Physical fatigue relieving nutrient liquid and preparation method thereof

A technology for relieving physical fatigue and nutrient solution, applied in food preparation, application, food science, etc., can solve the problems of long cycle and unfavorable professional athletes to improve their competitive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

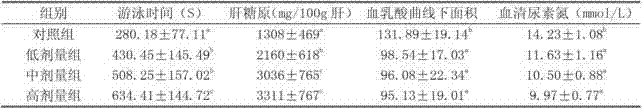

Examples

Embodiment 1

[0045] 1. Preparation of Peanut Polypeptides

[0046] Weigh a certain amount of peanut meal, add water according to the weight ratio of material to liquid 1:8, soak at room temperature, fully swell, homogenize with a high-speed dispersing homogenizer, and then extract in a constant temperature water bath at 40°C and adjust continuously while stirring. pH to 8.0. After leaching for 2 hours, centrifuge (3000r / min) for 10min, collect the supernatant, then carry out a second leaching (under the same conditions), combine the supernatant to adjust the pH value to 4.5, and then centrifuge (3000r / min) for 15min, take precipitation.

[0047] Weigh an appropriate amount of peanut protein precipitate, add water at a weight ratio of 1:5, and then fully mix in a high-speed dispersing homogenizer, preheat at 80°C for 10 minutes, and when it is lowered to 50°C, the concentration ratio of alkaline protease to substrate is 3%. Add alkaline protease for constant temperature enzymolysis. Durin...

Embodiment 2

[0059] 1. Preparation of Peanut Polypeptides

[0060] Weigh a certain amount of peanut meal, add water according to the weight ratio of material to liquid 1:12, soak at room temperature, fully swell, homogenize with a high-speed dispersing homogenizer, and then extract in a constant temperature water bath at 50°C and adjust continuously while stirring. pH to 9.5. After leaching for 2 hours, centrifuge (3000r / min) for 10min, collect the supernatant, then carry out a second leaching (under the same conditions), combine the supernatant to adjust the pH value to 4.5, and then centrifuge (3000r / min) for 15min, take precipitation.

[0061] Weigh an appropriate amount of peanut protein precipitate, add water at a weight ratio of 1:7.5, and mix thoroughly in a high-speed dispersing homogenizer, preheat at 80°C for 10 minutes, and when the concentration drops to 60°C, the concentration ratio of alkaline protease to substrate is 4.5%. Add alkaline protease for constant temperature enz...

Embodiment 3

[0073] 1. Preparation of Peanut Polypeptides

[0074] Weigh a certain amount of peanut meal, add water according to the weight ratio of material to liquid 1:15, soak at room temperature, fully swell, homogenize with a high-speed dispersing homogenizer, and then extract in a constant temperature water bath at 50°C and adjust continuously while stirring. pH to 11. After leaching for 2 hours, centrifuge (3000r / min) for 10min, collect the supernatant, then carry out a second leaching (under the same conditions), combine the supernatant to adjust the pH value to 4.5, and then centrifuge (3000r / min) for 15min, take precipitation.

[0075] Weigh an appropriate amount of peanut protein precipitate, add water at a weight ratio of 1:10, and mix thoroughly in a high-speed dispersing homogenizer, preheat at 80°C for 10 minutes, and when it drops to 70°C, the concentration ratio of alkaline protease to substrate is 6%. Add alkaline protease for constant temperature enzymolysis. During th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com