Porous carbon material and method for preparing same

A technology of porous carbon materials and polytetraphenylmethane, which is applied in the field of preparation of porous carbon materials and porous carbon materials, can solve the problems of cumbersome preparation process, high cost, and long preparation cycle, and achieve uniform pore size distribution, high specific surface area, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The porous carbon material was prepared according to the following steps.

[0084] Step 1: Synthesis and preparation of a porous organic framework material with ultra-high specific surface area - polytetraphenylmethane:

[0085] (1) Add 1g of nickel bis-1,5-cyclooctadiene, 0.568g of 2,2-bipyridine and 0.4mL of 1,5-cyclooctadiene into 1mL of N,N-dimethylformamide solution, Put it into an oil bath preheated to 60°C to age the catalyst for 0.5-3 hours;

[0086] (2) Subsequently, 3 mL of 0.2M p-bromotetraphenylmethane in N,N-dimethylformamide was reacted at this temperature for 60 hours, and the reaction was stopped;

[0087] (3) Add concentrated hydrochloric acid to the reaction system to destroy excess 1,5-cyclooctadiene nickel, and filter to obtain a white precipitate;

[0088] (4) Wash with hot solutions of 100mL water, 100mL ethanol and 100mL chloroform to remove inorganic salts and soluble organic matter;

[0089] (5) The final product was vacuum dried at 80-200°C ...

Embodiment 2

[0102] The method of this example is basically the same as that of Example 1, except that the active temperature in this example is 600°C.

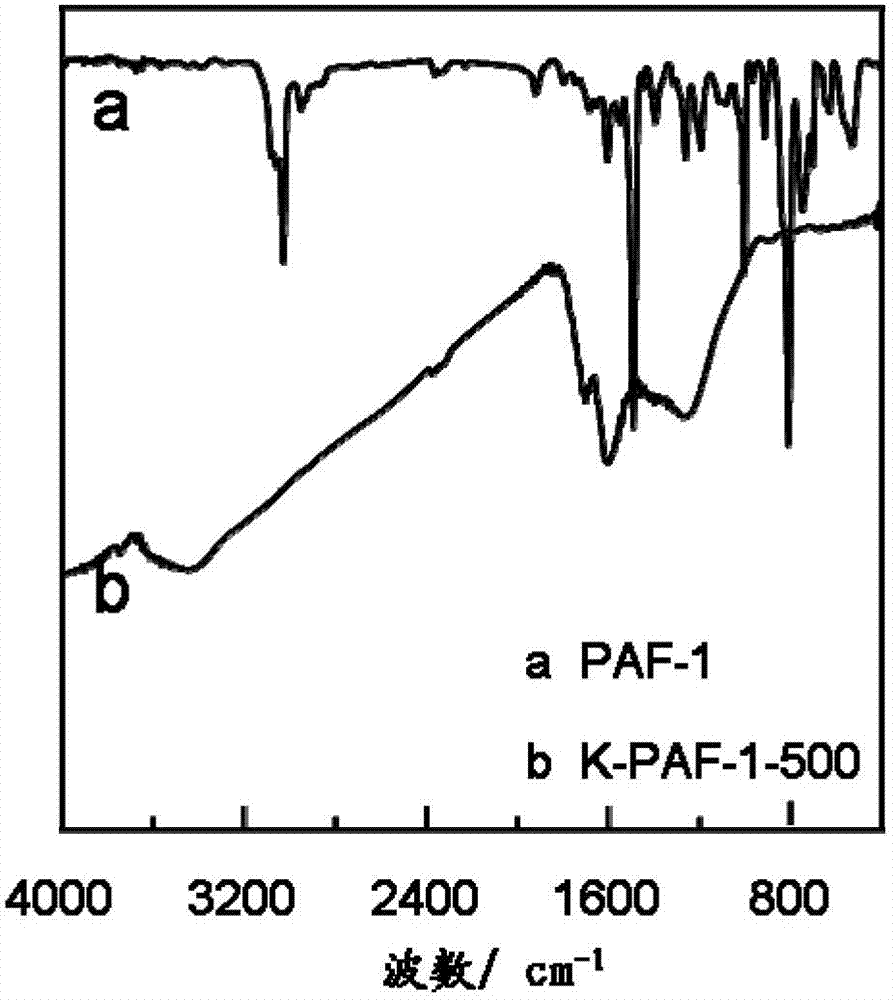

[0103] Figure 8 It is the 4000 cm of the porous carbon material prepared by the method of this example and its precursor polytetraphenylmethane -1 up to 400 cm -1 Infrared spectrum, where line a is the 4000 cm of the precursor polytetraphenylmethane -1 up to 400 cm -1 Infrared spectrum, line b is 4000 cm of porous carbon material -1 up to 400 cm -1 Infrared spectra. Such as Figure 8 As shown, there are only two weak broad peaks in the infrared spectrum of the porous carbon material prepared by the method of this example, corresponding to the stretching vibration of the carbon-carbon double bond, and no carbon-hydrogen vibration can be observed, indicating that the activation is very thorough.

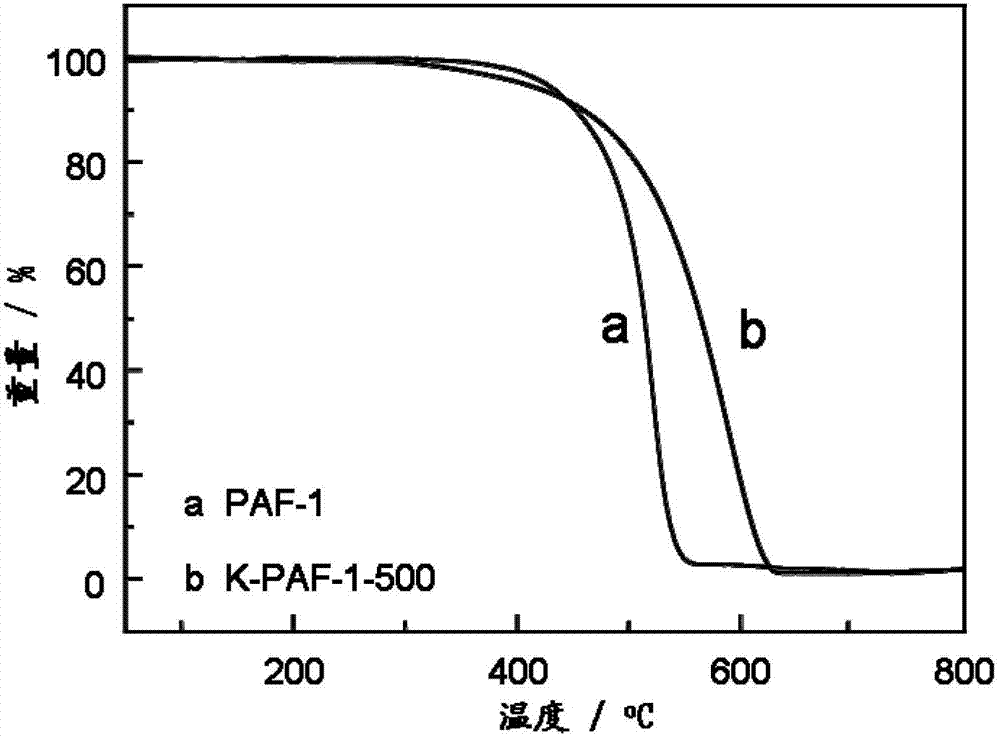

[0104] Figure 9 It is the thermogravimetric curve of the porous carbon material prepared by the method of this example and the pr...

Embodiment 3

[0110] The method of this example is basically the same as that of Example 1, except that the active temperature in this example is 700°C, and the heating rate of the temperature program in step 3 is 2°C / min.

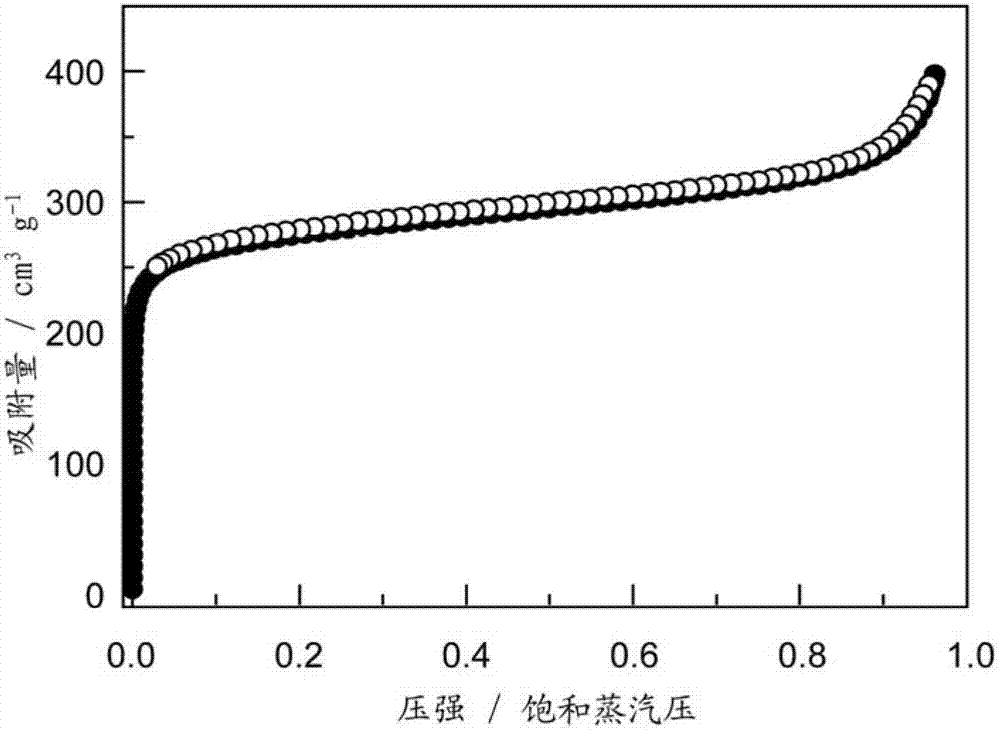

[0111] Figure 15-18 They are the infrared spectrum, thermogravimetric spectrum, nitrogen adsorption and desorption and pore size distribution diagram of the porous carbon material obtained in this example. Such as Figure 15 As shown, after activation, the hydrocarbon vibration at 800 wavenumber of the sample obviously disappears, showing the infrared spectrum of a typical carbon material. Such as Figure 16 As shown, the porous carbon material of this example has a 5% weight loss in dry air at about 480°C, and its thermal stability is significantly better than that of the precursor polytetraphenylmethane and the porous carbon materials of Examples 1 and 2, indicating that with the As the activation temperature increased, the thermal stability of porous carbon mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com