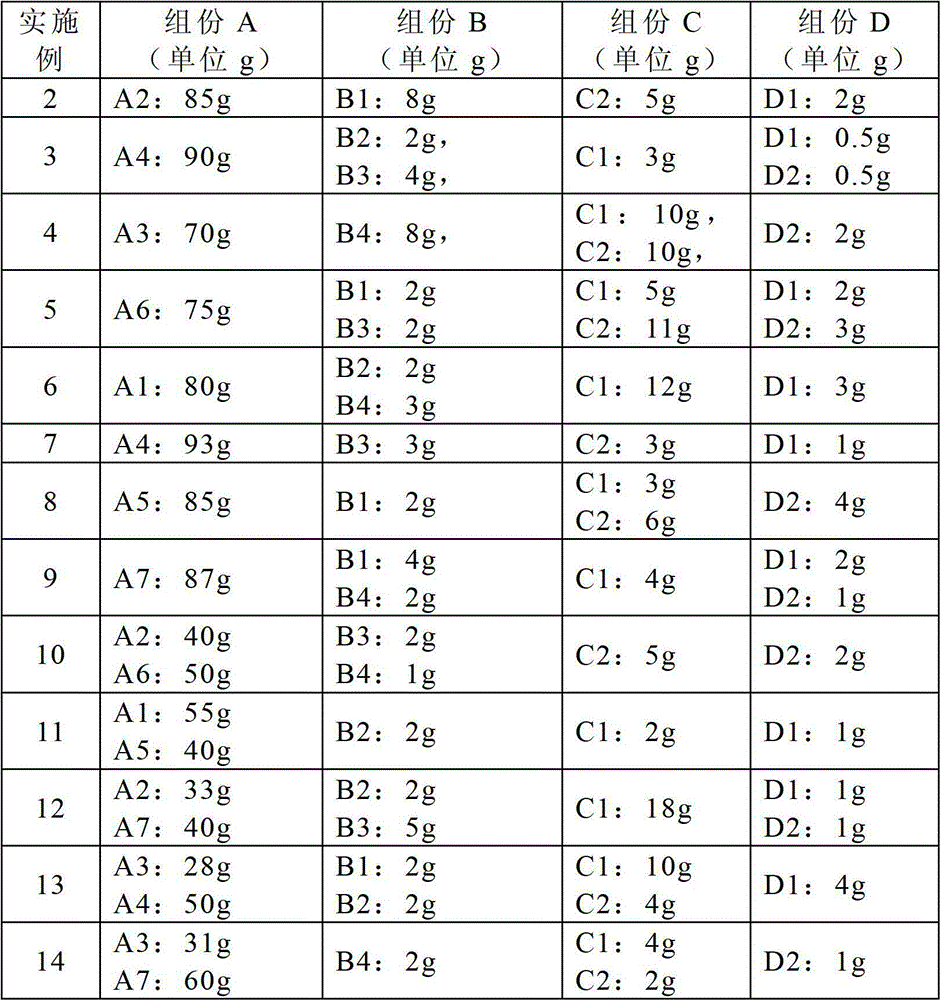

[0019] A special descaling agent for water heaters, which is made by mixing components A, B, C and D, wherein:

[0020] Component A is an acid descaling component, selected from one or two of citric acid, sulfamic acid, malic acid, tartaric acid, maleic acid, ethylenediaminetetraacetic acid, trichloroacetic acid, preferably sulfamic acid, Its weight percentage is 70%-95%, preferably 80%-90%, and the purity is 95-99.5%.

[0021] Component B is a binder, selected from one or both of polymer water-soluble rubber powder, sodium metasilicate, sodium carboxymethylcellulose, and cohesive polyvinyl alcohol, preferably sodium metasilicate, which The weight percentage is 2%-8%, preferably 4%-6%, and the purity is 90%-99%.

[0022] Component C is a metal ion chelating agent and a curing agent, selected from one or both of ethylenediaminetetraacetic acid disodium salt (i.e. EDTA disodium salt) and sodium pyrophosphate, preferably sodium pyrophosphate, and its weight percentage 2% to 20%...

Embodiment 1

[0026] Embodiment 1: a kind of descaling agent special for water heater, is made up of A, B, C, D four kinds of components, and wherein component A is citric acid 90g, and purity is 99.5%; Component B is sodium metasilicate 5g, The purity is 99%; component C is sodium pyrophosphate 4g, the purity is 99%; component D is sodium dodecylbenzenesulfonate 1g. The descaling agent with the above four components is made into a cylinder with a diameter of 12mm and a height of 60mm. The descaling agent was tested as follows:

[0027] (1) Descaling effect measurement:

[0028] Weigh 10g of the descaling agent solidified according to the above formula, put it into a beaker filled with 500ml of water, the cylinder disintegrates immediately, then weigh 6g of the scale scraped from the inner tank of the water heater, put it into the beaker, you can see A large number of bubbles came out and the reaction was violent. After at least 15 minutes, the scale was completely decomposed. It shows t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com