Cathode isolating device for organic light emitting device and manufacturing method for cathode isolating device

A technology for organic light-emitting devices and isolation devices, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problem of damage to organic functional layers or cathode materials, it is difficult to obtain high resolution, and it is not suitable for organic light-emitting devices. Cathode pattern and other problems, to save process steps, improve resolution, prevent cross effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing a cathode isolation device for an organic light-emitting device, comprising the following steps:

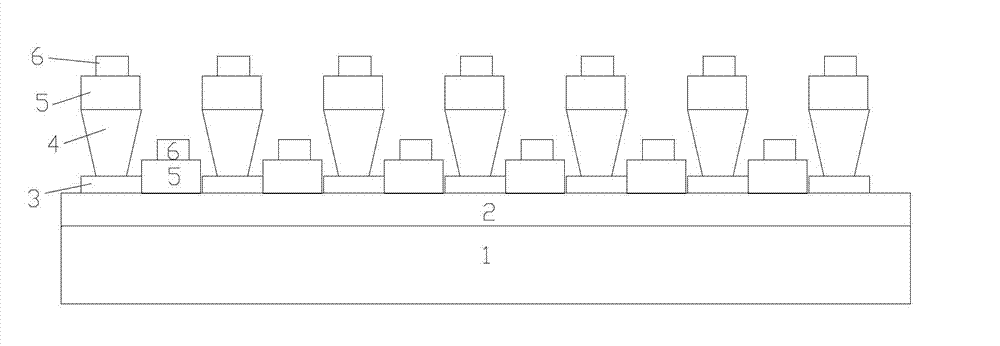

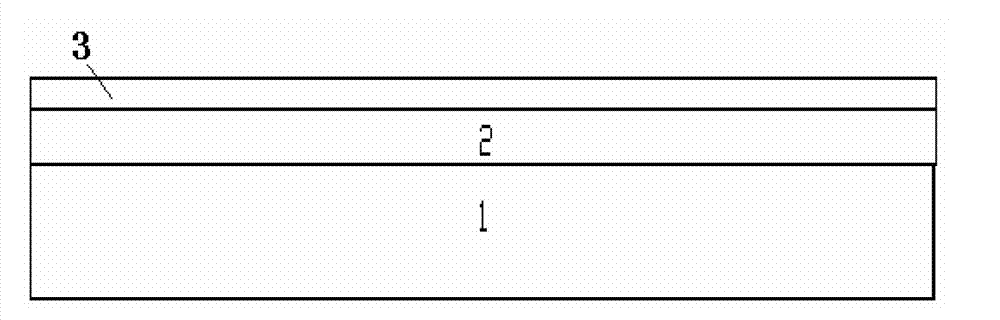

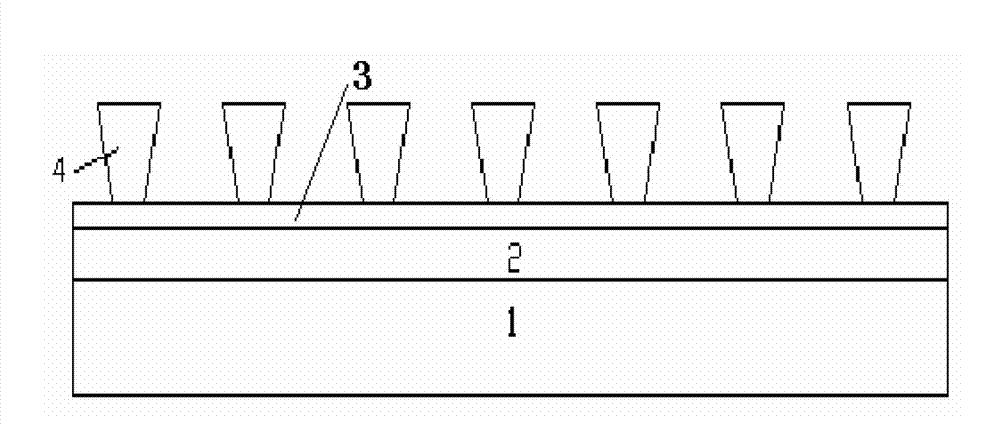

[0025] Such as figure 2 , 3 , 4, to make the cathode isolating device, first the ITO anode layer 2 on the glass substrate 1 is etched into the required pattern, and the cathode isolating device is made on the etched ITO anode layer 2, specifically coating The first layer of water-soluble insulating medium layer 3, after sintering, print the photosensitive insulating medium layer 4 on this layer, and then use the film graphic model as a mask to carry out photoetching to the photosensitive insulating medium layer 4, so that the photosensitive insulating medium Layer 4 forms an isolated band-like distribution with an inverted trapezoidal cross-section, and then uses the inverted trapezoidal pattern as a mask to wet-etch the water-soluble insulating medium to form an isolated band-like distribution with a rectangular cross-section, and finally stea...

Embodiment 2

[0031] After the glass substrate 1 is ultrasonically cleaned with acetone, the manufacturing process is carried out in the following steps:

[0032] 1. Etching the ITO anode layer 2 on the glass substrate 1 into the required pattern;

[0033] 2. The water-soluble insulating medium layer 3 is printed and dried (130°C, under the atmosphere, 15min);

[0034] 4. Sintering of the water-soluble insulating dielectric layer 3 (580°C, 20min in the atmosphere);

[0035] 5. The photosensitive insulating medium layer 4 is printed for the first time, and dried (100°C, under the atmosphere, for 15 minutes);

[0036] 6. The photosensitive insulating medium layer 4 is printed for the second time, and dried (100°C, under the atmosphere, for 15 minutes);

[0037] 7. Photolithography is performed on the photosensitive insulating medium layer 4 by using the film graphic model as a mask, the exposure energy is 800 mJ, and the developing solution is 0.3% sodium carbonate solution.

[0038] 8. Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com