Flue gas desulfurization device and desulfurization method by magnesium oxide process

A desulfurization equipment, magnesium oxide technology, applied in chemical instruments and methods, separation methods, magnesium sulfate and other directions, can solve problems such as consumption, low regeneration rate of magnesium oxide, and reduced desulfurization efficiency, so as to overcome the complexity of desulfurization process and avoid scaling and siltation, space saving and investment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

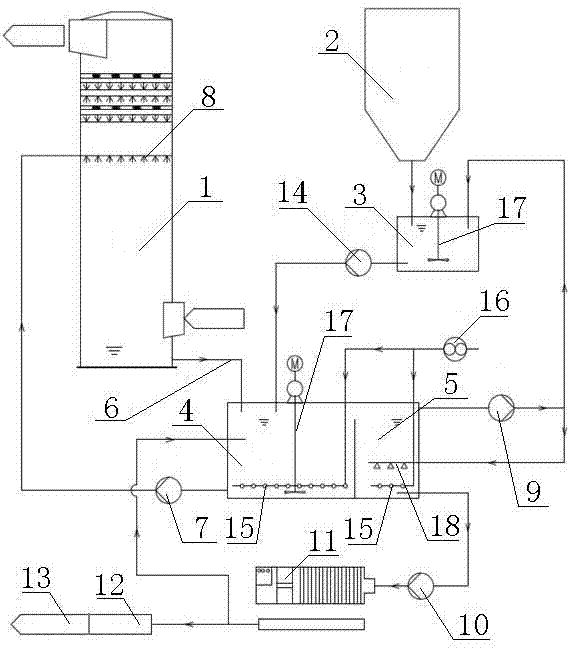

[0034] This embodiment comprises absorption tower 1 and magnesia powder bin 2, and magnesia powder bin 2 is connected with pulping pond 3, circulation pond 4 and sedimentation pond 5 successively, and the bottom of absorption tower 1 is provided with the pipeline 6 leading to circulation pond 4, The circulation tank 4 is connected to the spray layer 8 on the upper part of the absorption tower 1 through the absorption tower circulation pump 7, the top of the sedimentation tank 5 is connected to the pulping tank 3 through the clear liquid return pump 9, and the bottom of the sedimentation tank 5 is connected to the slurry tank 5 through the slag discharge pump 10. The plate and frame filter press 11 is connected, and the bottom of the plate and frame filter press 11 is connected with the circulation pool 4 and the waste water treatment equipment 12 or the magnesium sulfate heptahydrate preparation equipment 13 respectively. The pulping tank 3 is connected to the circulation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com