Metal surface treatment agent and metal material obtained through processing with same

A metal surface treatment and base material technology, applied in the field of metal surface treatment agent and the metal material obtained by using the treatment agent, can solve the problems of metal surface corrosion, film deterioration, adhesion reduction, etc., and reduce the treatment cost. Effects of cost, space saving, and stable adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

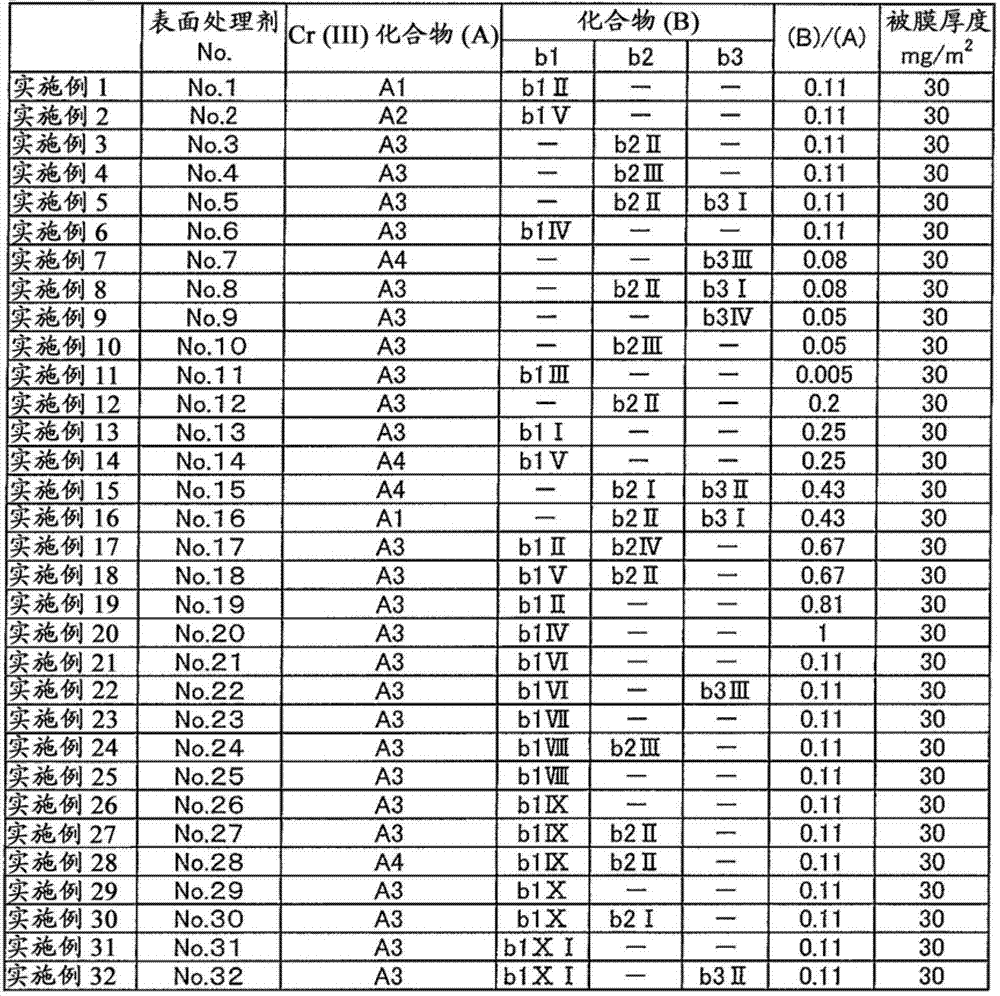

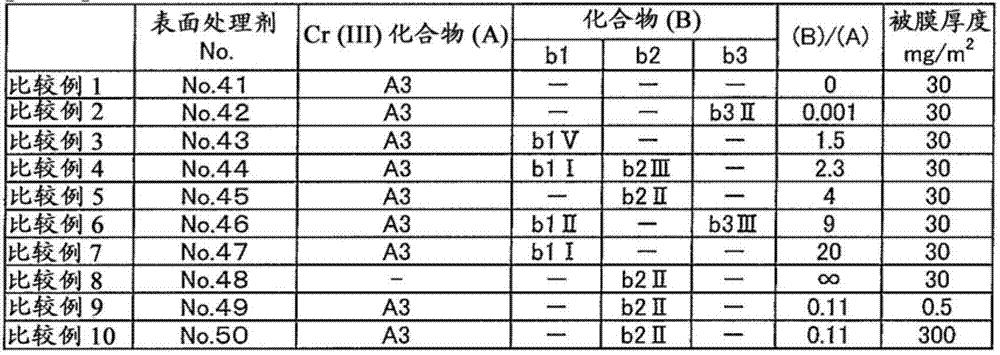

Embodiment 1~32 and comparative example 1~10

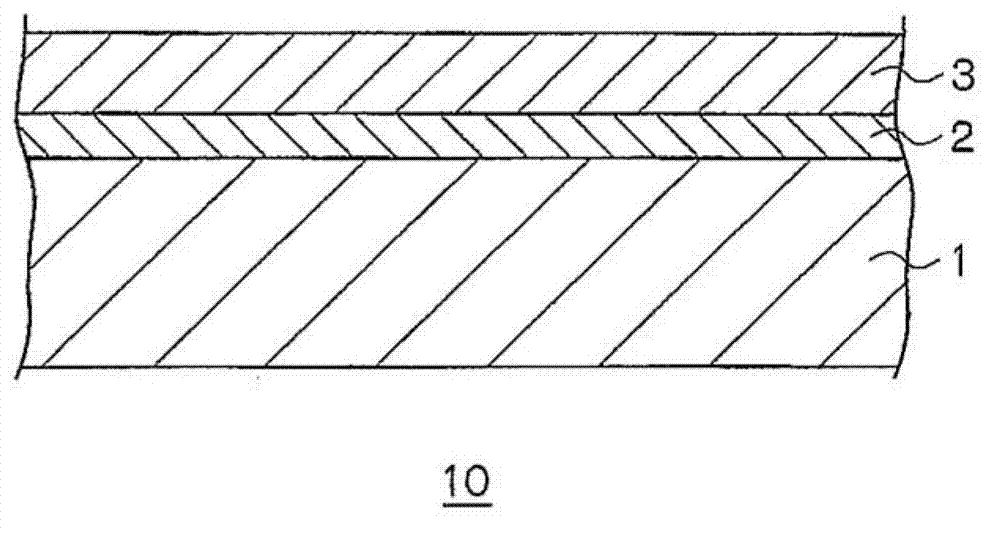

[0149] A stainless steel plate (SUS304, plate thickness 0.3 mm) was spray-degreased at 65° C. for 1 minute with a 3% aqueous solution of Fine cleaner E359 (alkali degreasing agent manufactured by Nihon Parkerizing Co., Ltd.), and then washed with water to clean the surface. Next, in order to evaporate the water|moisture content of the surface of a stainless steel plate, it dried with a drier. Utilize the rod coating method that the metal surface treatment agent of the embodiment 1~32 shown in table 1 and table 2 and comparative example 1~10 is coated on the stainless steel plate surface through degreasing cleaning, and in hot air circulation type drying oven at 200 °C for 1 minute to form a surface treatment film with a given film thickness on the surface of the stainless steel plate. On a stainless steel plate with a surface treatment film formed, heat-laminate a polyester film (film thickness 16 μm) at 250°C for 5 seconds (reaching plate temperature is 180°C), and make the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com