Method for synthesizing SiO2 lithium ion battery cathode material lithium titanate

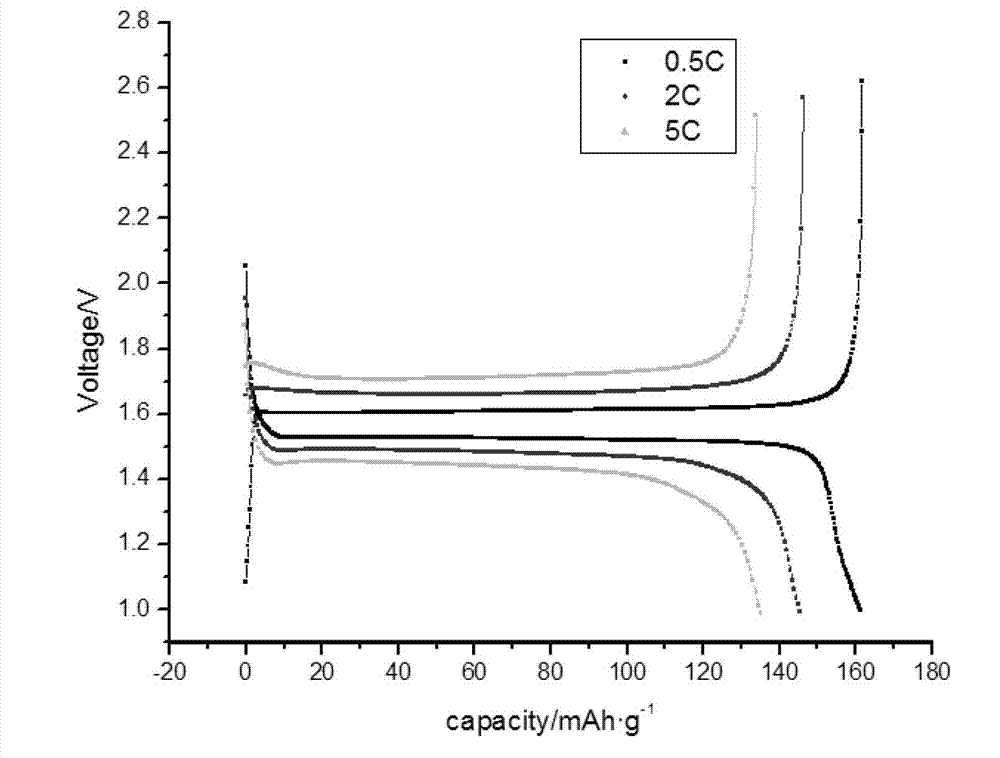

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, titanium compounds, etc. problem, to achieve the effect of improving rate performance and cycle performance, particle size, and high charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

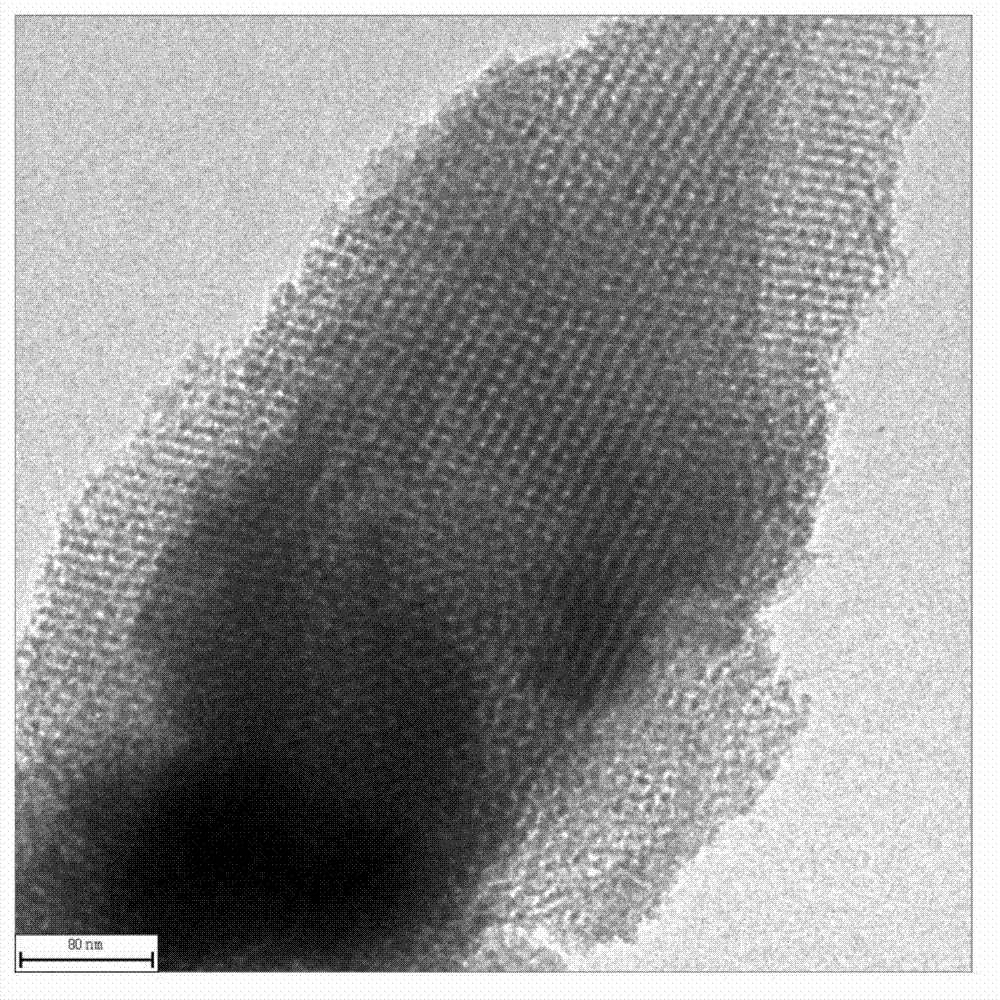

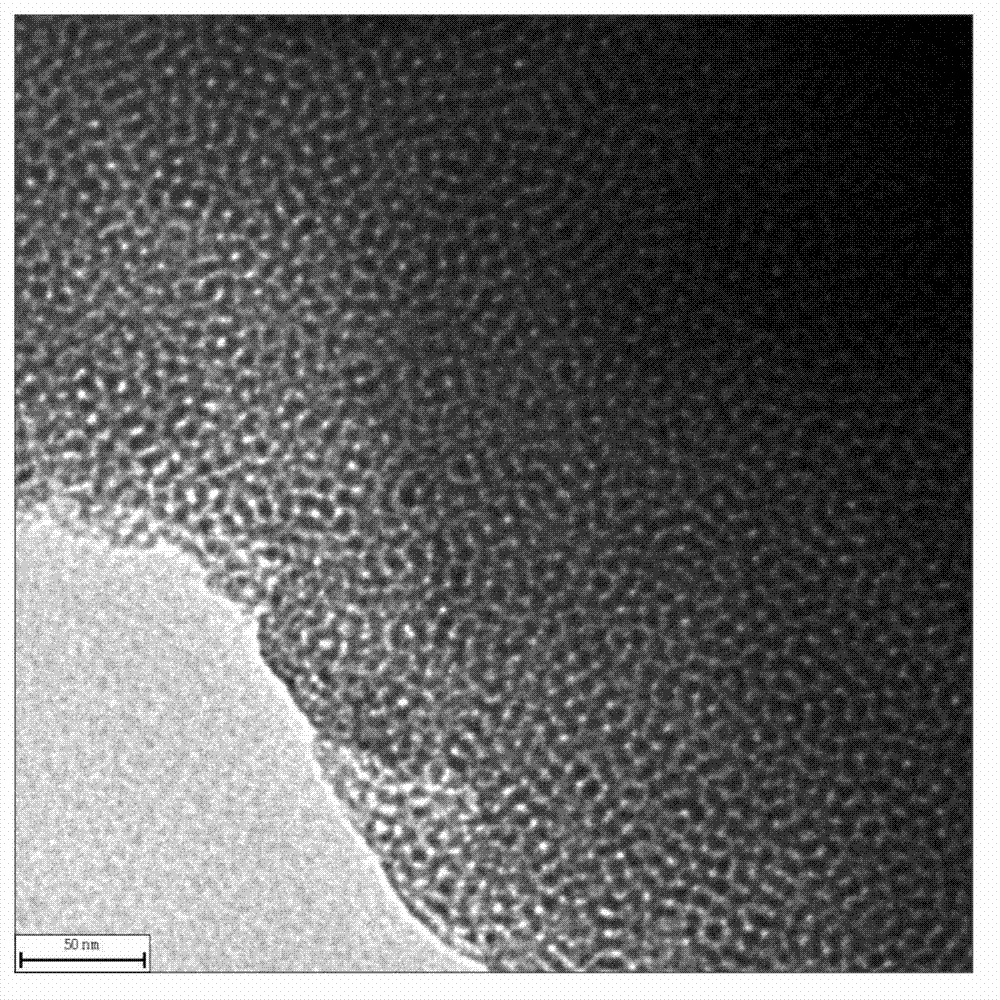

[0021] (1) Weigh the corresponding stoichiometric precursor according to the molar ratio of 0.0172 P123: 1TEOS: 6HCl, dissolve P123 in deionized water, stir until it is completely dissolved, then add 2mol / L hydrochloric acid, and stir for 3 hours with slight heat; Slowly add TEOS dropwise. After the dropwise addition, stir at high speed in a water bath at 30°C for 24h, then transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallize at 100°C for 24h; Wash until neutral, and dry at 100°C; heat the synthesized material to 550°C at a rate of 1°C / min in a muffle furnace, and keep it warm for 16 hours to obtain SiO with nanopores. 2 template. Nanoporous SiO 2 The scanning electron microscope image of the template is shown in figure 1 shown.

[0022] (2) Weigh a certain amount of lithium acetate and tetrabutyl titanate with a molar ratio of Li:Ti of 4.2:5, disperse them in anhydrous ethanol solvent, and slowly add them dropwise to SiO 2 On t...

Embodiment 2

[0024] (1) Weigh the corresponding stoichiometric precursor according to the molar ratio of 0.0172 P123: 1TEOS: 6HCl, dissolve P123 in deionized water, stir until it is completely dissolved, then add 2mol / L hydrochloric acid, and stir for 3 hours with slight heat; Slowly add TEOS dropwise. After the dropwise addition, stir at high speed in a water bath at 40°C for 24h, then transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallize at 100°C for 24h; the obtained product is deionized Wash with water until neutral, and dry at 100°C; heat the synthesized material to 600°C in a muffle furnace at a rate of 1°C / min, and keep it warm for 12 hours to obtain SiO with nanopores. 2 template.

[0025] (2) Weigh a certain amount of lithium oxalate and methyl titanate with a molar ratio of Li:Ti of 4.2:5, disperse them in anhydrous ethanol solvent, and slowly add them dropwise to SiO at 120°C. 2 On the template, the precursor is obtained after evapora...

Embodiment 3

[0027] (1) Weigh the corresponding stoichiometric precursor according to the molar ratio of 0.0172 P123: 1TEOS: 6HCl, dissolve P123 in deionized water, stir until it is completely dissolved, then add 2mol / L hydrochloric acid, and stir for 3 hours with slight heat; Slowly add TEOS dropwise. After the dropwise addition, stir at high speed in a water bath at 30°C for 24h, then transfer to a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallize at 100°C for 24h; Wash until neutral, and dry at 100°C; heat the synthesized material to 550°C at a rate of 3°C / min in a muffle furnace, and keep it warm for 16 hours to obtain SiO with nanopores. 2 template.

[0028] (2) Weigh a certain amount of lithium acetate and methyl titanate with a molar ratio of Li:Ti of 4.1:5, disperse them in anhydrous ethanol solvent, and slowly add them dropwise to SiO at 120°C. 2 On the template, the precursor is obtained after evaporating the solvent; the resulting mixture is si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com