Corrosion-inhibition anti-coking agent for furfural refining device

A technology of furfural refining and coking inhibitor, which is applied in the fields of treatment equipment corrosion/fouling inhibition, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problems of not being able to prevent furfural oxidation, not being able to neutralize furfural oxides, etc., and achieve good corrosion inhibition performance , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

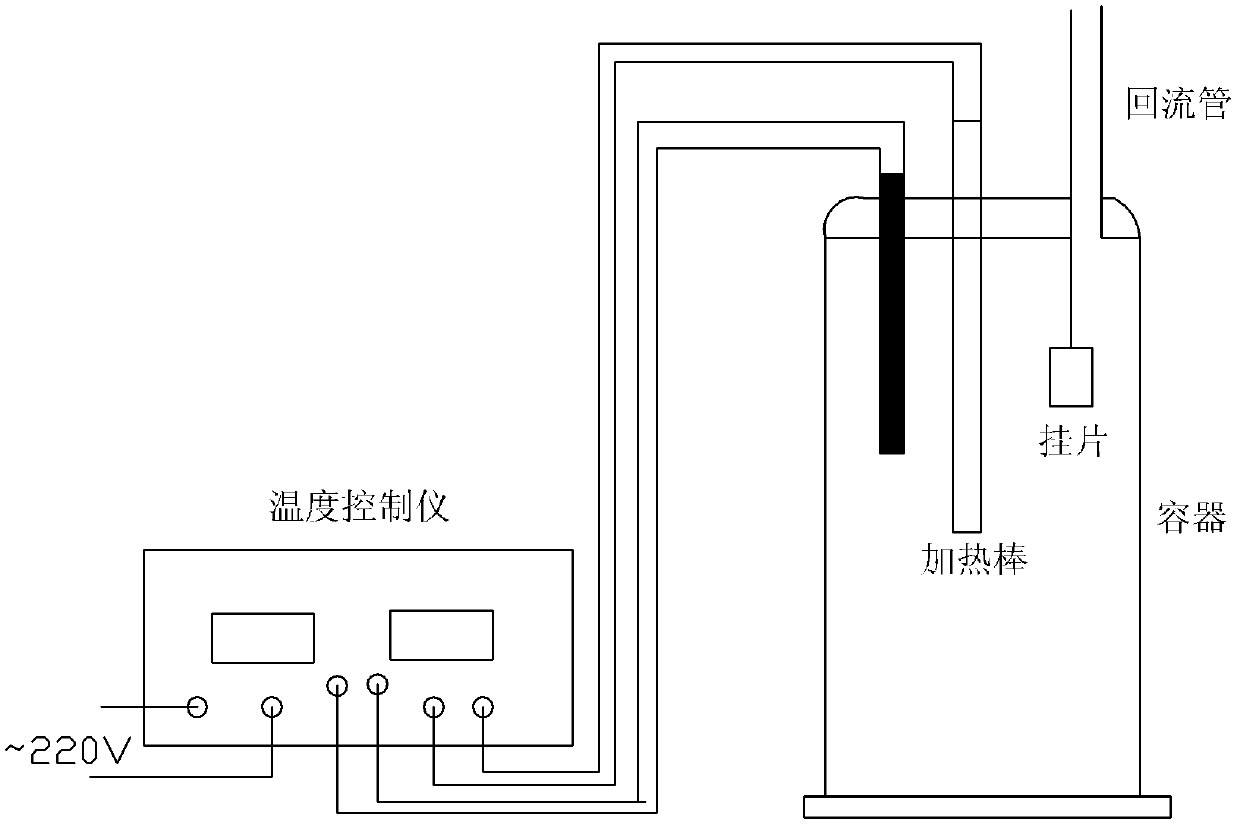

Image

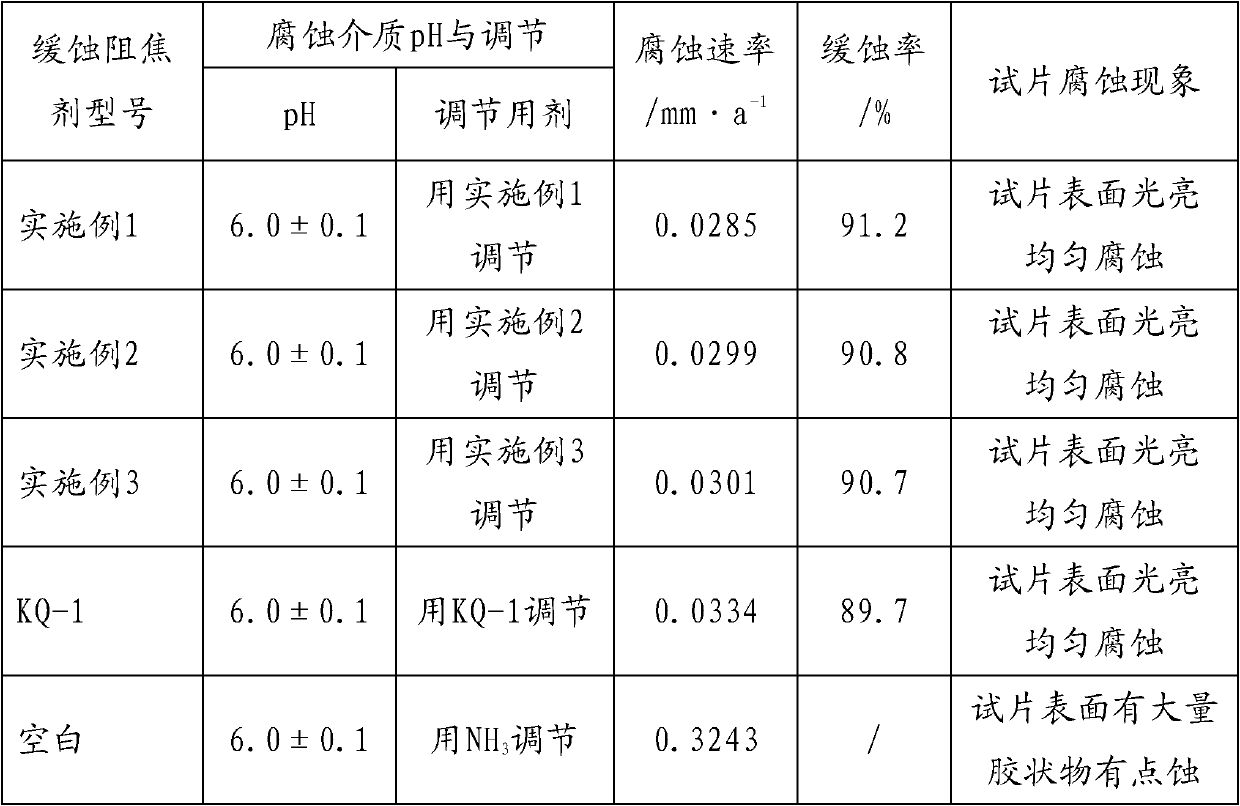

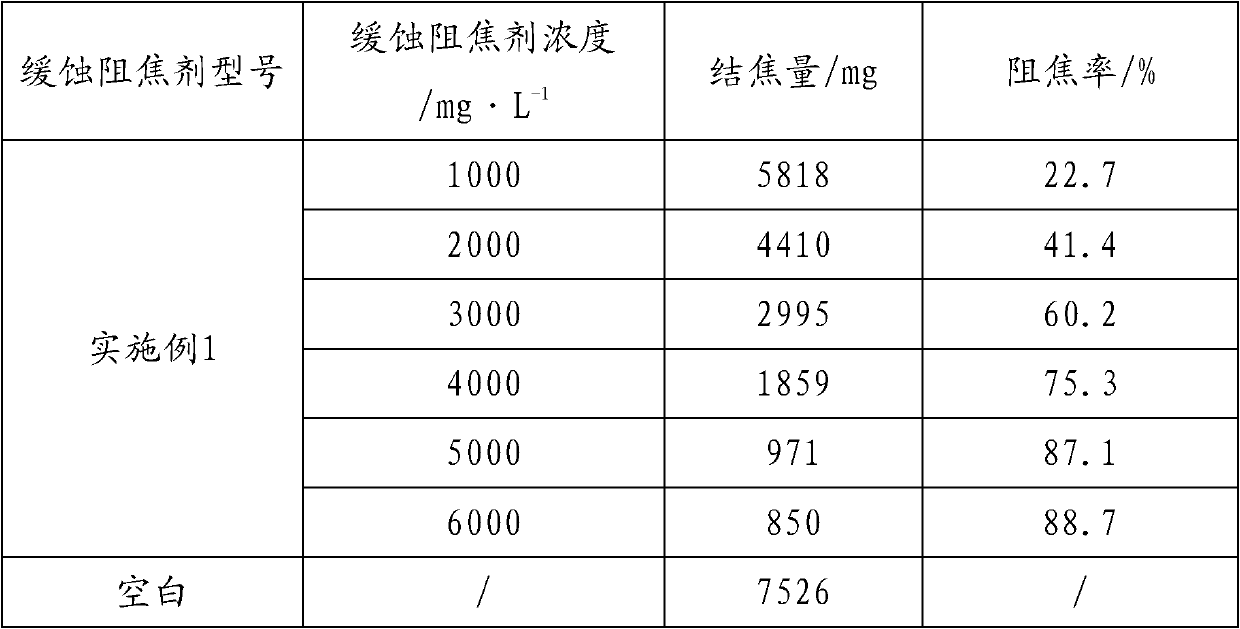

Examples

Embodiment 1

[0038] In this implementation, a corrosion and coking inhibitor for furfural refining equipment is provided, and its composition and weight percentage are:

[0039] Dispersed component 3%;

[0040] Neutral organic amines 9%;

[0041] Water-soluble imidazoline compounds 8%;

[0042] acetylenic alcohols 2%;

[0043] Nitrogen-containing adsorption type corrosion inhibitor compounds 10%;

[0044] Cyclic amine corrosion inhibitor 11%;

[0045] Amine antioxidant 5%;

[0046] Compounding solvent 52%.

[0047] In this embodiment, the dispersing component is polymaleic anhydride in organic carboxylic acid polymers; the neutral organic amines are ethylenediamine in polyethylene polyamines; the water-soluble imidazoline The compound is imidazoline naphthenate; the acetylenic alcohol compound is propynyl alcohol; the nitrogen-containing adsorption type corrosion inhibitor compound is benzotriazole; the cyclic amine corrosion inhibitor is cyclic amine The methylcyclopentadiamine; Th...

Embodiment 2

[0052] In this implementation, a corrosion and coking inhibitor for furfural refining equipment is provided, and its composition and weight percentage are:

[0053] Dispersion component 2%;

[0054] Neutral organic amines 10%;

[0055] Water-soluble imidazoline compounds 10%;

[0056] acetylenic alcohols 3%;

[0057] Nitrogen-containing adsorption type corrosion inhibitor compounds 9%;

[0058] Cyclic amine corrosion inhibitor 10%;

[0059]Amine antioxidant 7%;

[0060] Compound solvent 49%.

[0061] In this embodiment, the dispersing component is polyacrylic acid in organic carboxylic acid polymer; the neutral organic amine is monoethanolamine in alcohol amine; the water-soluble imidazoline compound is naphthenic acid imidazoline; the acetylenic alcohol compound is propynyl alcohol; the nitrogen-containing adsorption type corrosion inhibitor compound is urotropine; the cyclic amine corrosion inhibitor is o-phenylenediamine in aniline; The amine antioxidant is N,N-dibut...

Embodiment 3

[0065] In this implementation, a corrosion and coking inhibitor for furfural refining equipment is provided, and its composition and weight percentage are:

[0066] Dispersion component 2.5%;

[0067] Neutral organic amines 7%;

[0068] Water-soluble imidazoline compounds 15%;

[0069] acetylenic alcohols 3%;

[0070] Nitrogen-containing adsorption type corrosion inhibitor compounds 8%;

[0071] Cyclic amine corrosion inhibitor 12%;

[0072] Amine antioxidant 5%;

[0073] Compound solvent 47.5%.

[0074] In this embodiment, the dispersing component is polymaleic anhydride in organic carboxylic acid polymers; the neutral organic amines are diethylenetriamine in polyethylene polyamines; the water-soluble imidazole The morphine compound is imidazoline naphthenate; the acetylenic alcohol compound is butynediol dipropoxy ether in butynyl alcohol; the nitrogen-containing adsorption type corrosion inhibitor compound is urotropine; The cyclic amine corrosion inhibitor is p-phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com