Method for eliminating acidity of external surface of ZSM-5 molecular sieve catalyst

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as affecting catalyst activity and small molecular size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

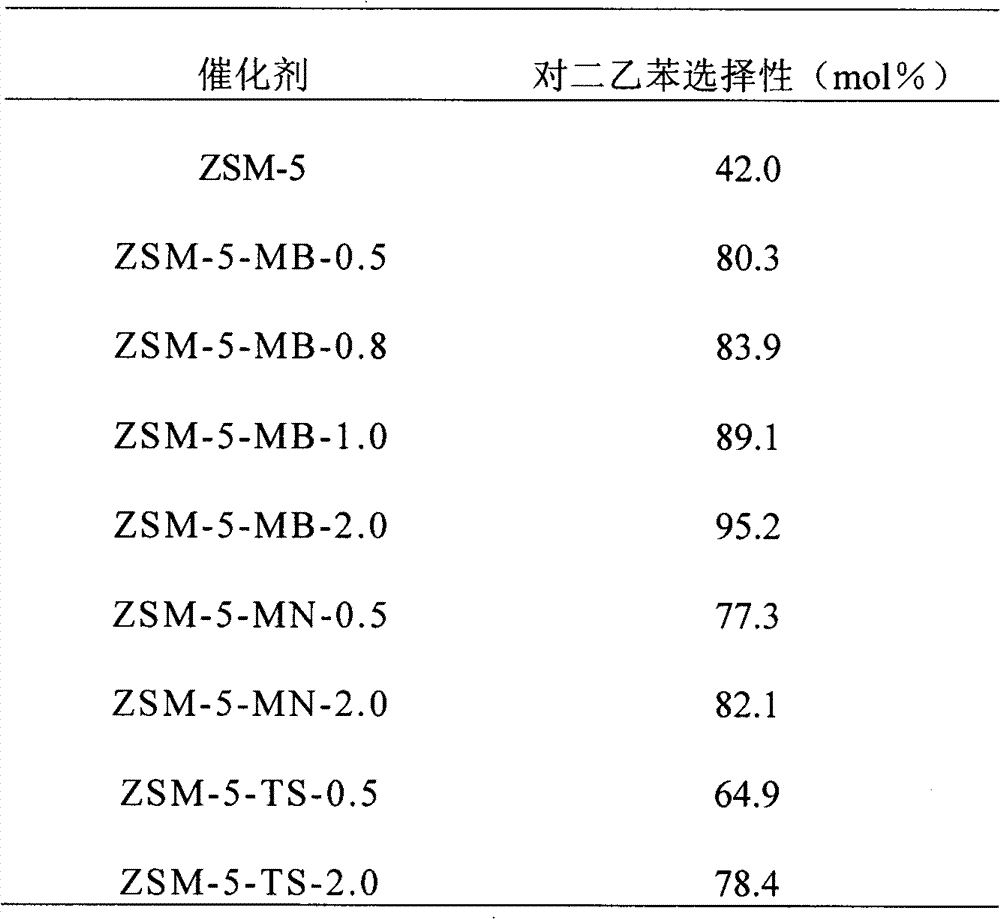

[0009] Embodiment 1: Grind off the oxides on the surface of the magnesium strip with sandpaper to reveal a bright metallic color, cut it into chips, and accurately weigh 0.018g in a 250mL round-bottomed flask. The air in the round-bottomed flask was purged with nitrogen gas, a grain of iodine was added into the flask as an initiator, and tetrahydrofuran and 3,5-dimethylbromobenzene were added dropwise into the flask. Stir the reaction until the magnesium chips disappear, that is, the MgO precursor 3,5-dimethylphenylmagnesium bromide is obtained. Accurately weigh 6g of ZSM-5 (SiO 2 / Al 2 o 3 =50), added to 150mL

[0010] Add the suspension to the freshly prepared Grignard reagent under the condition of passing nitrogen through the reaction system, stir and reflux at 80°C for 4 hours, and then evaporate the n-hexane solution to dryness. The obtained samples were baked at 120°C for 2 hours, calcined at 500°C for 8 hours, and air was ventilated during the whole process. MgO / Z...

Embodiment 2

[0011] Example 2: Grind off the oxides on the surface of the magnesium strip with sandpaper to reveal a bright metallic color, cut it into chips, and accurately weigh 0.0288g in a 250mL round-bottomed flask. The air in the round-bottomed flask was purged with nitrogen gas, a grain of iodine was added into the flask as an initiator, and tetrahydrofuran and 3,5-dimethylbromobenzene were added dropwise into the flask. Stir the reaction until the magnesium chips disappear, that is, the MgO precursor 3,5-dimethylphenylmagnesium bromide is obtained. Accurately weigh 6g of ZSM-5 (SiO 2 / Al 2 o 3 =50), was added to 150mL of n-hexane solution, and was prepared into a suspension, and this suspension was added to the Grignard reagent just prepared under the condition that the reaction system was ventilated with nitrogen, stirred and refluxed at 80°C for 4h, and then The n-hexane solution was evaporated to dryness. The obtained samples were baked at 120°C for 2 hours, calcined at 500°...

Embodiment 3

[0012] Example 3: Grind off the oxides on the surface of the magnesium strip with sandpaper to reveal a bright metallic color, cut it into chips, and accurately weigh 0.036g in a 250mL round-bottomed flask. The air in the round-bottomed flask was purged with nitrogen gas, a grain of iodine was added into the flask as an initiator, and tetrahydrofuran and 3,5-dimethylbromobenzene were added dropwise into the flask. Stir the reaction until the magnesium chips disappear, that is, the MgO precursor 3,5-dimethylphenylmagnesium bromide is obtained. Accurately weigh 6g of ZSM-5 (SiO 2 / Al 2 o 3 =50), was added to 150mL of n-hexane solution, and was prepared into a suspension, and this suspension was added to the Grignard reagent just prepared under the condition that the reaction system was ventilated with nitrogen, stirred and refluxed at 80°C for 4h, and then The n-hexane solution was evaporated to dryness. The obtained samples were baked at 120°C for 2 hours, calcined at 500°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com