Antifog polypropylene masterbatch material

An anti-fog masterbatch and polypropylene technology, applied in the field of polymer materials, can solve the problems of users not being able to see the products, easy to deteriorate and spoil, shorten the shelf life and shelf life of fresh products, achieve good fluidity, and avoid raw material dispersion Uneven, good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

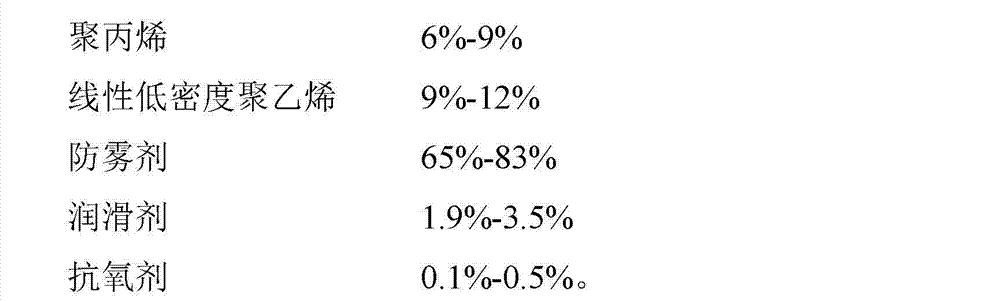

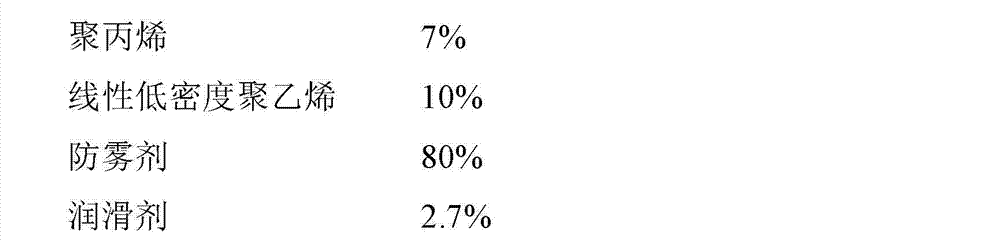

Embodiment 1

[0031] Weigh 60g of polypropylene, 90g of linear low-density polyethylene, 830g of anti-fog masterbatch, 19g of N,N-ethylene bisstearamide and 1g of antioxidant for thorough mixing, and add the mixed material to twin-screw extrusion In the hopper of the machine, the polypropylene anti-fog masterbatch is obtained through melt blending and extrusion granulation. Among them, the temperature of each heating zone of the screw machine is set as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 220°C, and the temperature of the head of the twin-screw machine is 240°C. ℃, the residence time is 3-4min, and the pressure is 19MPa.

[0032] The prepared anti-fog masterbatch is mixed with polypropylene in different contents, and after mixing evenly, it is added to a twin-screw machine, melted, extruded and granulated to obtain a polypropylene anti-fog masterbatc...

Embodiment 2

[0034] Weigh 90g of polypropylene, 120g of linear low-density polyethylene, 750g of anti-fog masterbatch, 35g of N,N-ethylene bisstearamide and 5g of antioxidant for full mixing, and add the mixed materials to twin-screw extrusion In the hopper of the machine, the polypropylene anti-fog masterbatch is obtained through melt blending and extrusion granulation. Among them, the temperature of each heating zone of the screw machine is set as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 220°C, and the temperature of the head of the twin-screw machine is 240°C. ℃, the residence time is 3-4min, and the pressure is 19MPa.

[0035] The prepared anti-fog masterbatch is mixed with polypropylene in different contents, and after mixing evenly, it is added to a twin-screw machine, melted, extruded and granulated to obtain a polypropylene anti-fog masterbatch ...

Embodiment 3

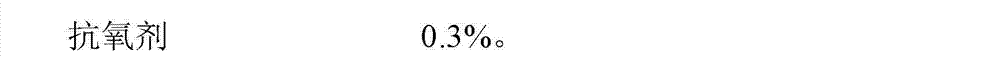

[0037] Weigh 75g of polypropylene, 105g of linear low-density polyethylene, 790g of anti-fog masterbatch, N, N-ethylene bisstearamide g and 3g of antioxidant to fully mix, and add the mixed material to twin-screw extrusion In the hopper of the machine, the polypropylene anti-fog masterbatch is obtained through melt blending and extrusion granulation. Among them, the temperature of each heating zone of the screw machine is set as follows: the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 220°C, and the temperature of the head of the twin-screw machine is 240°C. ℃, the residence time is 3-4min, and the pressure is 19MPa.

[0038] The prepared anti-fog masterbatch is mixed with polypropylene in different contents, and after mixing evenly, it is added to a twin-screw machine, melted, extruded and granulated to obtain a polypropylene anti-fog masterbatch material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com