Method for preparing low-stress GaN film

A low-stress, thin-film technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of performance degradation of GaN-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

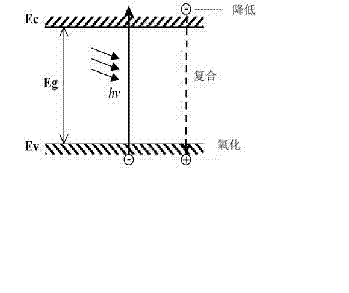

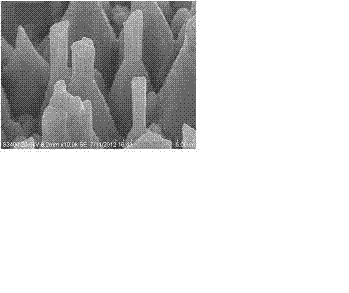

[0019] The method and process of the present invention include several parts: GaN nanostructure obtained by light-assisted electrodeless corrosion of GaN / sapphire composite substrate (referring to GaN grown on sapphire substrate); HVPE regrowth of low-stress GaN thin film.

[0020] Furthermore, the distribution and scale of the nanostructured GaN pillars can be controlled through the selection of etching time and solvent concentration (the more intense the corrosion and the longer the etching time, the thinner the size distribution and the smaller the size of the GaN pillars). In HVPE lateral epitaxy, self-separation between GaN film and sapphire can also be achieved, thereby obtaining a low-stress self-supporting GaN substrate material.

[0021] One of the technical implementations of the present invention is to prepare a low-stress GaN thin film, including the following steps:

[0022] 1. Cleaning and processing of GaN / sapphire composite substrate. The samples were ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com