Furnace building method of intermediate-frequency induction furnace for copper alloy smelting

An induction furnace and copper alloy technology, which is applied in the field of smelting equipment, can solve the problems of thickening the melting temperature of quartz sand, increasing the temperature difference between inside and outside, and cracking of graphite crucible, so as to prolong the effective service life, reduce production cracks, and lower the melting temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

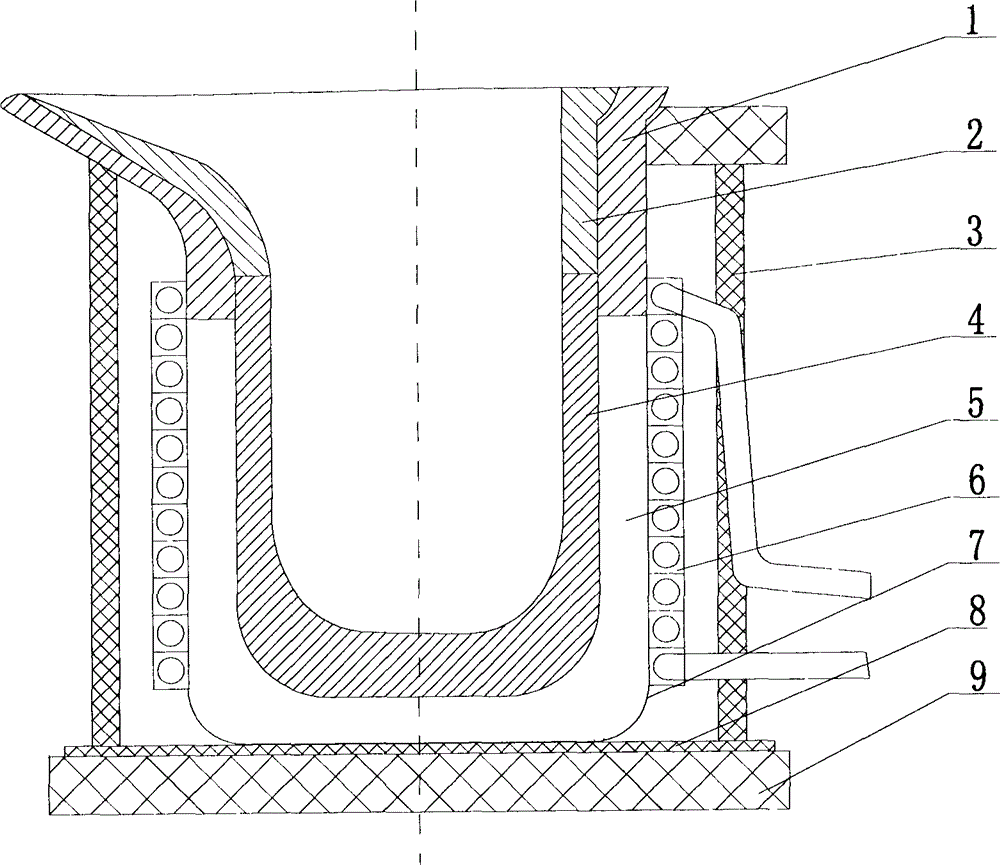

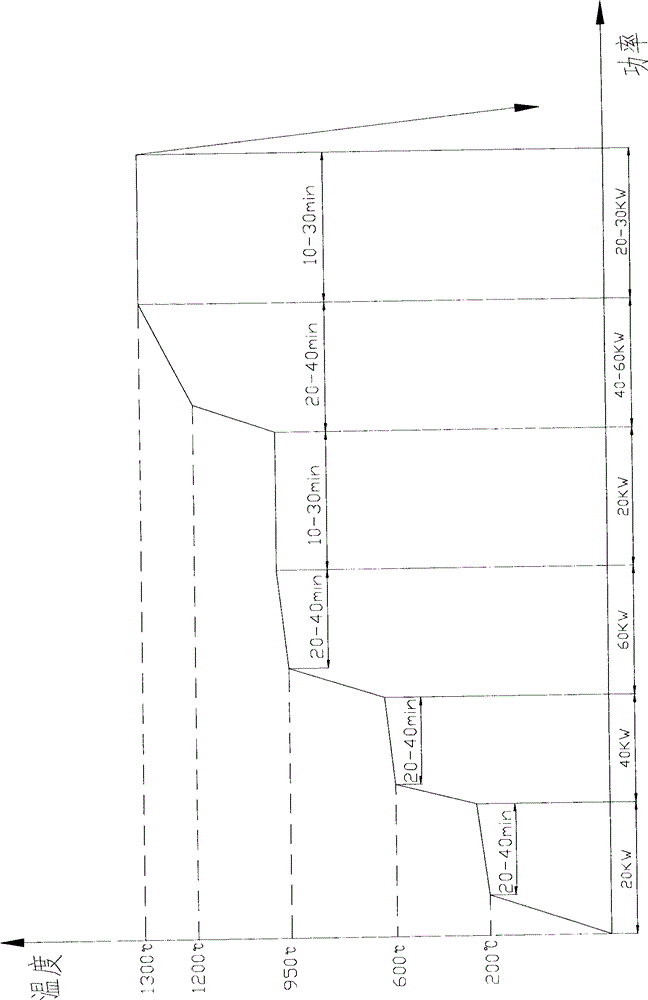

[0019] The method for building a medium-frequency induction furnace for smelting copper alloys of the present invention,

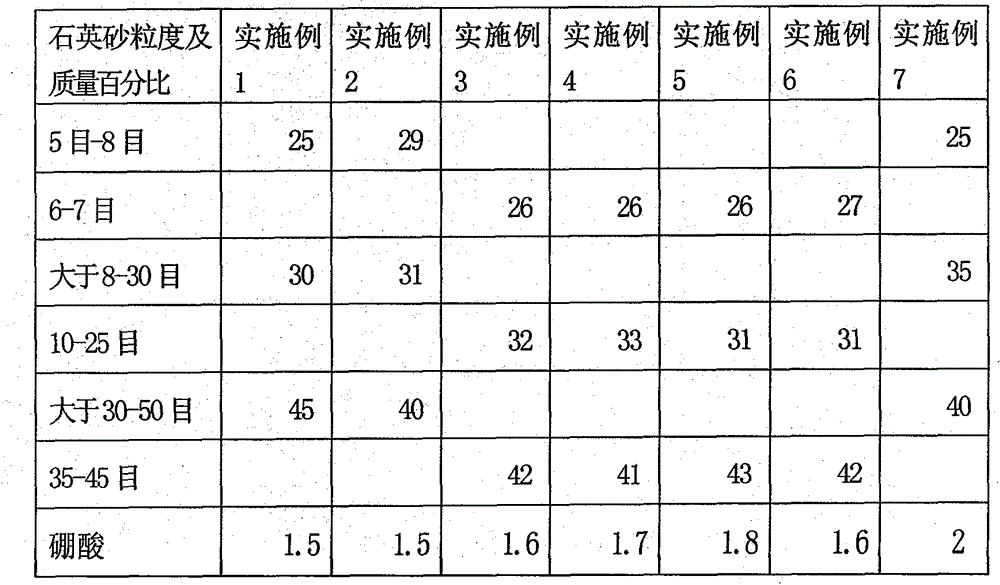

[0020] (1) Mix 25-30% quartz sand with a particle size of 5-8 mesh, 30-35% quartz sand with a particle size larger than 8-30 mesh, and 40-45% quartz sand with a particle size larger than 30-50 mesh with boric acid to prepare a furnace External lining material, wherein the proportion of quartz sand and boric acid is 100: (1.5-2) by mass, and the boric acid is industrial boric acid. By changing the particle size and proportion of quartz sand and the consumption of boric acid, the furnace The outer lining has a better density. The quartz sand of the furnace outer lining material in the present invention includes 26-27% quartz sand of 6-7 mesh, 31-33% quartz sand with a particle size of 10-25 mesh and 35-45% of the particle size. The purpose is 41-43% quartz sand, and the proportion of quartz sand and boric acid is 100: (1.6-1.8) by mass.

[0021] The specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com