Mini-type combined type energy collector based on PVDF (Poly Vinyli Dene Fluoride) and preparation method

An energy harvester and composite technology, applied in the field of micro-electromechanical systems, can solve the problems of small current and low output power, and achieve the effects of simple preparation process, increased output power and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

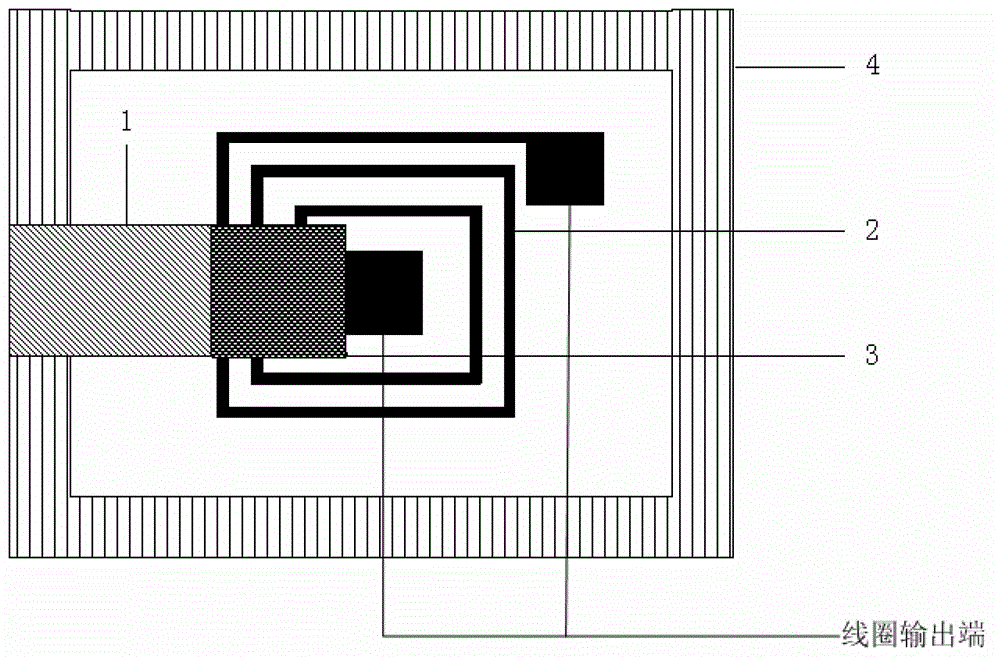

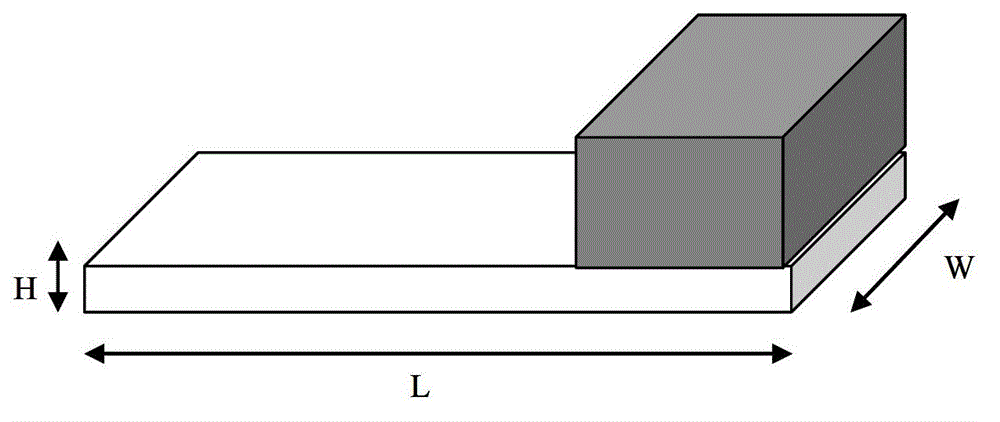

[0048] A piezoelectric and electromagnetic composite MEMS energy harvester, including a substrate, a PVDF piezoelectric film, a planar spiral coil 2, a PDMS mass block 3 containing magnetic nanoparticles, and a flexible support 4, i.e. a PDMS support frame, such as figure 1 shown. The PVDF piezoelectric film is made into a cantilever beam structure, and the substrate is deposited with a layer of SiO on the surface 2 composed of silicon wafers, the planar spiral coil 2 is electroplated on SiO 2 layer, the flexible support 4 is also located on the SiO 2 Layer, and located around the planar helical coil 2. The PVDF piezoelectric film is cut into a cantilever structure, and the PDMS mass block 3 containing magnetic nanoparticles is fixed on the free end of the PVDF piezoelectric cantilever 1, and the other end of the PVDF piezoelectric cantilever 1 is fixed on the flexible support 4, as figure 2 shown. The free end of the PVDF piezoelectric cantilever beam 1 is the output end...

Embodiment 2

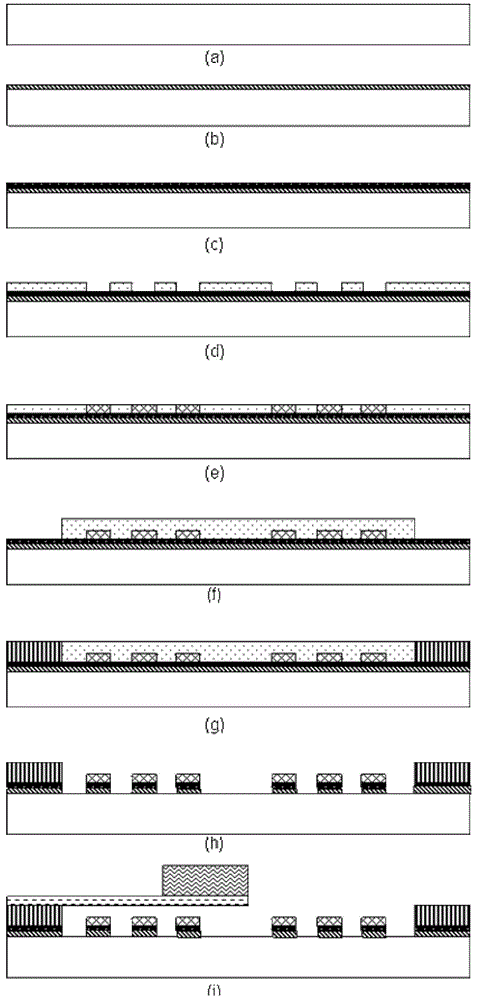

[0063] A preparation method of a piezoelectric and electromagnetic composite MEMS energy harvester, using a three-dimensional micromachining method combining bulk silicon and surface micromachining techniques, including a substrate, a PVDF piezoelectric film, a planar helical coil 2, and magnetic nanoparticles The PDMS mass block 3 also includes a vibration window 5, as shown in FIG. 6 . That is, the silicon is etched by bulk silicon micromachining technology to form the vibration window of the PVDF piezoelectric cantilever beam, and the planar spiral coil 2 is fabricated on the silicon chip by surface micromachining.

[0064] The manufacturing steps are roughly the same as those in Embodiment 1, except that after the planar spiral coil 2 is manufactured, the vibration window 5 is manufactured using wet etching technology instead of the flexible support 4 .

[0065] Step (3) is to make the vibration window, the process is as follows Figure 7 As shown, specifically:

[0066]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com