Dye-sensitized solar cell and dye-sensitized solar cell module

A solar cell and pigment sensitization technology, which is applied to solar cells, electrolytic capacitors, circuits, etc., can solve the problems of insufficient sealing structure, insufficient sealing structure of external connection terminals, and the inability to reliably prevent electrolytes, etc., to achieve prevention The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

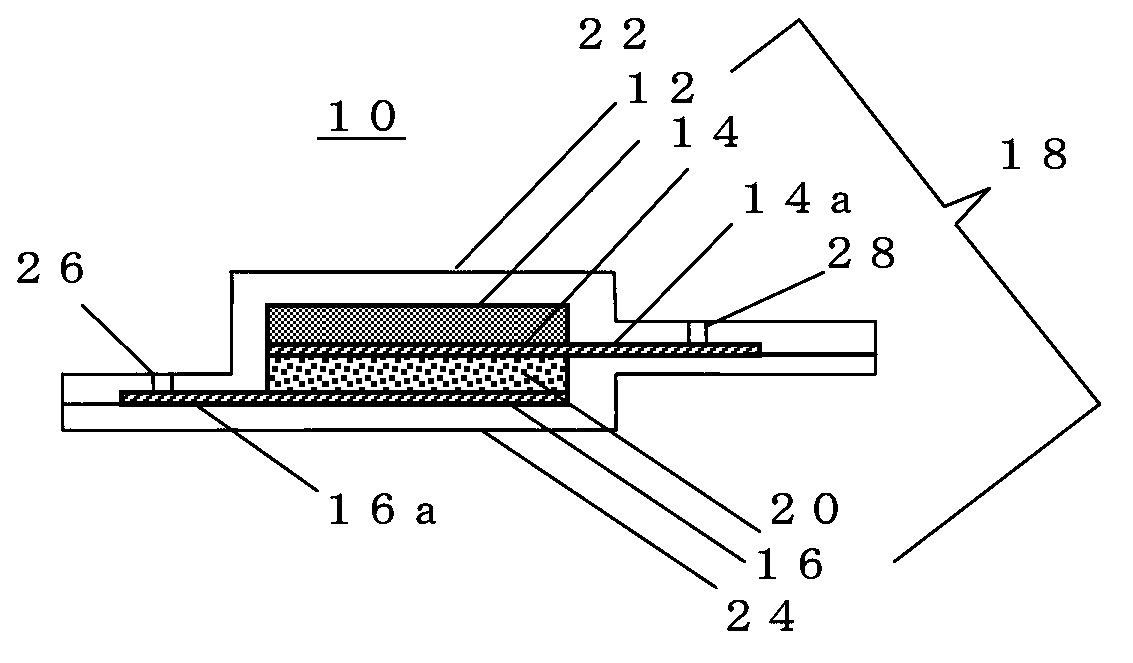

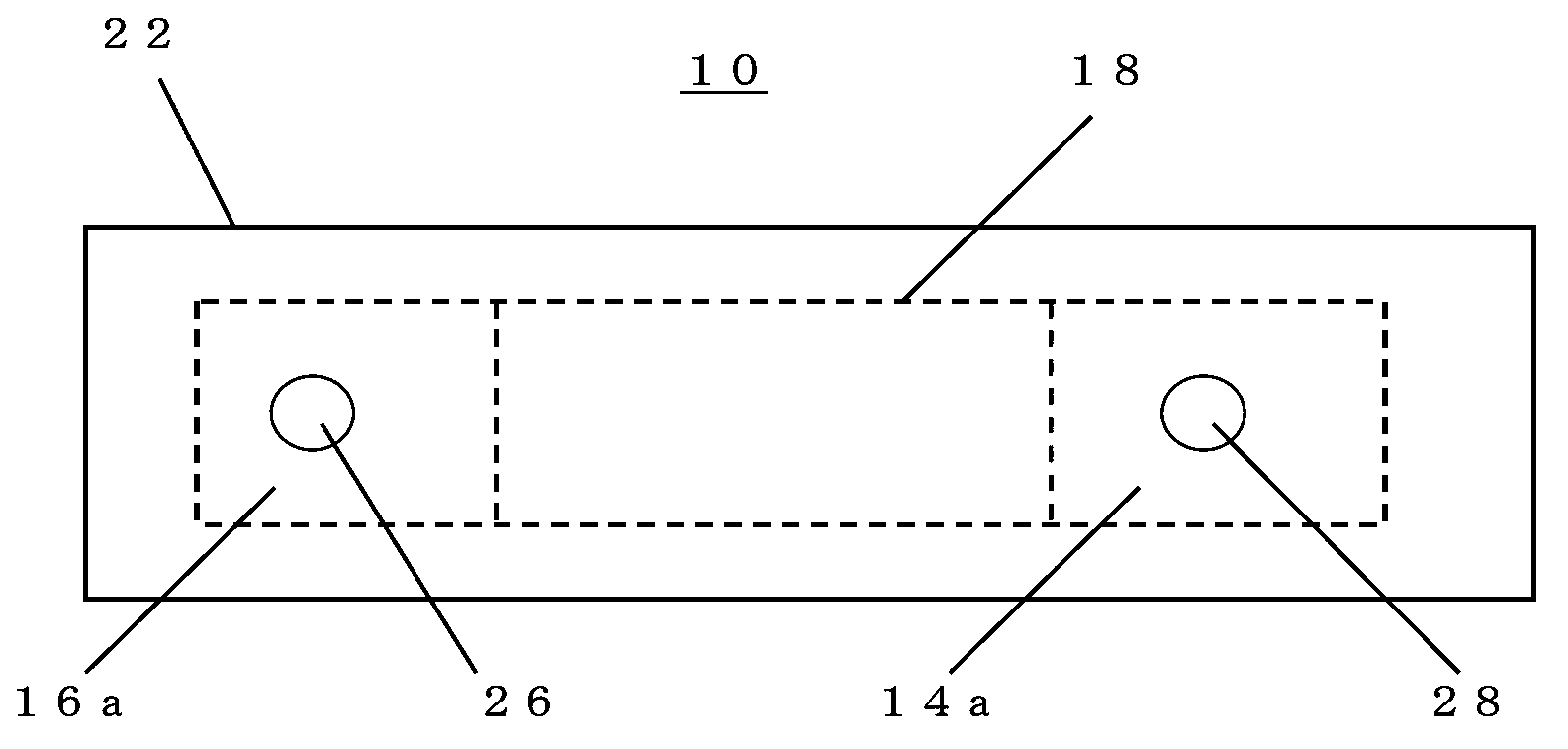

Embodiment 1)

[0138] Titanium dioxide paste (trade name Nanoxide D, manufactured by solaronix (ソラロニニクス)) is printed on a porous Ti plate (trade name Tiporous, manufactured by Osaka Titanium Industry Co., Ltd.) with a thickness of 100 μm in the range of 5 mm × 20 mm. Sinter in air at 400°C for 30 minutes. On the sintered titanium dioxide, the operation of printing and sintering the titanium dioxide paste was further repeated six times in total, and a 17 μm thick titanium dioxide layer was formed on one side of the porous Ti plate. At this time, the porous Ti plate was formed with a size of 9 mm×24 mm such that both ends were exposed 2 mm from the titanium dioxide layer of 5 mm×20 mm. The pore diameter distribution of the porous Ti plate was measured by the mercury intrusion method, and the results showed that the pore volume = 0.159cc / g (porosity = 40.1%), and the specific surface area = 5.6m 2 / g, average pore diameter = 8 μm (60% of the pore volume is 4-10 μm).

[0139] Next, the prepare...

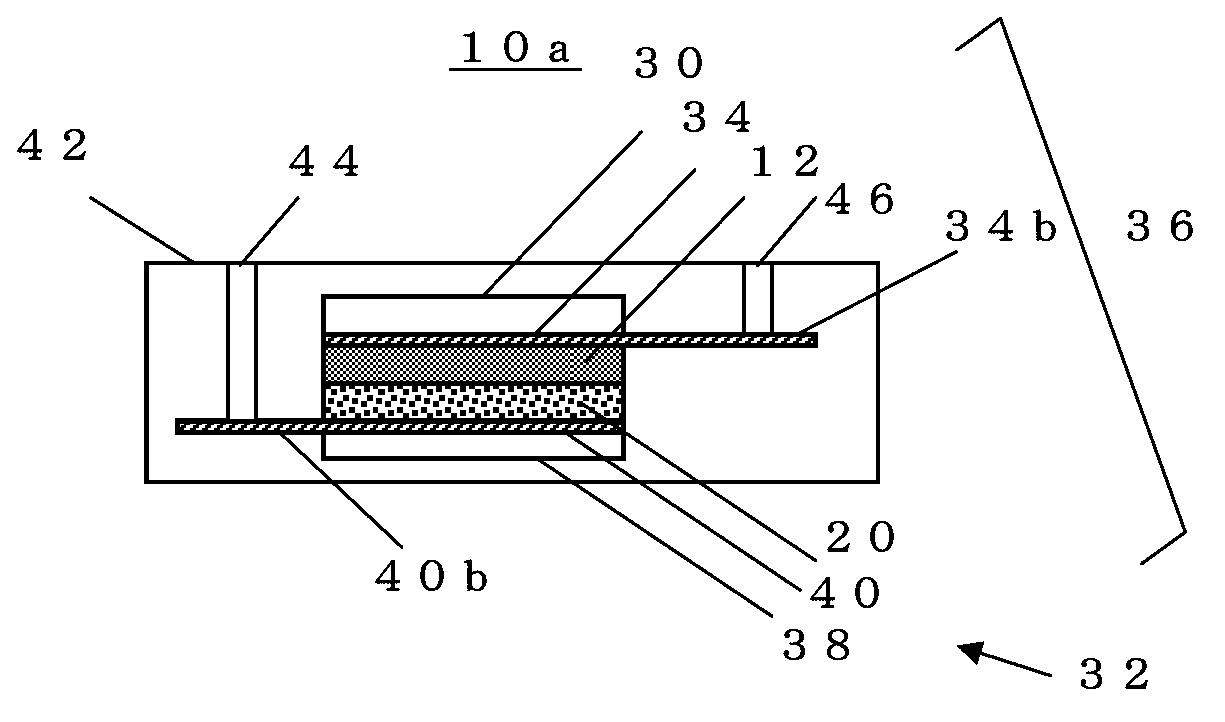

Embodiment 2)

[0144] Titanium dioxide paste (trade name Nanoxide D, manufactured by Solaronix Co., Ltd.) was printed on a porous Ti plate (trade name Tiporous, manufactured by Osaka Titanium Co., Ltd.) with a thickness of 100 μm in the range of 96 mm × 96 mm, and dried in air at 400 ° C. Sinter for 30 minutes. On the sintered titanium dioxide, the operation of printing and sintering the titanium dioxide paste was further repeated three times in total to form a 10 μm thick titanium dioxide layer on one side of the porous Ti plate. At this time, the porous Ti plate was formed in a size of 98 mm×96 mm such that only one side was exposed by 2 mm from the titanium dioxide layer of 96 mm×96 mm. The pore diameter distribution of the porous Ti plate was measured by the mercury intrusion method, and the results showed that the pore volume = 0.159cc / g (porosity = 40.1%), and the specific surface area = 5.6m 2 / g, average pore diameter = 8 μm (60% of the pore volume is 4-10 μm).

[0145] Next, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com