Brake cylinder of wind power unit and manufacturing method thereof

A technology for wind power equipment and brakes, which is used in manufacturing tools, brake actuators, mechanical equipment, etc., can solve the problems of high internal stress, endanger safety, and high manufacturing costs, improve low-temperature impact resistance, save production costs, and reduce The effect of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

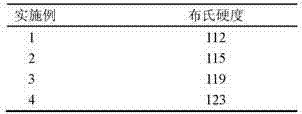

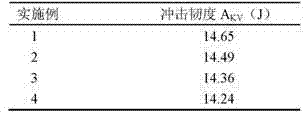

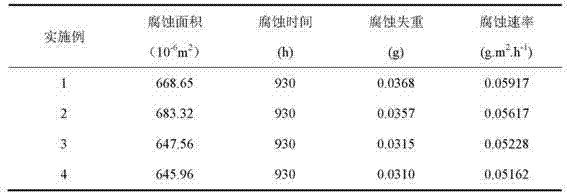

Embodiment 1

[0031]The chemical composition of the low-temperature high-toughness corrosion-resistant ductile iron material used in this example is: C 3.79%, Si 1.80%, Mn 0.19%, Ni 0.30%, P 0.025%, S 0.016%, Mg 0.038%, rare earth 0.028%, and The amount is Fe;

Embodiment 2

[0033] The chemical composition of the low-temperature high-toughness corrosion-resistant ductile iron material used in this example is: C 3.80%, Si 1.90%, Mn 0.20%, Ni 0.31%, P 0.022%, S 0.018%, Mg 0.036%, rare earth 0.029%, and The amount is Fe;

Embodiment 3

[0035] The chemical composition of the low-temperature high-toughness corrosion-resistant ductile iron material used in this example is: C 3.82%, Si 1.95%, Mn 0.20%, Ni 0.28%, P 0.023%, S 0.016%, Mg 0.039%, rare earth 0.028%, and The amount is Fe;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com