High-strength PU compound A-level fireproof heat-insulating pate and preparation method thereof

A fire-proof insulation board, high-strength technology, applied in the field of polyurethane foam, can solve the problems of poor overall strength and flame retardant effect, and achieve the effect of ensuring service life and safety in use, smooth surface and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

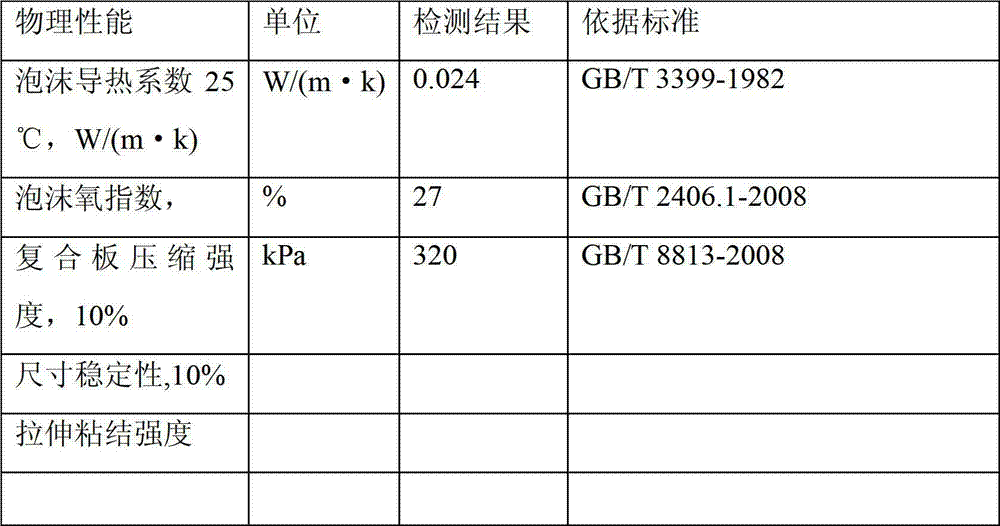

Embodiment 1

[0033] 1 Using cement glass fiber veneer material processing equipment, uniformly mix cement, inorganic gel material, organic gel material, flame retardant, etc. at a mass ratio of 1:0.5:1:0.5 and coat both sides of the glass fiber mesh cloth After being made into a cement glass fiber veneer coil, it is ready for use.

[0034] 2 Mix polyether polyol, flame-retardant polyether polyol, catalyst, stabilizer, foaming agent, flame retardant, etc. according to the mass ratio of 50:50:3.6:2.4:25:28 to prepare high-functionality combined polyether And pump it into the storage tank of the plate production line and stabilize it to 30°C for use. Polymerized MDI is pumped into another storage tank and stabilized to 30°C for use.

[0035] 3Using the automatic plate production line, place the cement glass fiber veneer material on the upper and lower chains of the equipment. According to the thickness and density of the plate, adjust the distance between the upper and lower chains to be 50m...

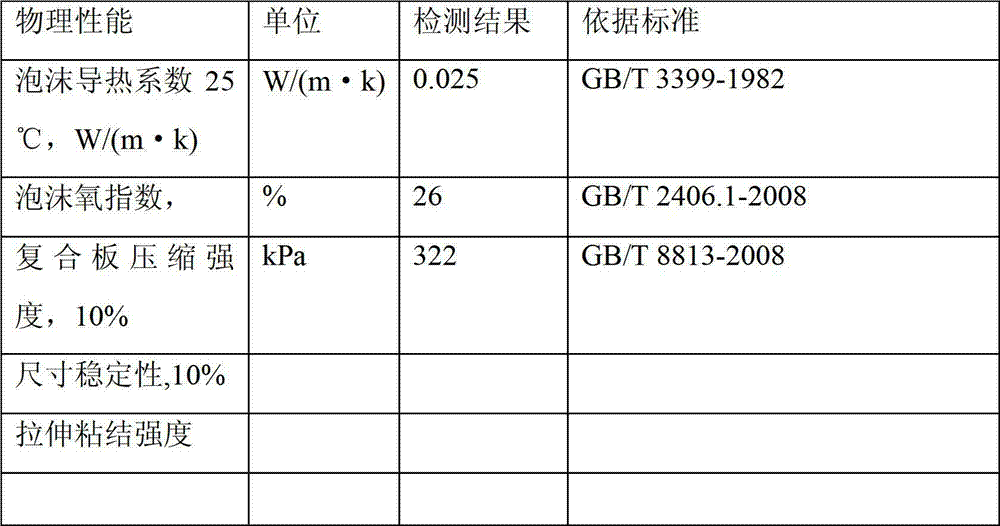

Embodiment 2

[0050] 1 Using cement glass fiber veneer material processing equipment, uniformly mix cement, inorganic gel material, organic gel material, flame retardant, etc. at a mass ratio of 1:0.5:1:0.5 and coat both sides of the glass fiber mesh cloth After being made into a cement glass fiber veneer coil, it is ready for use.

[0051] 2 Mix polyether polyol, flame-retardant polyether polyol, catalyst, stabilizer, foaming agent, flame retardant, etc. according to the mass ratio of 40:60:2:5:15:17 to prepare high-functionality combined polyether And pump it into the storage tank of the plate production line and stabilize it to 30°C for use. Polymerized MDI is pumped into another storage tank and stabilized to 30°C for use.

[0052] 3 Using the automatic plate production line, place the cement glass fiber veneer material on the upper and lower chains of the equipment. According to the thickness and density of the plate, adjust the distance between the upper and lower chains to be 50mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com