Constant-pressure hot water module for ships

A technology for hot water and ships, which is applied in the field of marine constant pressure heat exchange modules. It can solve the problems of loss, increase of steam pipelines of steam heaters, and easy corrosion of system devices, so as to set the pressure of the water system, supplement the water volume of the system, The effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

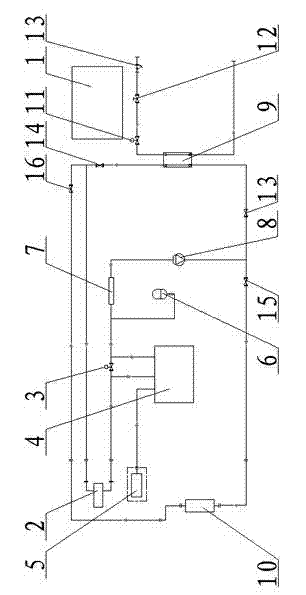

[0015] figure 1 As shown, a constant pressure hot water module for a ship includes a control box 1, an indirect air conditioner 2, a solenoid valve 3, a vacuum jet exhaust device 4, a water supply piping system 5, a constant pressure expansion tank 6, and an ionized water treatment instrument 7. Water pump 8, plate heat exchanger 9, water chiller 10, steam flow regulating valve 11, butterfly valve 12 and steam filter 13. One end of the indirect air conditioner 2 is sequentially connected to the constant pressure expansion tank 6, ion water treatment instrument 7 and water pump 8 through the solenoid valve 3, and a vacuum jet exhaust device 4 is connected in parallel to both ends of the solenoid valve 3, and the vacuum jet exhaust device is connected externally There is a water supply pipe system 5, and the water pump 8 is connected to the heat-absorbing end of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com