Laser welding method capable of avoiding slag inclusion and improving laser absorptivity of aluminum alloy

A laser welding, aluminum alloy technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of slag inclusion, welding defects, affecting the application of laser welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 5083 aluminum plate is selected as the material to be welded.

[0028] (1) Use an angle grinder or a metal brush to remove the oxide film on the surface and then clean it with acetone;

[0029] (2) Carry out anodic oxidation in phosphoric acid solution, 250g / L phosphoric acid, 25°C, current density 1.2A / dm 2 , the oxidation time is 5 minutes;

[0030] (3) Reverse the voltage of step (2) for 3 minutes;

[0031] (4) Dye the oxide film on the surface of the sample with nigrosine black at a concentration of 10g / L at room temperature for 5 minutes;

[0032] (5) Drying with a hair dryer;

[0033] (6) After being welded out, the solvent for coating and removing the oxide film, the weight ratio of the solvent is 50% KCl, 28% NaCl, 12% LiCl 3 , 10%NaF. Coat the place to be welded with acetone;

[0034] (7) Then use CO 2 The gas laser is used for welding, the power range is 2.5KW, and the scanning speed is 200mm per minute.

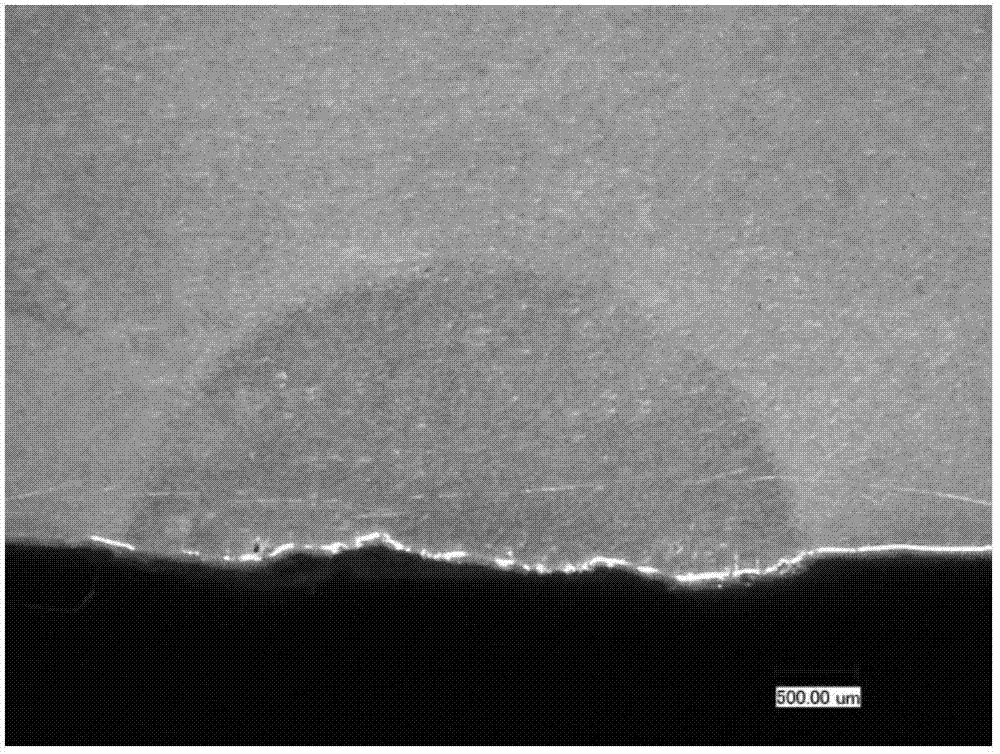

[0035] figure 1 It is the penetration depth o...

Embodiment 2

[0037] 5083 aluminum plate is selected as the material to be welded.

[0038] (1) Use an angle grinder or a metal brush to remove the oxide film on the surface and then clean it with acetone;

[0039] (2) Carry out anodic oxidation in phosphoric acid solution, 280g / L phosphoric acid, 25°C, current density 1.5A / dm 2 , the oxidation time is 4 minutes;

[0040] (3) Reverse the voltage of step (2) for 2 minutes;

[0041] (4) Dye the oxide film on the surface of the sample with nigrosine, the concentration is 15g / L, room temperature, and the dyeing time is 4 minutes;

[0042] (5) Drying with a hair dryer;

[0043] (6) After being welded out, the solvent for coating and removing the oxide film, the weight ratio of the solvent is 52%KCl, 26%NaCl, 11%LiCl 3 , 11%NaF. Coat the place to be welded with acetone;

[0044] (7) Then use CO 2 The gas laser is used for welding, the power range is 3.5KW, and the scanning speed is 300mm per minute.

Embodiment 3

[0046] 5083 aluminum plate is selected as the material to be welded.

[0047] (1) Use an angle grinder or a metal brush to remove the oxide film on the surface and then clean it with acetone;

[0048] (2) Carry out anodic oxidation in phosphoric acid solution, 290g / L phosphoric acid, 25°C, current density 1.6A / dm 2 , the oxidation time is 4 minutes;

[0049] (3) Reverse the voltage of step (2) for 3 minutes;

[0050] (4) Dye the oxide film with acid black, the concentration is 17g / L, room temperature, and the dyeing time is 4 minutes;

[0051](5) Drying with a hair dryer;

[0052] (6) After being welded out, the solvent for coating and removing the oxide film, the weight ratio of the solvent is 45%KCl, 30%NaCl, 15%LiCl 3 , 10%NaF. Coat the place to be welded with acetone;

[0053] (7) Then weld with a solid-state laser, the laser power is 1Kw, and the scanning speed is 250mm per minute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com