Direct-current support capacitor capable of effectively absorbing high-frequency harmonic waves

A high-frequency harmonic and DC support technology, applied in the field of capacitors, can solve the problems of uneven heating of capacitors, reduced capacitor life, easy to exceed the core, etc., to achieve uniform current distribution, reduced heat generation, and good product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

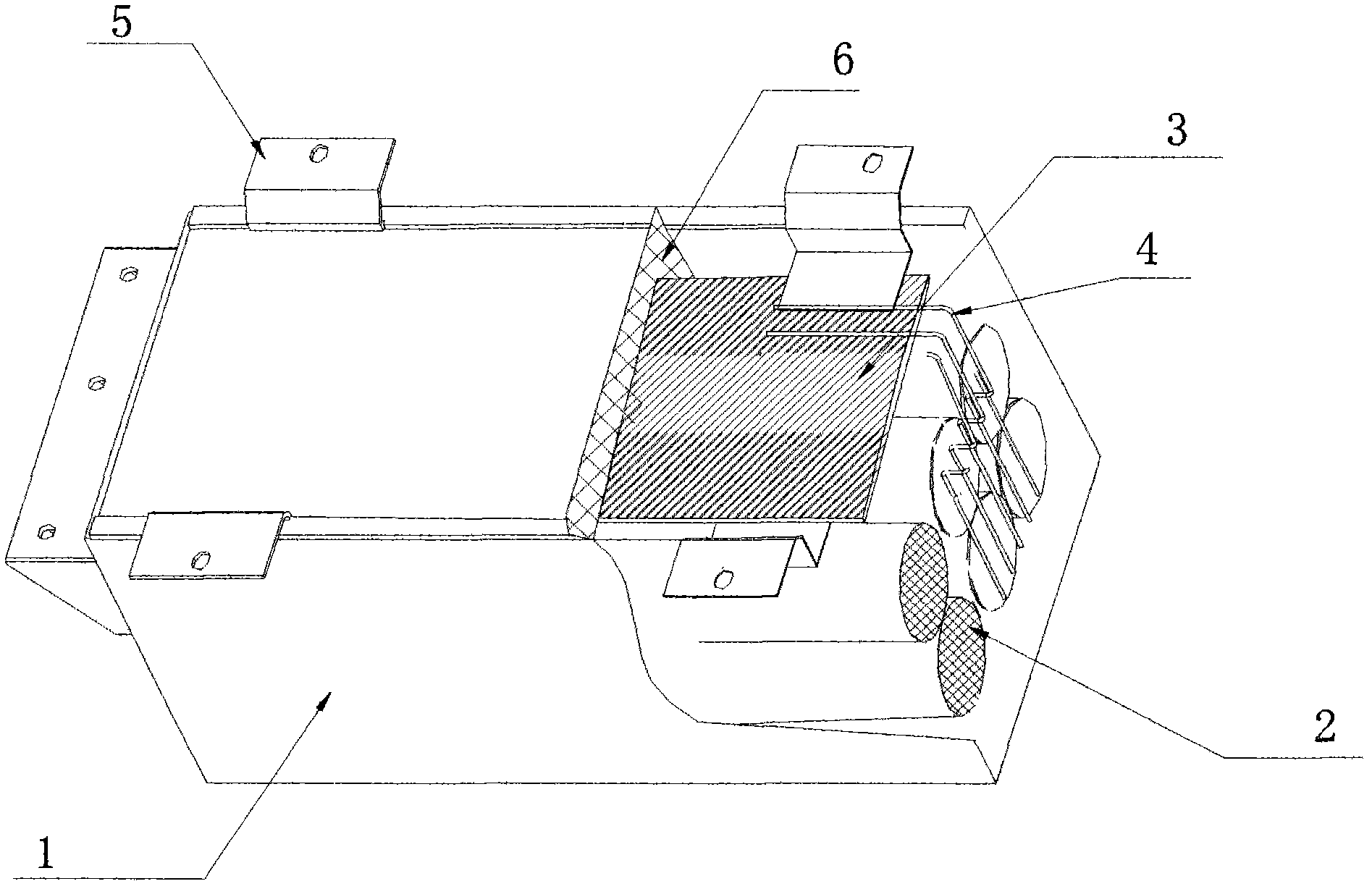

[0027] Embodiment 1: as attached figure 1 As shown, a DC support capacitor capable of effectively absorbing high-frequency harmonics includes a housing 1, and the housing 1 is provided with a core group 2 and a composite copper bar 3, and the core group 2 and the composite copper bar 3 are connected by a copper flexible wire 4, and the composite copper bar 3 is welded with two-pole lead-out ends 5, and the inside of the shell 1 is filled with potting material 6, which is used to fix the core group 2 and the Composite copper bar 3.

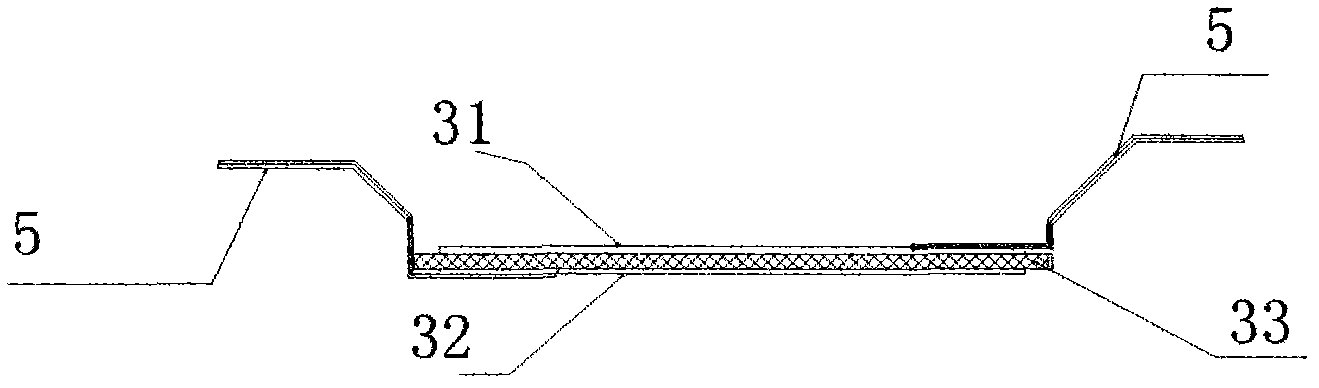

[0028] as attached figure 2 As shown, the composite copper bar 3 is composed of an upper copper plate 31, a lower copper plate 32, and an insulating layer 33 provided between the upper and lower copper plates.

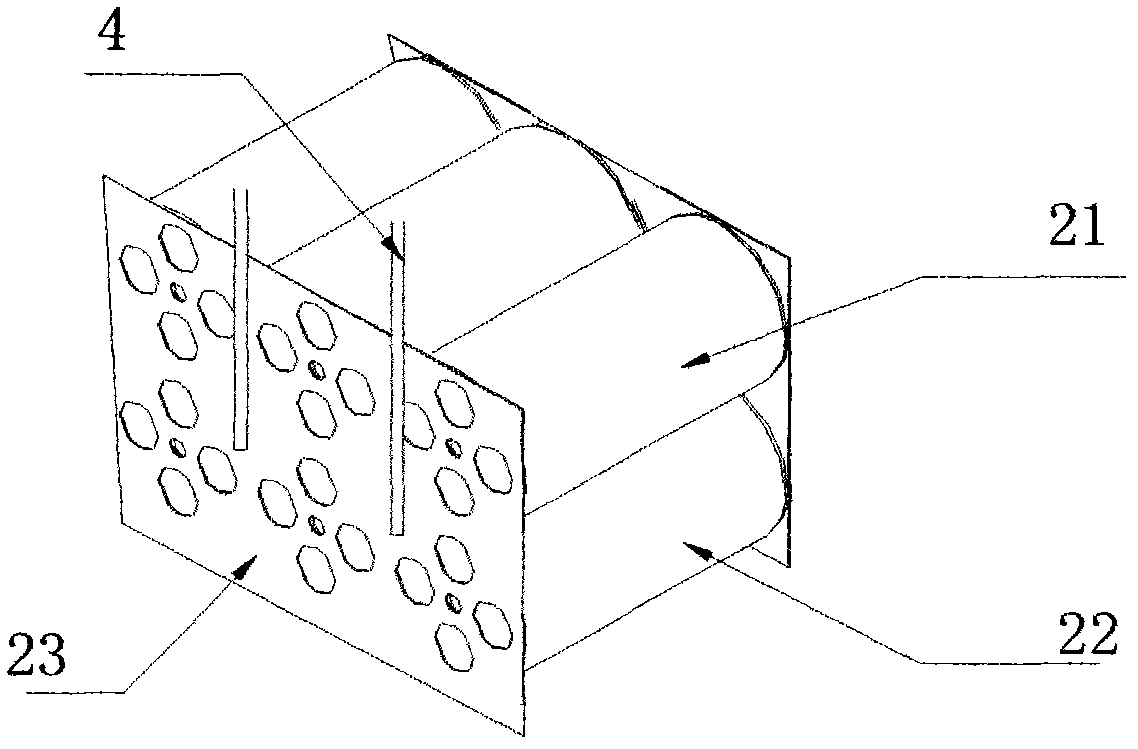

[0029] The core group 2 includes an upper absorption core group layer 21 and a lower DC filter core group layer 22 close to the two-pole lead-out ends 5, and the upper layer absorption core group 21 and the lower DC filter core group lay...

Embodiment 2

[0031] Embodiment 2: as attached Figure 4 And attached Figure 5 As shown, the lead ends 5 of the two poles are nuts and bolts, which are respectively the upper copper plate 31 and the lower copper plate 32 on both sides of the insulation layer 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com