White solid-state laser

A solid-state laser, laser array technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of increasing production costs, increasing production steps, reducing production efficiency, etc., achieving long working life, easy miniaturization, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

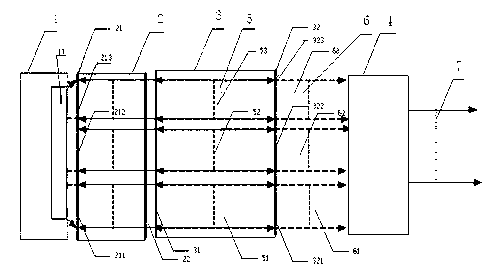

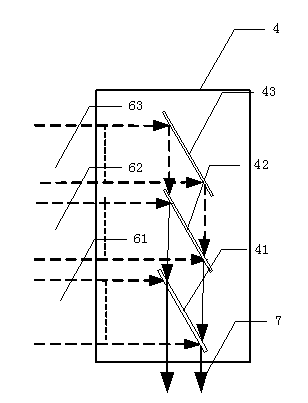

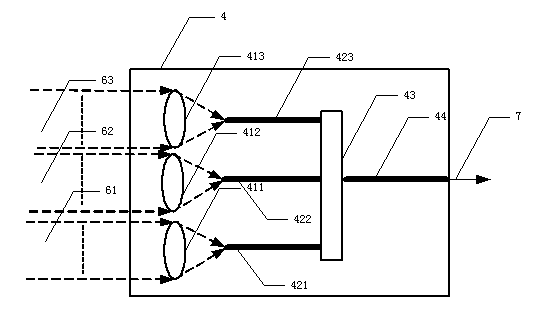

[0026] Such as figure 1 , 2 , 3 is an embodiment of a white light solid-state laser, which is composed of a semiconductor laser array 1, a laser crystal 2, a nonlinear crystal 3 and an optical system 4; the laser crystal 2 and the nonlinear crystal 3 form the resonance of the fundamental frequency light 5 cavity; the laser crystal 2 has a first end face 21 of the laser crystal and a second end face 22 of the laser crystal, wherein the first end face 21 of the laser crystal and the second end face 32 of the nonlinear crystal are directly coated with a film system, respectively constituting the fundamental frequency light 5 The cavity mirror of the resonant cavity; the nonlinear crystal 3 is a periodically polarized nonlinear crystal; the semiconductor laser array 1 is a one-dimensional linear array, and the light-emitting surface 11 is close to the first end face 21 of the laser crystal; the laser crystal The first end surface 21 is divided into three units, respectively: A un...

Embodiment 2

[0028] Different from the above-mentioned embodiment 1, the duty ratio of the light-emitting surface 11 of the semiconductor laser array 1 is 1.5:1, the power of the light-emitting elements is 1.5W, and the interval between the light-emitting elements is 150 μm; there are 18 light-emitting elements.

Embodiment 3

[0030] The difference from the above-mentioned embodiment 1 is that the duty ratio of the light-emitting surface 11 of the semiconductor laser array 1 is 2:1, the power of the light-emitting elements is 1.8W, and the interval between the light-emitting elements is 200 μm; there are 15 light-emitting elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com