Cheap modified paint self-cleaning coating with super-hydrophobicity and preparation method and application thereof

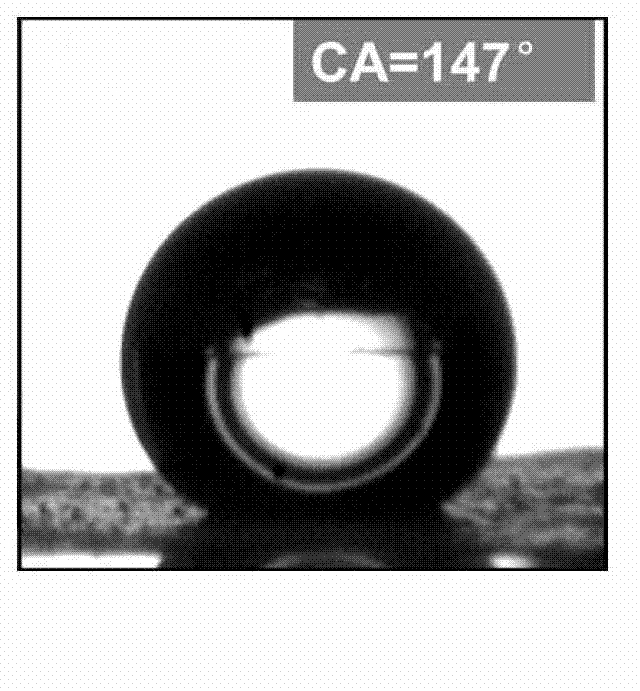

A self-cleaning coating and super-hydrophobic technology, applied in the field of paint and coating, can solve the problems of high cost and complicated preparation process, and achieve the effect of low cost, good repeatability and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

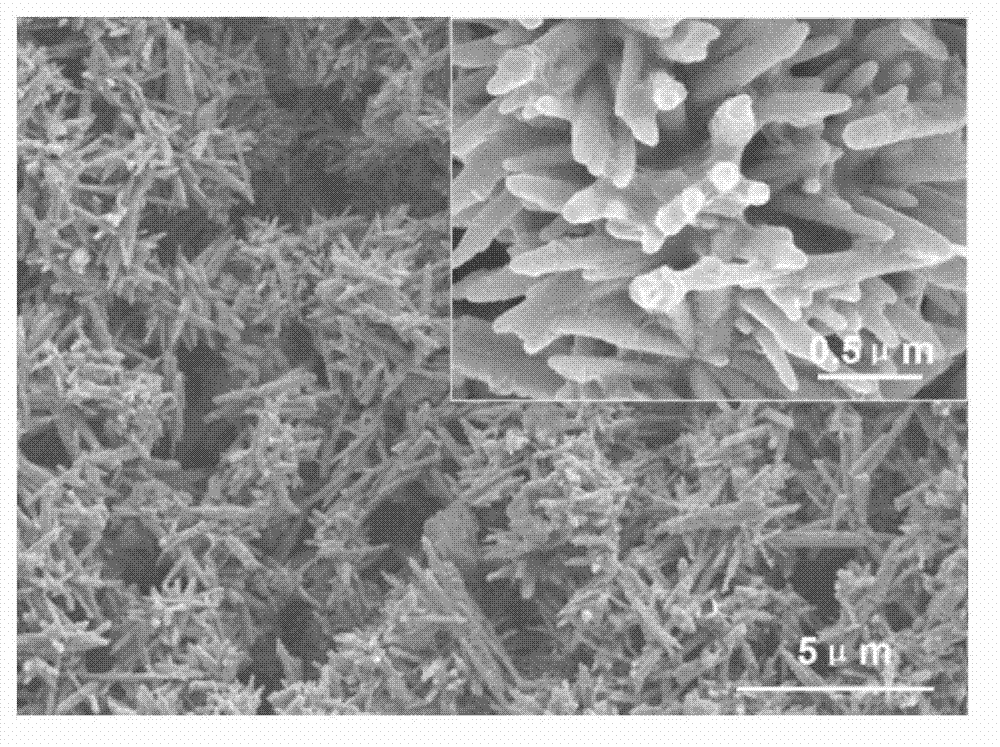

[0032] (1) Preparation of ZnO micro-nano composite structure particles: take a solution of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.5mol / L hexamethylenetetramine solution (C 6 h 12 N 4 , HMT) each 200ml ultrasonic, ultrasonic power 80W, ultrasonic time 30min, mix, stir for a period of time; then put the mixed solution in a water bath at 90 ℃ for 2 hours and take it out; after cooling to room temperature, pour off the supernatant , take out the white ZnO particles generated at the bottom, and then ultrasonically disperse them with ethanol, the ultrasonic power is 80W, the ultrasonic time is 10min; centrifuge at 8000rpm for 5min, pour off the supernatant, after ultrasonic cleaning, dry in a drying oven to obtain a white solid powder That is, ZnO micro-nano composite structure particles (the ZnO micro-nano composite structure particles are dandelion-shaped ZnO particles, and their external dimensions are about 5 microns, with nano-branch structures inside);

[00...

Embodiment 2

[0041] (1) Preparation of ZnO micro-nano composite structure particles:

[0042] Take 100ml concentration of 0.1mol / L zinc nitrate hexahydrate solution (Zn(NO 3 ) 2 ·6H 2 O) and 200ml concentration of 0.1mol / L hexamethylenetetramine solution (C 6 h 12 N 4 , HMT) for mixed ultrasound (if a large number of preparations are made, the above ratio will not change), the ultrasonic power is 40W, the ultrasonic time is 50min, mixed and stirred for a period of time; then the mixed solution is placed in a water bath at 95°C for 1 hour and taken out; Pour off the supernatant after cooling at room temperature, take out the white ZnO particles formed at the bottom, and then disperse them by ultrasonication with ethanol. Dried in a drying oven to obtain a white solid powder that is ZnO micro-nano composite structure particles;

[0043] (2) Preparation of modified paint solution:

[0044] Disperse 2 g of dandelion-shaped ZnO micro-nano composite structure particles prepared in Example...

Embodiment 3

[0049] (1) Preparation of ZnO micro-nano composite structure particles:

[0050] Take a concentration of 0.1mol / L zinc nitrate hexahydrate solution (Zn(NO 3 ) 2 ·6H 2 O) and 0.1mol / L hexamethylenetetramine solution (C 6 h 12 N 4 , HMT) each 300ml for ultrasonication (if a large number of preparations, the above ratio remains unchanged), the ultrasonic power is 40W, the ultrasonic time is 60min, mixed and stirred for a period of time; then the mixed solution is placed in a water bath at 50°C for 3 hours and taken out Pour off the supernatant after cooling at room temperature, take out the white ZnO particles generated at the bottom, and then ultrasonically disperse them with ethanol, the ultrasonic power is 50W, and the ultrasonic time is 60min; centrifuge at 6000rpm for 5min, pour off the supernatant, and after ultrasonic cleaning, Place it in a drying oven to dry, and obtain a white solid powder that is a ZnO micro-nano composite structure particle (the ZnO micro-nano co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com