Preparation technology of biphasic bone and cartilage tissue engineering scaffold material

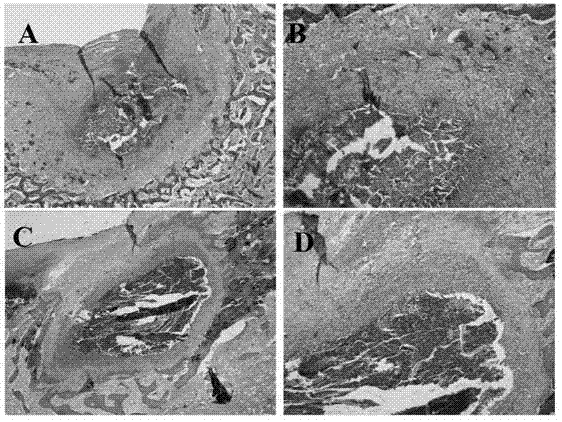

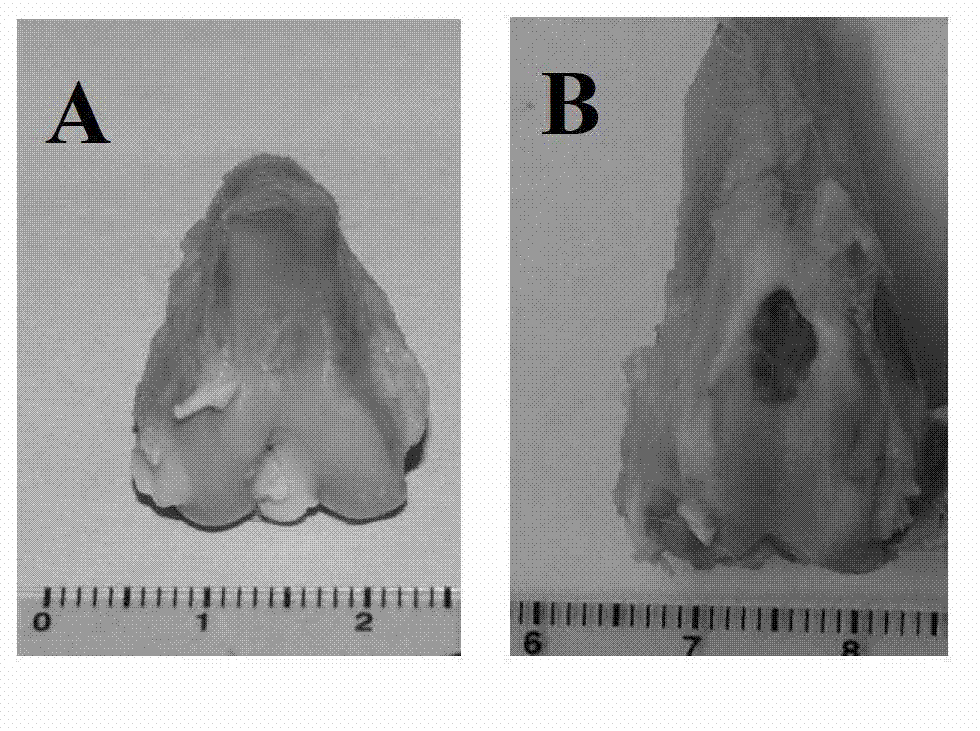

A tissue engineering scaffold and preparation process technology, applied in medical science, prosthesis, etc., can solve the problem that the scaffold microstructure does not consider the complex layered structure of natural tissue, and achieve uniform pore size distribution, good biocompatibility, and repair effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

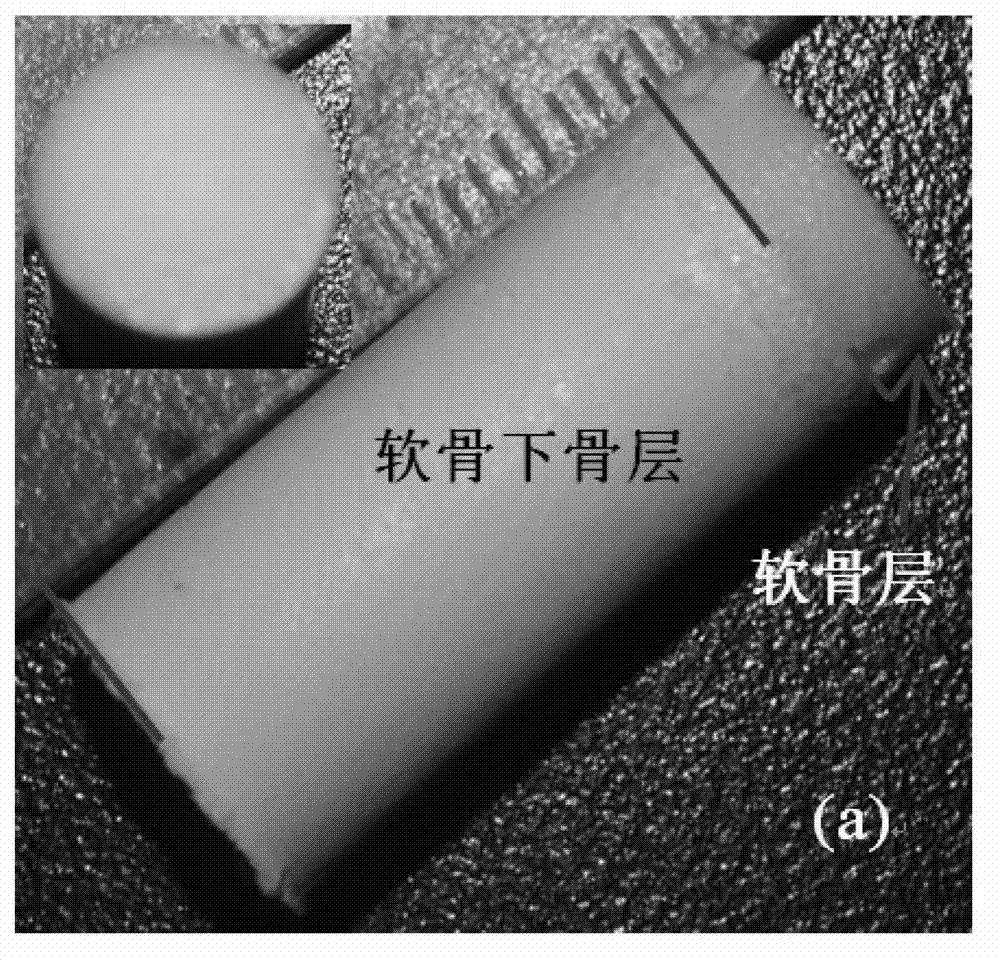

[0025] A preparation process for dual-phase osteochondral tissue engineering scaffold material, comprising the following steps:

[0026] Step 1: Add chitosan and collagen powder to the acetic acid solution with a mass concentration of 2%, mix and stir, mix the collagen and chitosan in any proportion, configure the ratio of the collagen and chitosan mixture to the acetic acid aqueous solution to be 2.1g: 100ml of the solution, stored in a 4°C refrigerator for later use;

[0027] Step 2: Dissolve polylactic acid (PLA) in 1,4-dioxane solvent, prepare a 6%wt PLA solution, take bone powder and add it to the PLA solution, the amount of bone powder added is the same as the quality of PLA powder, mix and stir Uniform, bone powder adopts nanocrystalline calcium phosphate collagen-based bone repair material;

[0028] Step 3, take a dry through-hole polytetrafluoroethylene mold, block the hole from one end of the mold with a polytetrafluoroethylene cylinder with the same diameter as the...

Embodiment 2

[0033] A preparation process for dual-phase osteochondral tissue engineering scaffold material, comprising the following steps:

[0034] Step 1, add chitosan and collagen powder to the acetic acid solution with a mass concentration of 2%, mix and stir, the collagen and chitosan are mixed in any proportion, and the ratio of the collagen and chitosan mixture to the aqueous acetic acid solution is 3.5g: 100ml of the solution, stored in a 4°C refrigerator for later use;

[0035] Step 2: Dissolve polylactic acid (PLA) in 1,4-dioxane solvent, prepare 8%wt PLA solution, take bone powder and add it to PLA solution, the amount of bone powder added is the same as the quality of PLA powder, mix and stir Uniform, bone powder adopts nanocrystalline calcium phosphate collagen-based bone repair material;

[0036] Step 3, take a dry through-hole polytetrafluoroethylene mold, block the hole from one end of the mold with a polytetrafluoroethylene cylinder with the same diameter as the through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com