Method for preparing polymeric benzophenone derivative photoinitiator

A technology of benzophenone and photoinitiator is applied in the field of preparation of polymerizable benzophenone derivative photoinitiator, which can solve the problems of easy volatility, small molecular weight, toxicity and the like, and achieves improved compatibility and reduced volatility. and migratory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

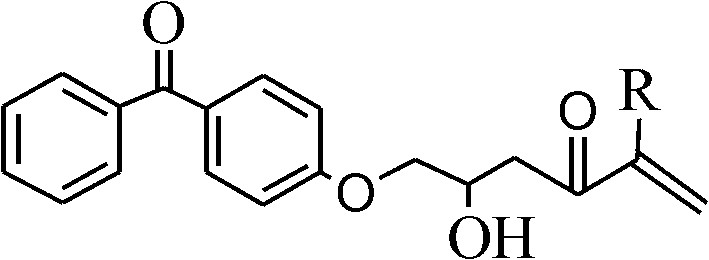

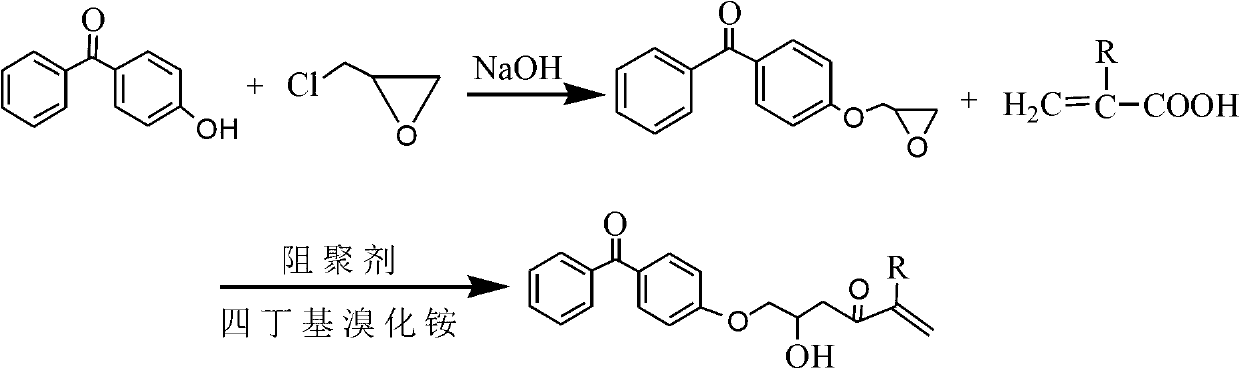

[0023] Dissolve 0.05g of p-hydroxyanisole and 0.05g of tetrabutylammonium bromide in 3.3g of acrylic acid, slowly add dropwise to 10.5g of 4-(2,3-epoxypropoxy)diphenyl In ketone (EBP), heat and stir, the temperature is controlled at 85°С, the dropwise addition is completed in 2 hours, the temperature rises to 100°С, the reaction is completed in 2 hours, cooled to room temperature, dissolved in dichloromethane, and mixed with 10mL 2% NaOH solution, deionized water were washed 2 times, anhydrous sodium sulfate dried overnight, filtered, rotary evaporation to remove dichloromethane, vacuum-dried to obtain a polymerizable benzophenone derivative photoinitiator 4—(acrylic acid-2- hydroxypropyl-3-oxy)benzophenone. The structure is shown in structural formula 1: 1 H NMR (250MHz) in CDCl 3 : δ2ppm (1H, OH), 3.95ppm (1H, CH), 3.09, 4.09ppm (4H, CH 2 ), 6.12-6.37ppm (3H, CH=CH 2 ), 6.87-7.70ppm (9H, benzene ring)

[0024]

Embodiment 2

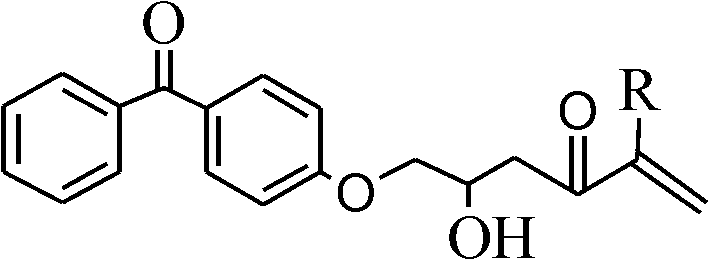

[0026] Dissolve 0.04g of p-hydroxyanisole and 0.05g of tetrabutylammonium bromide in 3.3g of methacrylic acid, slowly add dropwise to 10.5g of 4-(2,3-epoxypropoxy) In benzophenone (EBP), heat and stir, the temperature is controlled at 85 ° С, 2h dropwise is completed, the temperature rises to 100 ° С, 2h reaction is completed, cooled to room temperature, it is dissolved in dichloromethane, with 10mL2 % NaOH solution and deionized water were washed 2 times respectively, dried over night with anhydrous sodium sulfate, filtered, rotary evaporated to remove dichloromethane, and dried in vacuum to obtain a polymerizable benzophenone derivative photoinitiator 4—(methacrylic acid -2-hydroxypropyl-3-oxy)benzophenone. The structure is shown in structural formula 2: 1 H NMR (250MHz) in CDCl 3 : δ1.93ppm (3H, CH 3 ), 2ppm (1H, OH), 3.95ppm (1H, CH), 3.09, 4.09ppm (4H, CH 2 ), 5.90, 6.09ppm (2H, C=CH 2 ), 6.87-7.70ppm (9H, benzene ring)

[0027]

Embodiment 3

[0029] Dissolve 0.04g of p-hydroxyanisole and 0.06g of tetrabutylammonium bromide in 3.3g of hydroxyethyl acrylate, and slowly add it dropwise to 11.5g of 4-(2,3-epoxypropoxy ) in benzophenone (EBP), heated and stirred, the temperature was controlled at 90 ° С, the dropwise addition was completed in 2 hours, the temperature rose to 100 ° С, the reaction was completed in 2 hours, cooled to room temperature, dissolved in dichloromethane, and used 10mL of 2% NaOH solution and deionized water were washed twice respectively, dried overnight over anhydrous sodium sulfate, filtered, rotary evaporated to remove methylene chloride, and dried in vacuo to obtain a polymerizable benzophenone derivative photoinitiator 4—(propylene Acyloxy-4-hydroxy-3,5-dioxy)benzophenone. The structure is shown in structural formula 3: 1 H NMR (250MHz) in CDCl 3 : δ2ppm (1H, OH), 3.65, 4.26, 4.32ppm (6H, CH 2 ), 5.08ppm (1H, CH), 5.80, 6.05, 6.43ppm (3H, CH=CH 2 ), 6.87-7.70ppm (9H, benzene ring)

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com